become deformed to the point where it

is no longer stable, which results in the

need to stop mining and repair the

roadway or, in extreme situations, may

even need a new roadway to be driven.

Extensive physical modelling, carried

out by DMT over the last two decades,

has allowed the company to establish

the nature and extent of such

deformation in the surrounding rock

mass and to create physical models to

demonstrate this deformation.

It is clearly important that the most

appropriate design of strata support is

adopted for the specific conditions

encountered, so that not only will the

roadway and workforce be protected

from roof falls, but also the deformation

will be reduced in order to maintain the

minimum cross-section necessary for the

operational needs.

In Germany, conventional yielding

arch supports have been used to depths

of up to 750 m. However, over time, it

has become clear that a support strategy

focused only on the minimisation of

support structure deformation does not

meet the support demands required at

greater depths. As a first step in

generating greater support rigidity,

backfilling with cementitious material

behind arch support was tested in the

deep German mines. Although this was

shown to be successful, the technique

was not considered to be viable due to

the time taken in setting up the support

structures, which is not compatible with

the increasing demand for speed of

advance.

The state-of-the-art technology used

today in the most highly stressed

roadways in German coal mines

involves the combination of rockbolting,

yielding arch support and arch

backfilling. Without this style of heavy

duty support, development of roadways

in coal mines depths of up to 1500 m

would not be possible.

With this method, rockbolts are

installed immediately after advancing

the roadway, as well as the use of other

methods of mass reinforcement. The

bolt density should be sufficient to

maintain stability of the roadway until

further support elements can be

installed. In the absence of this

immediate active support, it is unlikely

that deformation of the roadway can be

prevented.

Modern tools helping to

move support technology

forwards

Early methods of geotechnical

investigations, such as empirical

equations, were based on measurements

made in the mines and then correlated

with the geological conditions and

physical properties of the rock. Physical

models were used to further define the

basic parameters of the support system.

However, over the last 20 yr,

computerised numerical modelling

technologies have become increasingly

important and now lead the way in

analysing and optimising the support

solutions in current use. The application

of numerical methods becomes

extremely important when analytical

and empirical processes cannot provide

the required degree of accuracy because

of the existence of complex boundary

conditions.

For many years, DMT has used a

variety of numerical programmes for the

solution of different geomechanical

questions.

DMT employs numerical models for

a whole range of support design

assignments, such as:

