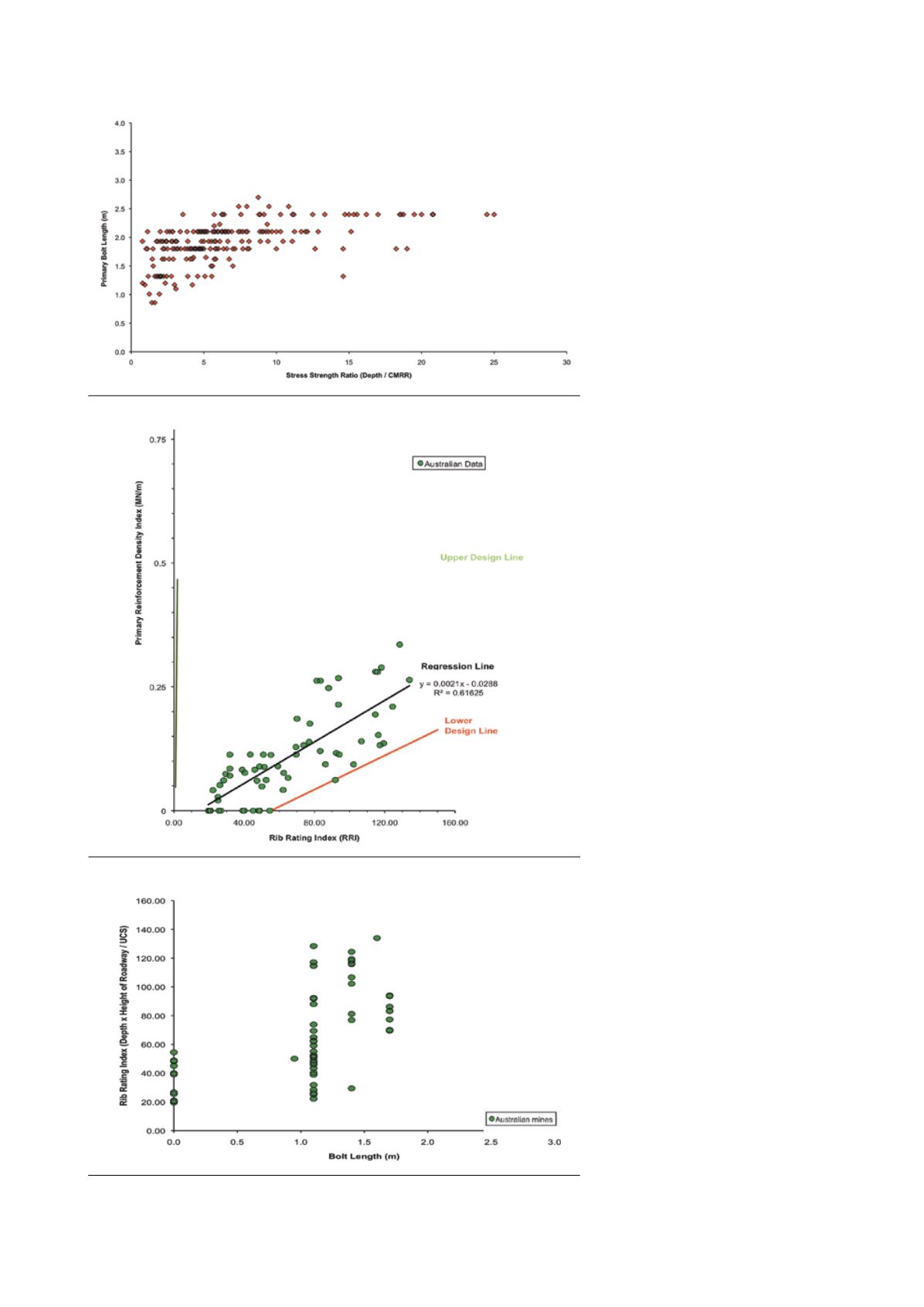

coal regions, roof bolt lengths of

between 1.8 and 2.4 m are typically

installed. This trend is almost

certainly related to the likelihood of

increased levels of roof displacement

progressing higher into the roof at

these SSRs. Although the database

indicates that these bolts lengths are

sometimes installed below SSRs of

10, the general trend shown in Figure

8 indicates that shorter bolts are

installed at lower SSRs.

