abutments for the next beam so each

layer above the roof has, in effect, a

progressively smaller span.

Continued failure of the beams

eventually produces a stable,

trapezoidal opening.

3

This process is

illustrated in Figure 2.

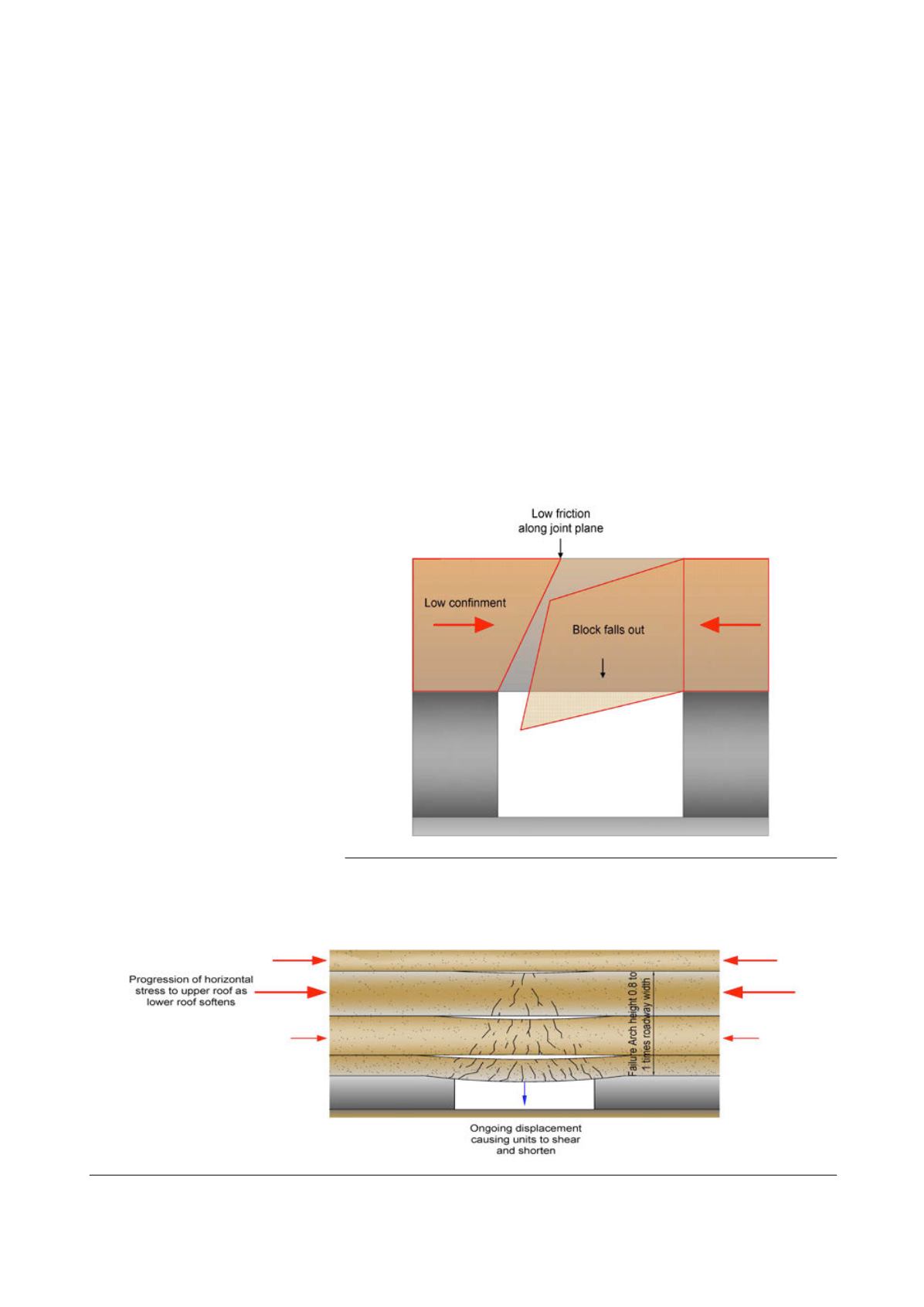

Bending failures are typically

related to beams, which are

considered continuous structures that

carry overlying weight. In most coal

mine roofs, however, the strata is

jointed and made up of individual

blocks. When these blocks are

subjected to low confinement, they are

susceptible to sliding along joint

planes, which are typically

characterised by low frictional

properties. This process is illustrated

in Figure 3.

Buckling failure

In classical beam theory, buckling can

be defined as a mode of failure

generally resulting from structural

instability due to compressive action

on the beam. As most roofs in coal

mines comprise sedimentary‑layered

rock, the individual layers of the strata

can be susceptible to buckling along

bedding planes under the action of

horizontal stress. When considering

Euler’s buckling beam theory, the

likelihood of buckling occurring

during roadway development in coal

mines is a function of unit thickness,

horizontal stress magnitude,

competency of the strata and the

elastic modulus of the rock.

