As cleat density increases, it is

generally accepted that the overall

competency of the coal decreases.

With everything else being equal, it is

reasonable to assume that the

likelihood of buckling will increase as

cleat spacing decreases, as this would

directly impact the thickness of the

column in Euler’s buckling theory. It

is however important to note that a

statistical analyses carried out by

Colwell concluded that cleat spacing

and cleat density did not have a

significant impact on rib behaviour.

6

The author indicated that this

conclusion was probably related to

the overall strength of the coal, which

appeared to be driven by cleat

density. This therefore suggests that

the average strength of a coal seam

and cleat density are related.

Primary roof support

database

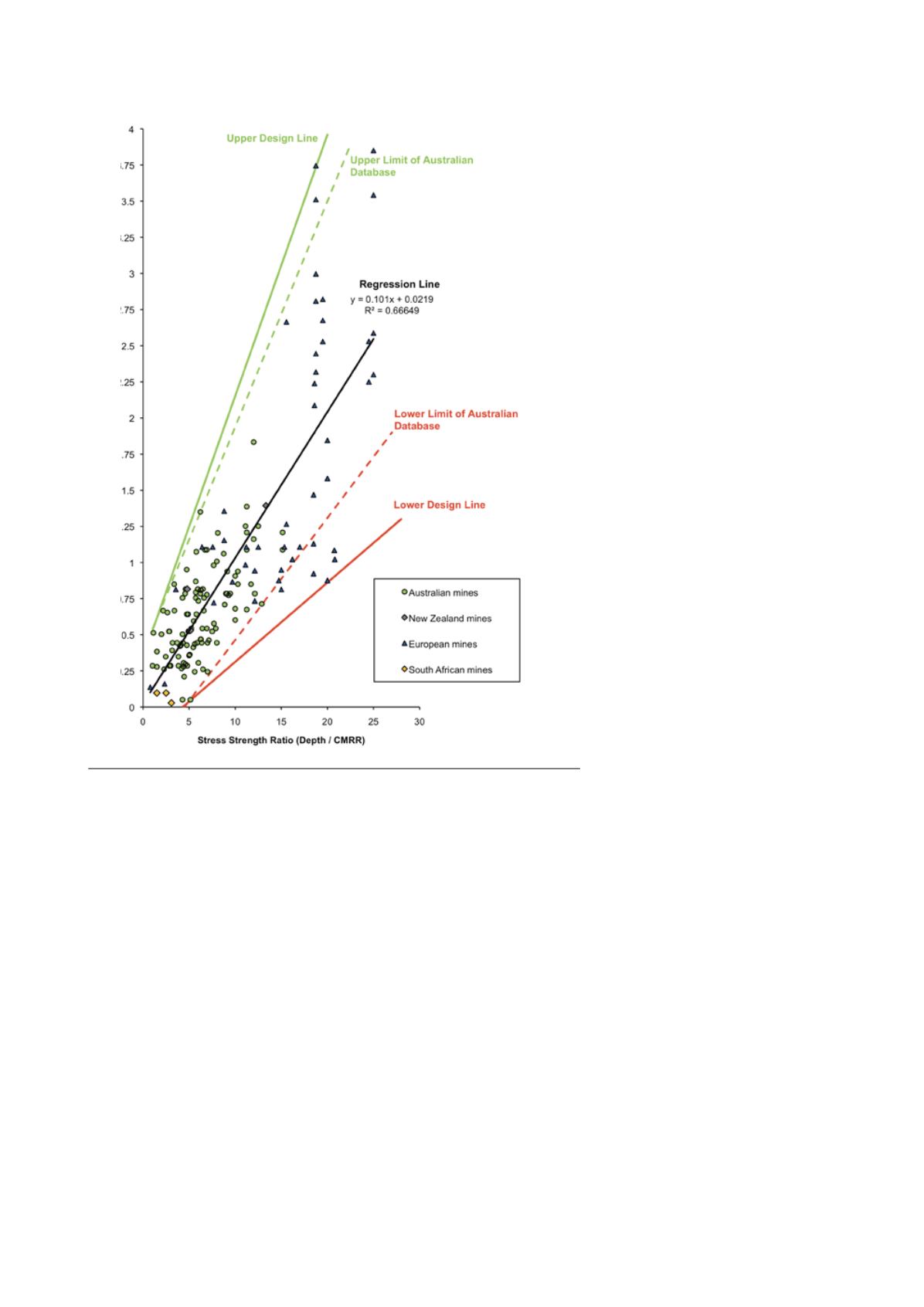

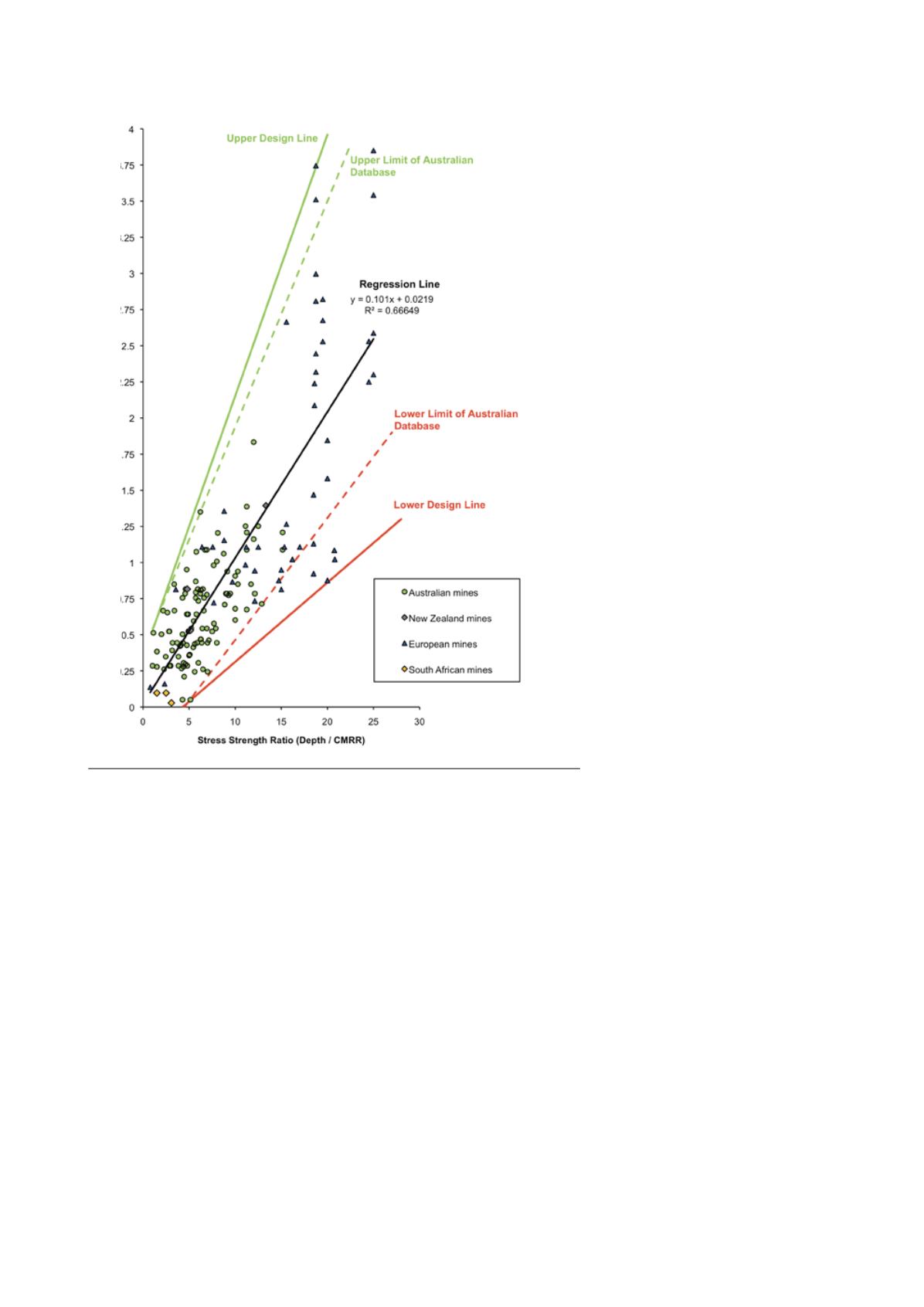

Golder’s Primary Roof Support

Database is developed from

successful primary roof support

designs installed in over 60 mines in

Australia, New Zealand, the UK,

South Africa and Norway (Figure 5).

The mines included in the world

database use similar ground control

methodologies where systematic roof

bolting is utilised.

Analysis of the data indicates that

the major factors influencing

successful roof support designs are

roof competency, which is expressed

as the Coal Mine Roof Rating

(CMRR), and the

in situ

stress. As

roof displacement is essentially a

function of horizontal stress and roof

competency, in order to provide some

form of measure as to the likely

magnitude of roof deformation

during roadway development, the

depth of cover is divided by the

CMRR to arrive at a Stress Strength

Ratio (SSR).

As shown in Figure 5, the primary

Reinforcement Density Index (PRDI)