Primary rib support

database

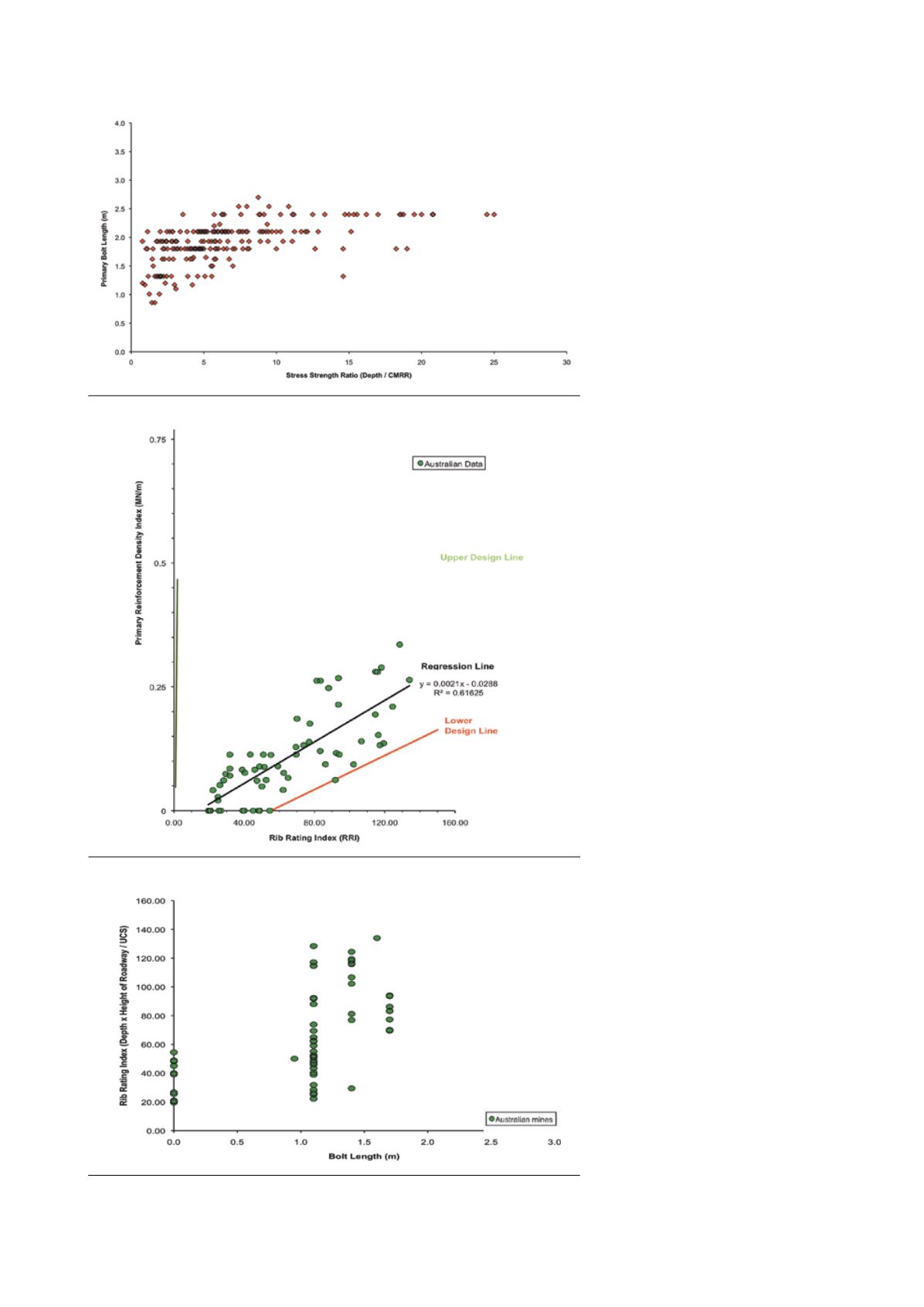

Accepting that the main failure

mechanism for coal ribs is buckling

columns, the main parameters in the

database are depth of cover, roadway

height and average

in situ

coal

strength. The depths in the database

range of 100 – 595 m and the

roadway heights range between

2.4 and 5.5 m in the Australian data.

In order to arrive at a

representable average coal strength

for each coal seam in the database,

use was made of geophysical data.

The average coal strength was

determined using a Sonic derived

UCS from site-specific geophysical

data. McNally

indicates that for coal,

the relationship between sonic transit

time (t) and UCS can be expressed

using the following equation:

8

UCS = 250000

e-0.076t.

Using this equation, it was

determined that the average

in situ

UCS of the coal seams in the

database ranges between

4.6 and 45.4 MPa.

In order to determine the likely

magnitude of rib deformation during

roadway development, the above

factors are combined to form the Rib

Rating Index (RRI) using the

following equation:

RRI = (H x R

h

) / S

n

n

H = depth of cover (m).

n

n

R

h

= roadway height (m).

n

n

S = average coal strength (MPa).

As shown along the horizontal

axis in Figure 9, the RRIs for the

Figure 9. Golder's Primary Rib Support database for Australian mines.

Figure 10. Golder's Primary Rib Support database showing bolt length in Australian mines.

Figure 8. Golder's Primary Roof Support Database showing bolt length.

88

|

World Coal

|

August 2015