while, at the same time, avoiding the

risk of collision.

Opportunities for the

international coal industry

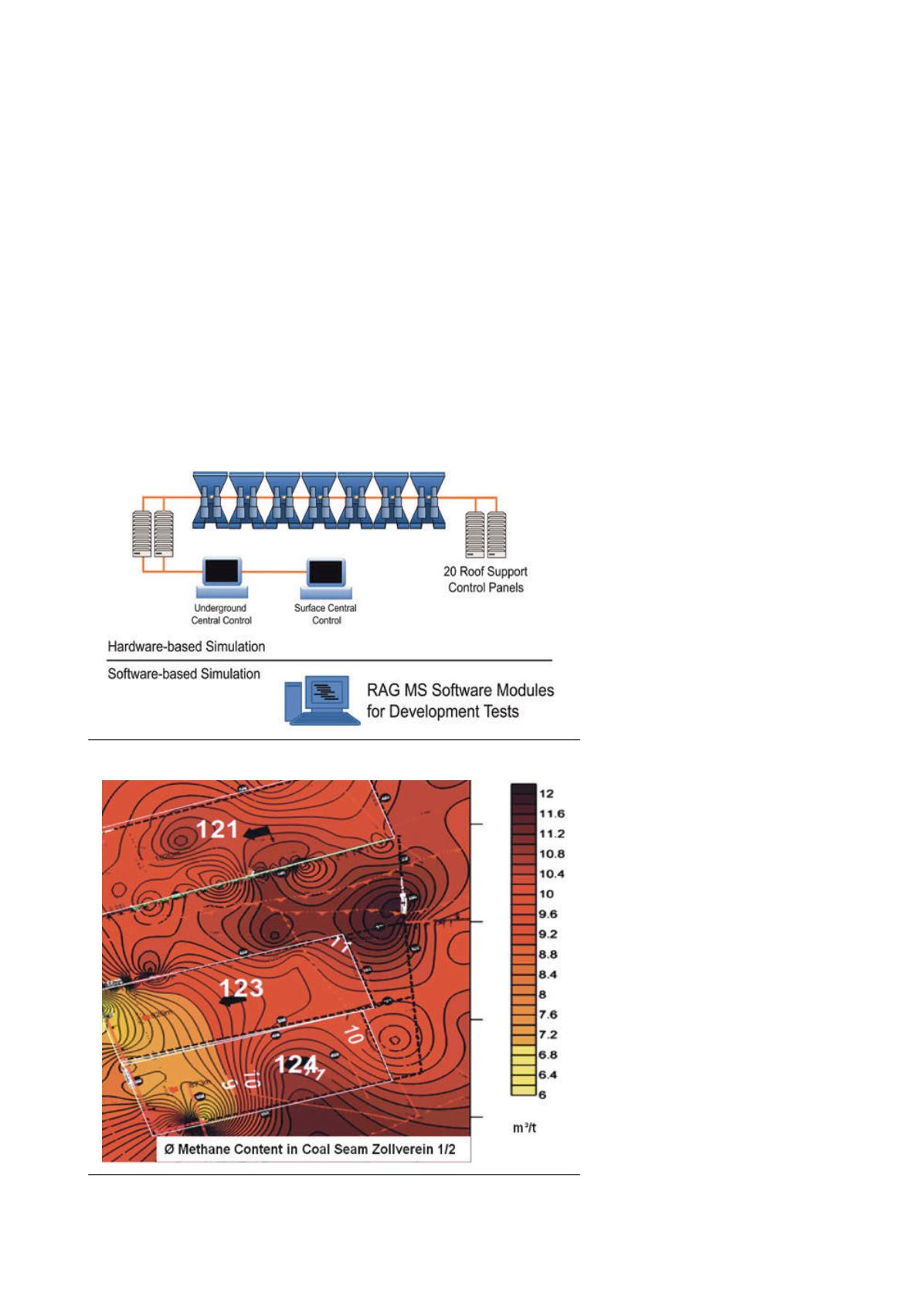

The example from the Zollverein 1/2

panel described a longwall coal face that

is prone to gas outbursts. The

technology that has been developed

here also provides an opportunity for

the process optimisation of

high‑performance coal faces around

the world.

The following arrangements must be

put in place before introducing an

intelligent face automation system:

n

n

Coordination of requirements.

n

n

Concept development and detail

planning.

n

n

Planning and equipping of the

operating space.

n

n

Organisation (tasks and

responsibilities).

n

n

Adaptation of the visualisation tools

for use above and below ground.

n

n

Technical acceptance onsite.

n

n

Training of management, operating

personnel, control room operators

and other staff.

n

n

Technical support during

commissioning.

n

n

Incorporation into an ERP

(enterprise-resource-planning)

system, if required by the

client‑operator.

Throughout the entire process, the

mine operator will therefore be able

to take advantage of the

operating experience, development

efforts and training expertise of

RAG Mining Solutions.

