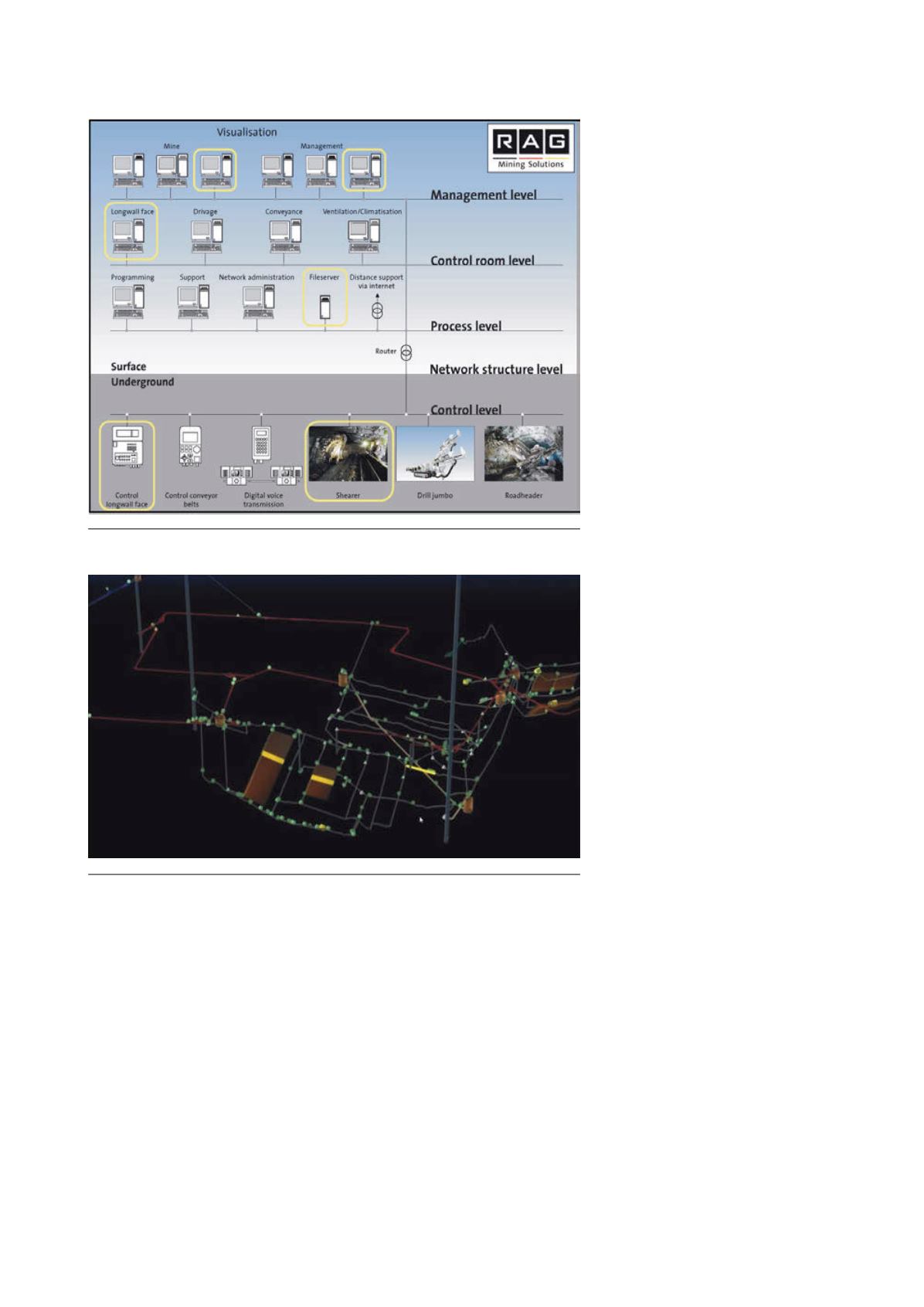

The intelligent face automation

system is now fully integrated into all

system levels at RAG coal mines as

part of the sustainable control room

technology provided by

RAG Mining Solutions. This

development, which is based on a

modern software architecture,

provides a uniform reporting regime

and is therefore a key element when it

comes to optimising operational

reliability, transparency and efficiency.

Figure 7 shows how the intelligent

face automation system is integrated at

all network levels. Its full integration

into the RAG Mining Solutions

self-sustaining control room system

therefore opens up possibilities that go

far beyond those afforded by the

individual module. These include:

n

Amanagement and information

system in line with latest practice,

based on 40 yr of mining experience

in improving and refining coal

winning operations under difficult

geological conditions at RAG mines.

n

Lower training needs and easier

instrument handling for real-time

control and process execution.

n

Manufacturer-neutral control using

a uniform visualisation system.

n

Standardised system with fewer

interfaces for project management.

n

Unified data structure makes for

easier integration into an ERP

system.

The combination of intelligent face

automation and self-sustaining mine

control technology is based on the

concept of the ‘control room of the

future’, a system that is already in

operation at Prosper-Haniel coal mine.