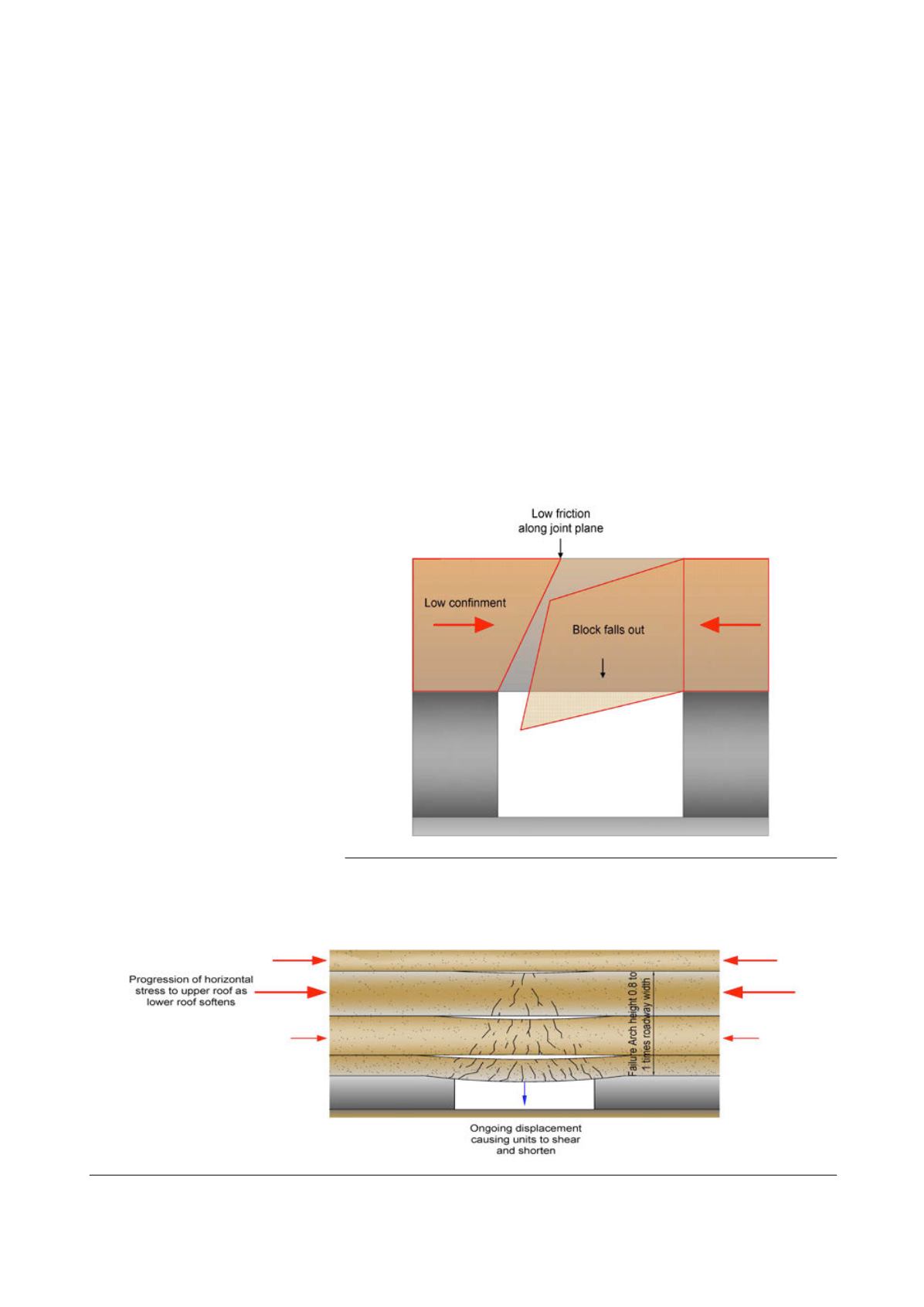

During buckling of the roof strata,

the increased amounts of

displacement will cause the units in

the lower roof to shear and thus

shorten. As a result of the stiff nature

of the loading system, the horizontal

stress and associated confinement

reduces during this shortening

process. The horizontal stress will

then transfer to the overlying stiffer,

intact beams, which are still confined

by the

in situ

horizontal stress. If not

controlled, this process can repeat

itself up to a maximum height that is

determined by the roadways failure

arch (Figure 4). The maximum height

typically assumed for failure arches

in coal measure strata is 0.8 – 1 times

the roadway width. The resulting

breakdown or ‘softening’ of the roof

and associated loss of confinement

increases the likelihood that the roof

will fall if not controlled.

Ribs

Most researchers agree that the

failure mechanism for coal ribs is

related to buckling columns.

4,5,6

When considering Euler’s buckling

column theory, the main factors to

consider are depth of cover, the

height of the rib, the thickness of the

column and the strength of the coal.

Additional factors to consider are

cleat orientation, cleat density and

prominent banding in the coal. It is a

common occurrence in coal ribs that

buckling can initiate at the interface

between the stone bands and coal due

to slipping along low friction layers.

Figure 3. Schematic showing block type roof failure.

Figure 4. Schematic showing height of failure arches above roadways.

August 2015

|

World Coal

|

85