is captured on the vertical axis. The

PRDI is a measure of the support

capacity and is reported in

meganewtons per metre (MN/m) of

roadway. The inputs into the PRDI

include the axial capacity of the roof

bolt, number of bolts per row and

row spacing, length of installed

bol and roadway width. The PDRIs

in the database range from

0.03 – 3.75 MN/m.

The roadway’s SSR is shown on

the horizontal axis (Figure 5). The

SSR’s in the database range between

0.8 – 25. Depending on the roadway’s

angle of intersection with the major

horizontal stress, a SSR of <5 is often

associated with good roof conditions,

>5 – 11 good to moderate roof

conditions, >11 – 20 moderate to poor

roof conditions and >20 poor to very

poor roof conditions.

The database indicates that as the

roof’s SSR increases, higher densities

of primary roof support are required

to adequately support the roof. This

simply means that a high stressed

and/or weak competency roof

requires more reinforcement to

control buckling, whereas, a low

stressed roof and/or competent roof

does not need to be supported with

large densities of support.

It is possible to define a Regression

Line, as well as a Lower and an

Upper Design Line. The R-squared of

the Regression Line is 0.66, which is

considered to be a reasonable fit to

the dataset. The Lower and Upper

Limit lines shown in Figure 5

effectively delineate the lower and

upper bounds of the Australian

database. Unless there is site

precedent and depending on the

region of the mine in question, these

boundaries are generally used to

define the recommended minimum

and maximum roof support

standards. It should be noted that the

database makes no specific reference

Figure 5. Golder's Primary Roof Support Database.

86

|

World Coal

|

August 2015