On the basis of these preparatory

arrangements, the coal mine will be

able to manage the coal production

process in line with the latest

technology and derive all of the benefits

that result from it, such as:

n

n

A high level of operating

reliability.

n

n

Efficient use of all machines and

equipment.

n

n

Coordinated manpower

deployment.

n

n

Operational monitoring based on

the visualisation of all information

that is relevant for the control

station.

n

n

Modular mine control system with

interfaces that are matched to the

operator network.

n

n

Process analysis based on the

provision of data in an ERP system

(optional).

Integration into an existing control

room system calls for defined

interfaces and a stable data connection

between the underground workings

and the mine surface. The modular

design of the system makes it a

suitable performance upgrade for

production faces at coal mines that

already operate control room

technology.

Additional modules can also be

installed to expand the application

options. These can easily be integrated

in order to optimise the overall coal

mine operations on a step-by-step

basis. Alternatively, and especially in

the case of greenfield projects, the

entire package of modules developed

for the RAG Mining Solutions

self-sustaining control room

technology, including the intelligent

face automation system, can also be

installed on a total-system basis.

This allows a mine control room to

be set up without having to use

external software modules. The

specific benefits of this option are

discussed below.

Figure 6. Relationship between desorbable gas content and panel layout.

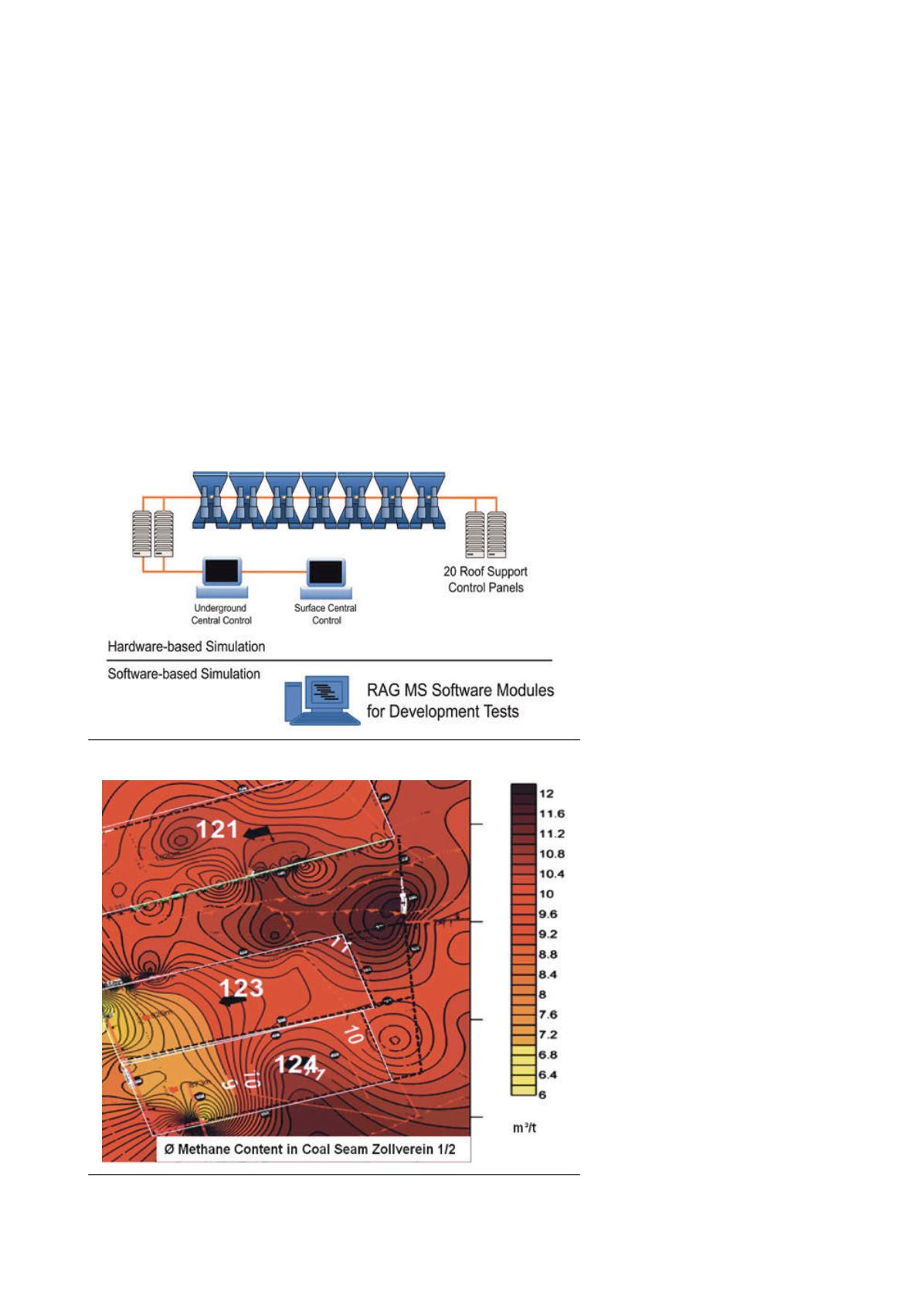

Figure 5. General view of the surface test face.

72

|

World Coal

|

August 2015