were needed in order to ensure that high

safety standards are constantly

maintained.

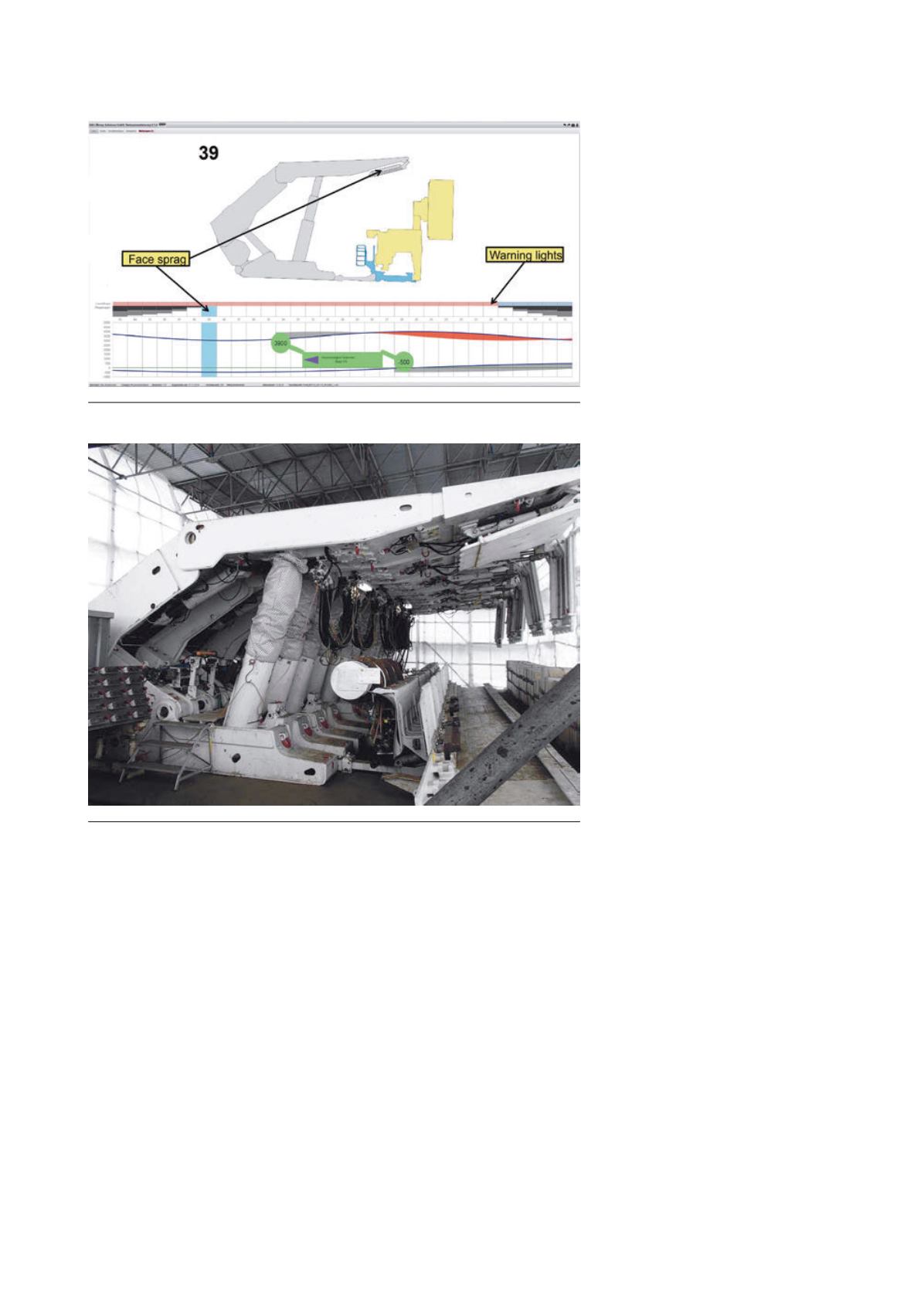

Figure 4 shows the testing and

training layout that was set up above

ground to carry out all of the different

performance tests and to provide a

learning and training facility for

machine operators, control station

personnel and face deputies.

The training face was used to test all

of the automatic functions before they

were installed and put into operation

below ground.

This short-face installation consisted

of seven powered-support units of

similar design in addition to those

already installed in the Zollverein panels

at Prosper-Haniel coal mine. A total of 20

additional support control devices were

also included on both the right and left

side of the test installation to simulate an

82 m long coal face.

Operating in conjunction with the

IPCs for the coal shearer and the

shield-support central control system

(face control centre), the surface

facility provided a set of realistic

conditions for testing the shield

automatic controls.

All of the development activity

associated with this particular

application called for a large amount of

fundamental research and feasibility

study work, the results of which are now

incorporated into a specific process

model that can also be transferred to

other production faces.

The experience thus acquired has

paved the way for a programme of

tailor-made operator and management

training sessions that are designed to

ensure that the product’s potential is

used to the full.

Operating experience from

the German coal industry

When operating coal faces at deep

levels, a large degree of mining

experience is needed in order to manage

geological factors, such as rock pressure

and methane emissions, as safely as

possible.

