underground becomes a major hurdle.

The solutions come from the experience

and expertise held in those few countries

in the world with a long history of

extracting deep coal. In such cases, the

experience and accumulated knowledge

gained in deep coal basins, such as the

Ruhr in Germany, where mining

activities have been carried out

successfully in extreme conditions, can

be extremely illuminating.

History of the subject

The high levels of productivity that can

be obtained through the application of

modern longwall mining technology is as

dependent on the long-term stability of

access roadways and of the coalface

T‑junction, as it is on the effectiveness of

the hydraulic supports and equipment

used at the face. Even minor disruption to

the state of the roadways can cause

serious disturbances to the production

process and, consequently, a loss of

productivity. This becomes vitally

important when mining at great depth

and/or multi‑seam extraction sequences.

Since the 1950s, DMT has been

deeply involved in carrying out research

in the field of rock mechanics associated

with the extraction of multiple and

extremely deep coal seams.

Initially, DMT’s major R&D activities

were conducted predominantly at

German mines but, over the years, the

R&D programmes have gradually been

extended to other coalfields outside of

Germany, such as Russia, Ukraine,

Czech Republic, Australia, Kazakhstan

and others.

The focus of the research has been on

how the coal seams and overlying strata

react before, during and after coal

extraction takes place at depth.

Particular aspects that have been

investigated include rock movements,

rock pressure and stress distribution

around production areas and the effects

at surface, rock deformation around

roadway and underground openings,

methods to improve roadway stability

and the development and continual

improvement of innovative modern

support solutions. During this very

thorough process, a range of strata

support materials and techniques have

been studied and evaluated.

The development and proving of

effective operational systems has been

ongoing in Germany over many years

and is summarised below, together

with an explanation of the importance

of efficient rock pressure management

for the strategic development of the

mine.

Support technologies and

design parameters

The basic purpose of roadway support

systems at shallow depth is to protect

miners from falls of ground. Around the

world, many of the roadways driven in

coal mines are rectangular in shape,

ideally suited to modern high-speed

development and production

equipment. However, with increased

depth of extraction, new roadway

support systems have had to be

developed, as previous solutions do not

cope with the increasingly challenging

rock and stress conditions encountered

at extreme depths.

In the ultra‑deep German mines,

rectangular shaped roadways suffer

extreme deformations. In quite a

number of cases, such deformation and

stress release events can be sudden,

uncontrolled and occur directly after

advance of the face supports. The

traditional design of roadways did not

account for the changing geotechnical

conditions caused by the depth of

operations.

The primary function of roadway

support is to maintain the shape and

cross-section of the mine roadway and

withhold the load of the fracture zone

surrounding the roadway under all

conditions, ensuring a safe working area

for the workforce. Increased surveillance

by the mining authorities in Germany

has led to the development and

adoption of new and more robust

support solutions there.

Although these have sometimes been

high-cost solutions, they have allowed

safe and effective mining operations to

take place even at extreme depths for

coal mining.

