n

n

Expertise in training personnel from

all parts of the industry.

Using the company’s own patents as

a basis, an intelligent face systemwas

developed and introduced in

collaboration with the group subsidiary,

RAGMining Solutions. This focused on

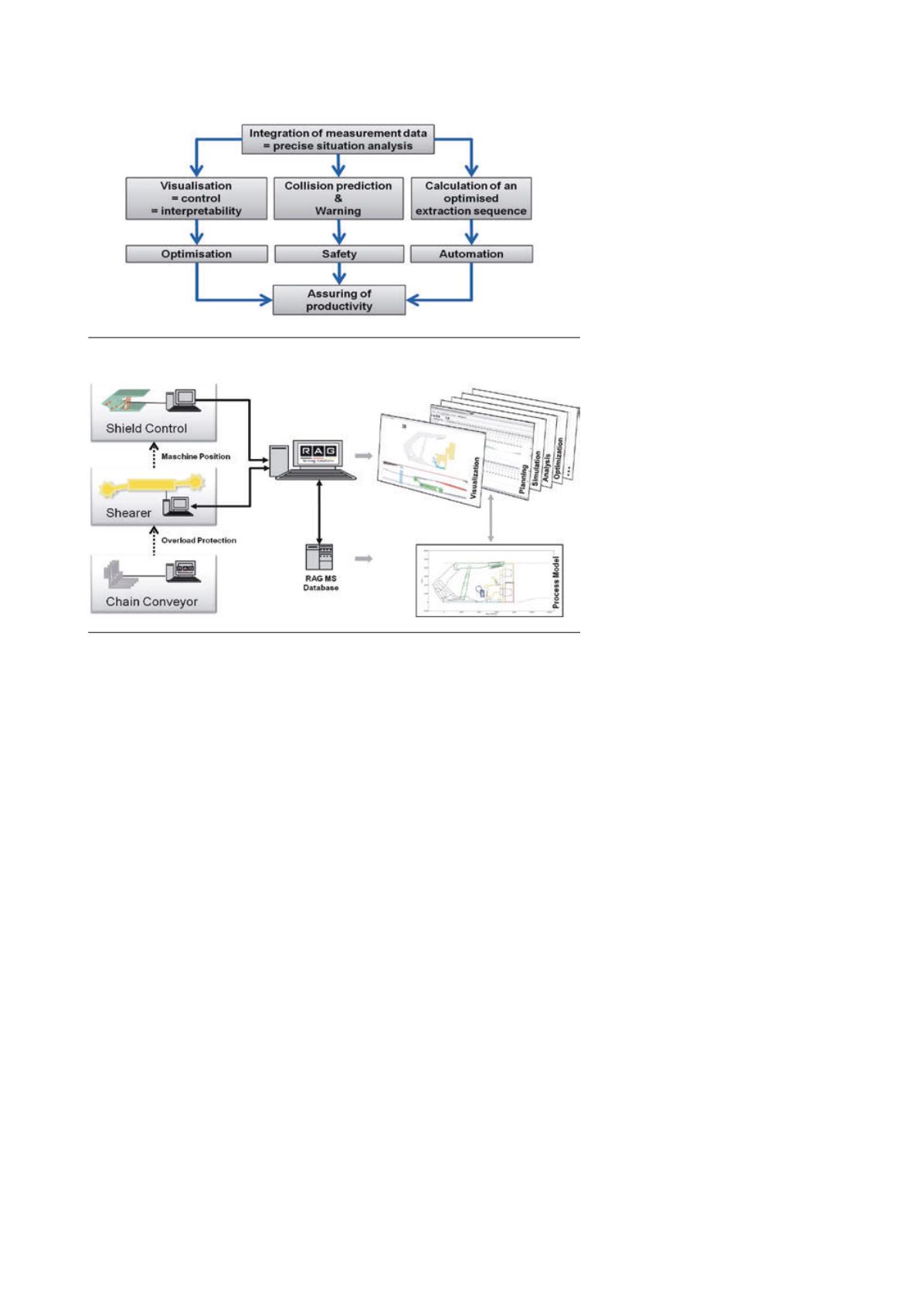

the key automation objectives shown in

Figure 1.

The system is designed to maintain

efficient coal winning, in conjunction

with high safety requirements, by

interlinking the key coal face

components (shearer-loader, face

conveyor and shield supports

with electrohydraulic control).

These components have already

been part-automated (automatic

machine travel and ranging-arm

operation, automatic shield support

sequence and automatic conveyor

pushing).

In order to employ the intelligent face

automation system, the face equipment

also has to meet the following

requirements:

n

n

The shearer-loader, which in

Germany is employed in working

thicknesses of 1.6 – 4.5 m, must

be fitted with sensors to monitor

ranging-arm position, machine

travel speed, machine position and

transverse and longitudinal tilt.

n

n

The face conveyor, operating in

conjunction with an IPC, must

be monitored for overload (using

current consumption, for example,

the StroMatic system). The rate of

advance is usually measured by

reed transducer, which detects the

amount of travel at the conveyor

advancing gear.

n

n

The electrohydraulic shield supports

must be fitted with a control

system that can perform automatic

shield operations as a function of

the shearer drum position. The

intelligent face automation system

also requires the installation height

to be calculated using inclination

sensors operating in conjunction

with the geometric data from all

of the load-bearing parts of the

support unit. When articulated

cantilever bars are being deployed,

the system has to be equipped with

angle sensors or reed transducers for

status monitoring purposes.