The following examples are taken

from Zollverein 1/2 seam at

RAG’s Prosper-Haniel coal mine in

Bottrop. This gassy seam is located at a

depth of 1200 m and has an average

thickness of 3.65 m.

As well as the high convergence rates

that were predicted in the gate roads

and the large quantities of dirt produced

from the face, the main challenges facing

the mine management were the high

in-seammethane content and its impact

on face operations. Figure 6 shows the

relationship between desorbable gas

content and panel layout.

In order to minimise any future

disruption to the winning process, a

large number of preliminary gas

drainage holes had to be drilled during

the roadway drivage phase. The stress

that this caused to the seam negatively

affected the stability of the coal face and

posed an additional risk for the face

team. Given the conditions as described,

coal production had to be maintained

under the threat of gas outbursts and

this meant being able to steer the shearer

without any visual contact with the

machine.

The intelligent face automation

systemwas developed for working

Zollverein 1/2 seam and, given the

danger presented by potential gas

outbursts, was designed to enable the

on-face operator to remain at a safe

distance from the machine when cutting

coal. Due to the lack of visibility at such

a distance, it is not safe for the operator

to steer the machine by remote control.

Therefore, it is vital that the shearer

can be operated without visual contact

Figure 3. Visualisation of the face situation.

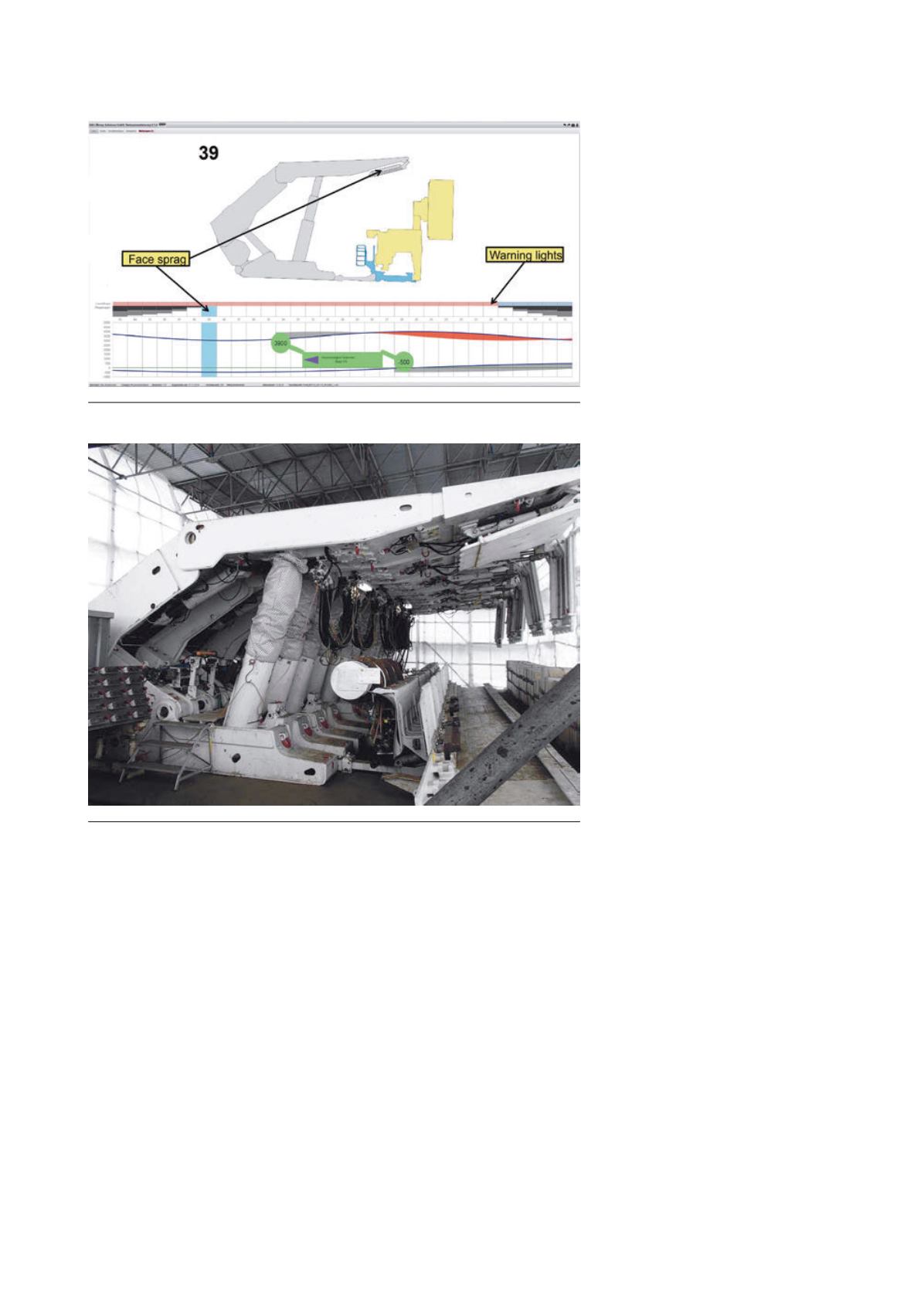

Figure 4. Testing and training set-up.

70

|

World Coal

|

August 2015