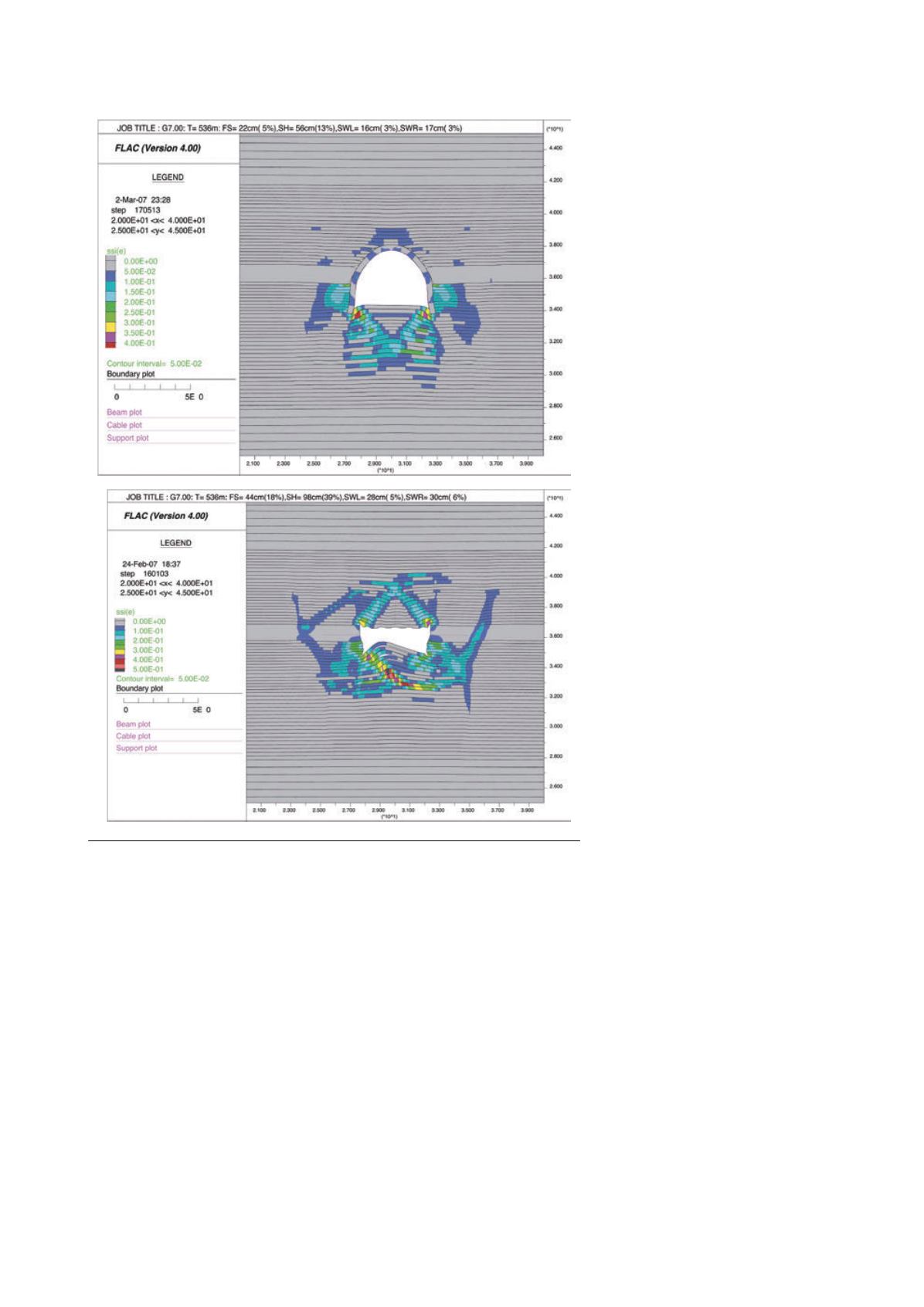

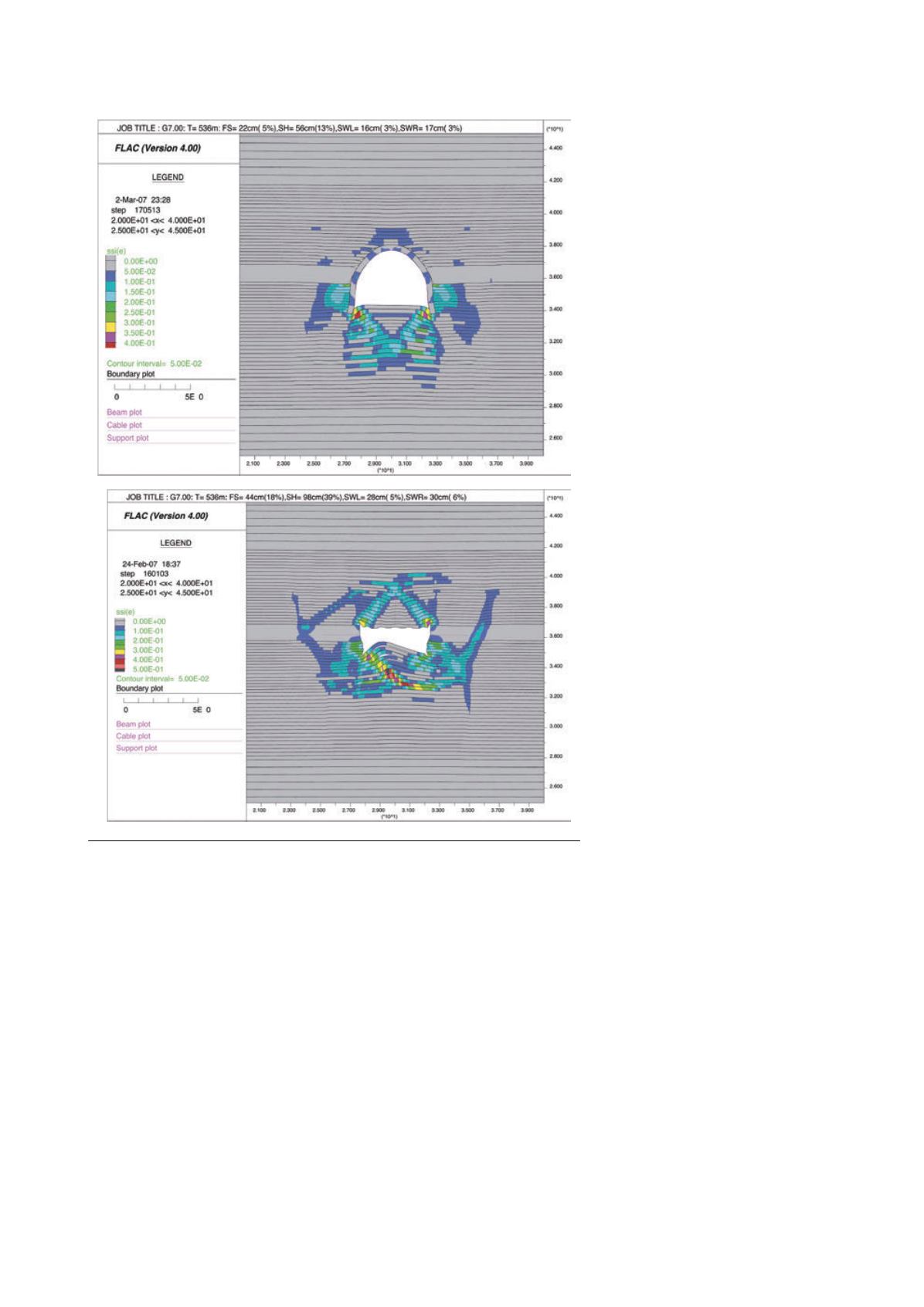

Figure 2. Numeric model in FLAC (Itasca). The top picture: arch shape with yielding

support with backfilling. The picture below: rectangular roadway with rock bolt support.

80

|

World Coal

|

August 2015