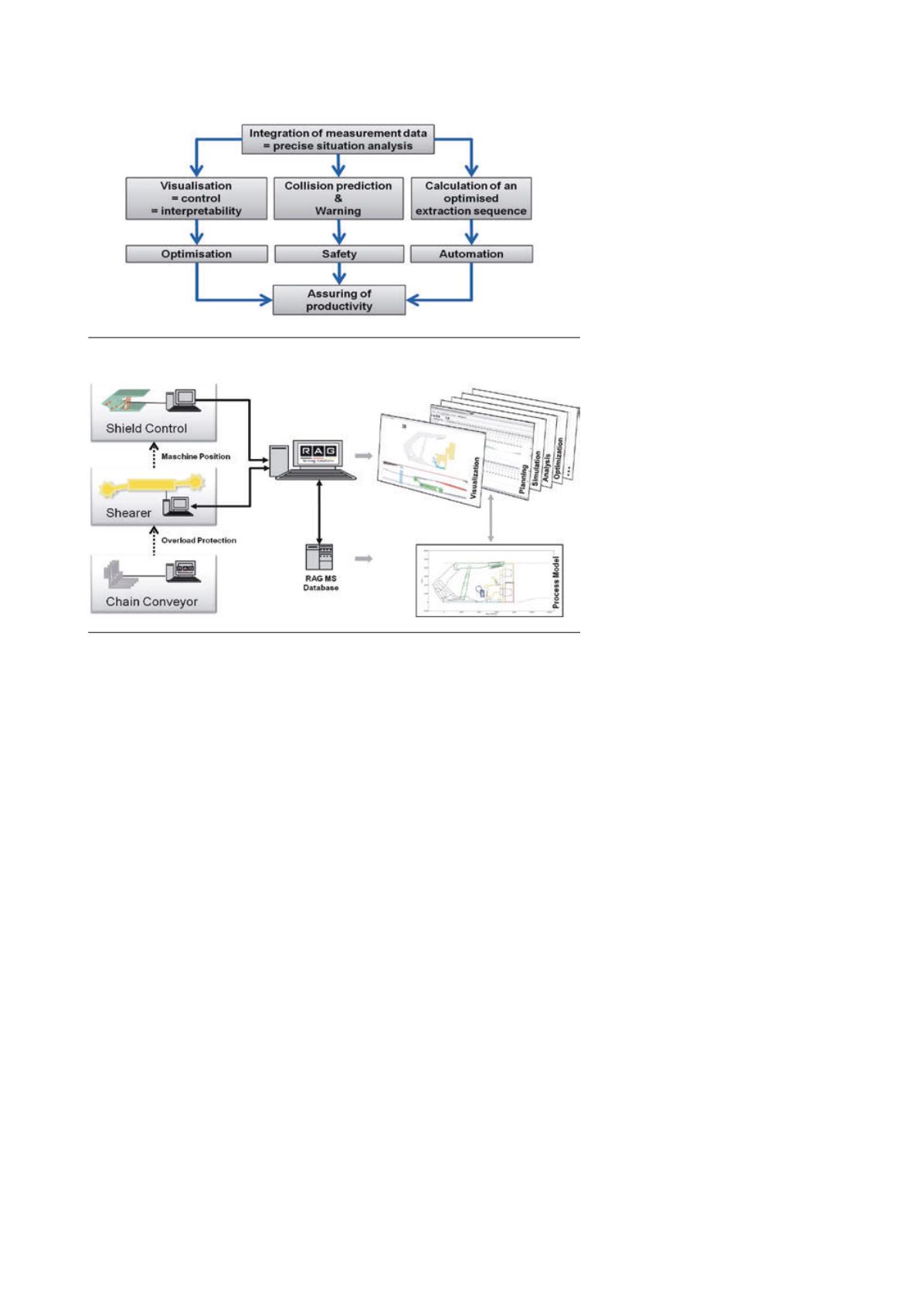

The left section of Figure 2 depicts the

semi-automated winning process as

described above.

Using this automation level as a

starting point, the intelligent face

automation system (shown in the central

part of Figure 2) combines all of the data

into an individual vector model. This is

the prerequisite for the subsequent

processing routine that is performed in

the process model (shown on the right

section of Figure 2), which provides the

coordinated interaction of the individual

components involved in the coal

winning process.

The data thus provided can be

combined with the geometric contours

to visualise each face situation that may

arise. By this means, it is possible to

perform distance calculations and issue

collision warnings, as well as provide

historic and predicted assessments of the

face situation.

This means that, as well as being able

to monitor each individual machine, the

control room operator is actively

involved in the winning process and can

support the on-face team in the

following ways:

n

n

Collision avoidance: this is a unique

feature of the intelligent face

automation system.

n

n

Optimisation of the face situation.

n

n

Reacting to critical loading situations

during coal clearance.

n

n

Setting up the next machine cut after

assessing the incoming sensor data

and collision calculation.

This software integration is the result

of an extensive survey of RAG

personnel, ranging frommachine

operators to engineering staff. Through

the provision of an expert system, the

loss of expertise resulting from the

reduction in manpower can be offset.

The system, as described above, was

introduced into the German coal

industry for the first time in 2015.

Extensive development work and

countless trials above and below ground

Figure 1. Automation objectives.

Figure 2. Part-automated face components and their integration into the intelligent

face automation system.

68

|

World Coal

|

August 2015