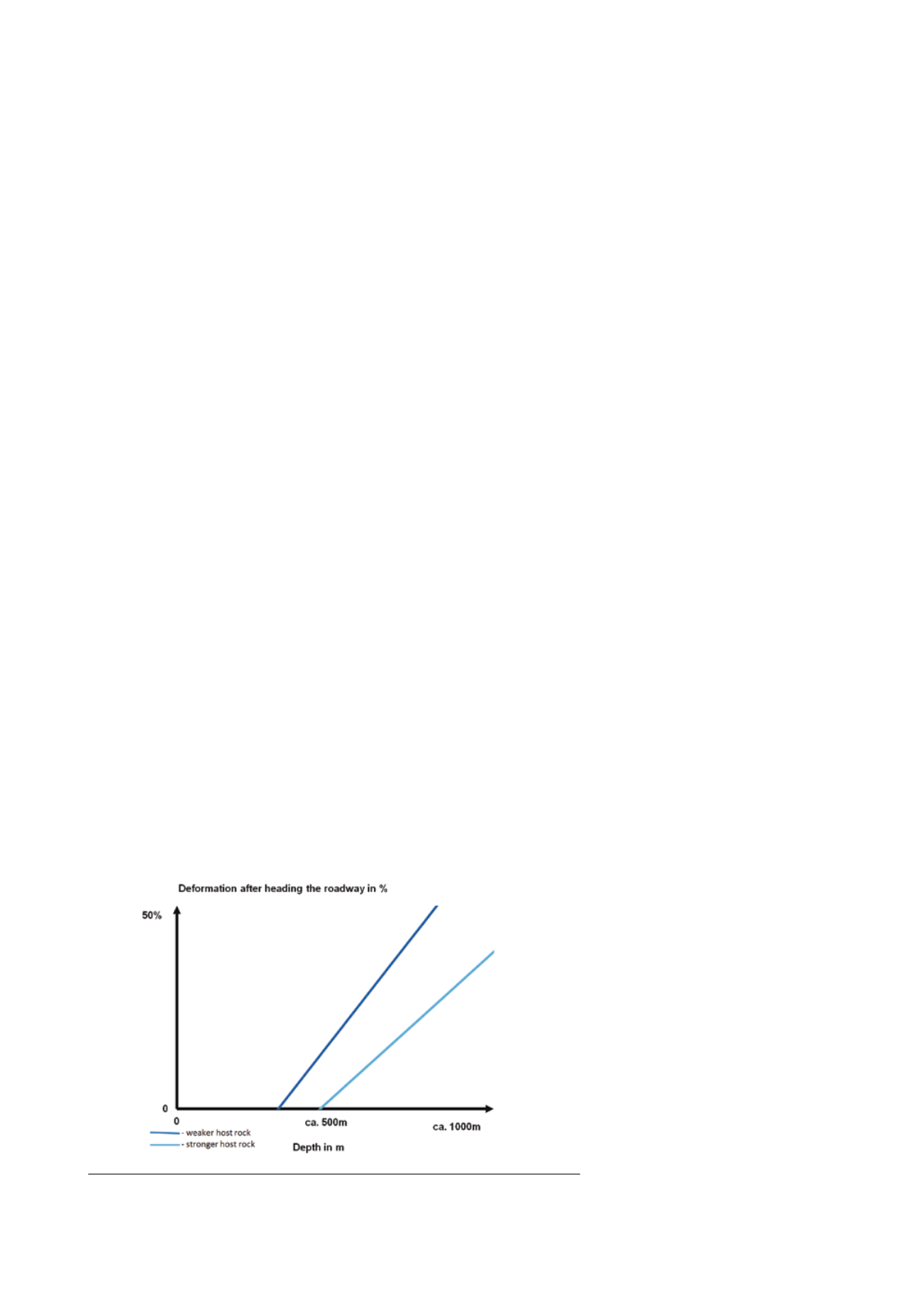

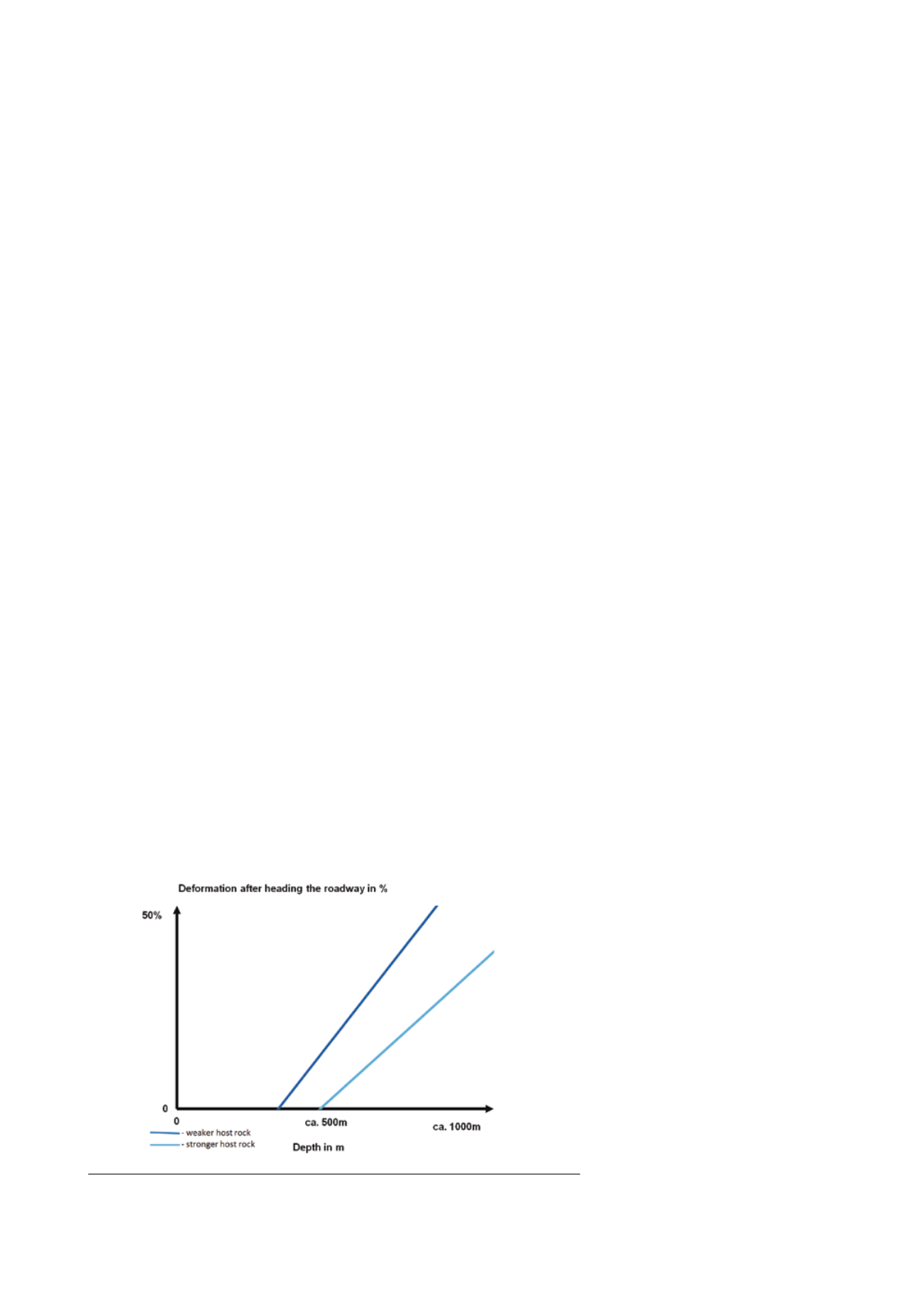

At greater depth, if roadways are not

supported immediately after advance,

they will be subject to large deformation

and convergence. The interrelationship

between depth, rock strength and

roadway deformation is shown in

Figure 2. In this chart, the Y‑axis shows

the deformation in the form of roadway

convergence immediately after advance.

The stronger the host rock is, the less is

the chance of roadway deformation

down to 500 m, however the presence of

weak host rock can cause such event

even at lower depth.

Over the length of a roadway, there

will typically be sections suffering very

little damage, while other sections may

be subject to extreme strata pressure and

deformation. Typically, this is driven by

interaction with neighbouring openings,

localised re-distribution of stresses and

the nature and characteristics of the

surrounding rock mass. Fracturing

extends well into the host rock and is not

limited to a fewmeters in the roof and

the floor. Depending on the structural

nature of the surrounding rock, folding

in the roof and the floor layers will also

occur. In this situation, the roadway will

Figure 1. Conditions for appearance of roadway deformations.

78

|

World Coal

|

August 2015