Here the control personnel have a

permanent overview of all operations

and processes under way above and

below ground. The possibility of

intervention anywhere and at any time,

in compliance with prescribed machine

safety standards, is one of the system’s

unique features.

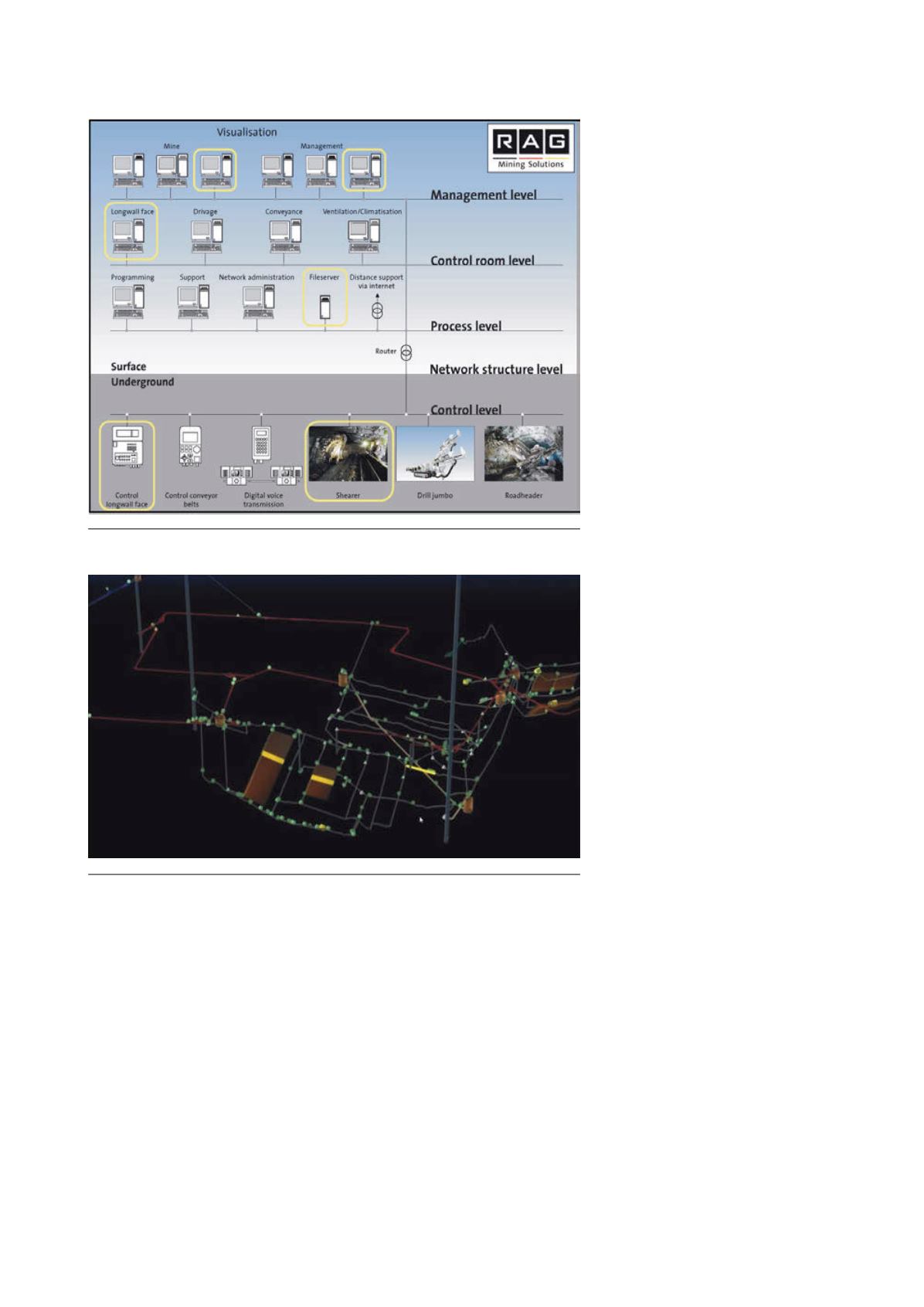

As well as managing the coal

winning process itself, the

self-sustaining control room system is

able to perform control actions based on

a 3D model of the mine workings

(Figure 8).

As well as providing a

multi-language user interface in English,

Russian, Polish and Chinese, this 3D

model can also be expanded to include

material tracking and personnel location

functions. Knowing the exact location of

each member of the underground

workforce constitutes a huge

improvement to workplace safety and

means that, if such a need should arise,

rescue actions can be coordinated from

the surface control room.

While this control room technology

has been designed for use at a coal mine

level, it is also suitable for the wider

mining industry and for industrial

applications.

Conclusion

When operating coal faces at deep

levels, a large degree of mining

experience is needed in order to manage

geological factors, such as rock pressure

and methane emissions, as safely as

possible. The example discussed in this

article concerns a longwall face in

Zollverein 1/2 seam at the RAG‑owned

Prosper-Haniel coal mine.

The main challenges facing the

production team, in addition to the

Figure 7. Process diagram.

Figure 8. 3D model of the mine workings.

74

|

World Coal

|

August 2015