Rig control system

The automation platform for

Atlas Copco blasthole drilling

equipment is the rig control system

(RCS), which is based on standard

PC-computer technology. The new

generation of RCS rigs has taken a

quantum leap forward with respect to

logging capabilities, serviceability and

drilling accuracy. CANbus technology

provides the backbone of this new rig

control system. It is flexible and easily

expandable, allowing new units to be

added anywhere along the data bus by

cable.

The electronic modules are all

developed solely for the RCS rigs and

are ruggedised and protected from

external magnetic and electric

influences. For surface blasthole

machines, the flexibility of the system is

highly utilised and can be adapted and

configured for a variety of product

types. Customers can start at a low-level

of automation and, as their requirements

change, can upgrade. New functionality

can be added without major rebuilding

of the machines.

Safety features

The RCS Basic provides the machine

with additional standard interlocks,

compared to the electric‑over‑hydraulic

machines. A few of the interlocks created

with the software are:

n

n

Hole depth indicator: displays the

rotary head position, as well as the

depth of the hole drilled.

n

n

Pipe in hole tram interlock: rotary

head must be in a safe position to

allow tramming.

n

n

Jack interlock: pipe in the hole will

disable jack functions to protect the

machine and reduce bending of

rods.

n

n

Rod support interlock: prevents

damage of the rotary head and rod

support by not allowing feed with

rod support to be in the stowed

position.

n

n

Carousel no-bump: prevents

damage to the carousel by limiting

pulldown pressure when the

carousel is not in the stowed

position.

n

n

Breakout wrench protection:

prevents damage to the breakout

wrench by disabling pulldown

when the wrench is not in the

stowed position.

n

n

Engine and electric motor

information displayed over the

touch screen maintenance screens.

n

n

Low fuel, lube and water level

messages.

n

n

Tram interlocks, so a trigger must be

activated to allow tram function.

GPS hole navigation

To ensure the blasthole is precisely

positioned to where the mine engineer

has designed the blast pattern and is

drilled to the correct depth, GPS hole

navigation has been developed for the

RCS platform. This hole navigation

system uses antennae mounted on the

tower rest and radio antennaa on the

cab to produce an accurate bit position.

Drill plans designed with the local mine

coordinates are imported into the

system and the bit position is provided

in real time. The bit position is precise

and is calculated by taking into

consideration the variability on the

bench, providing the operator with the

correct depth to drill each specific hole.

This feature also provides a moving

map display with zoom functions as

the rig is trammed closer to the desired

blasthole location. The dominant

system for positioning of a rotary drill

on a blasthole drill plan is with satellite

navigation based on GPS or GPS and

Glonass.

It is possible to reach accuracies of up

to ±10 cm, depending on installation and

the number of available satellites. The

integration of the GPS receiver to the

control system is done via a standard RS

serial link. The preferred protocol to use

is the standardised NMEA0183. The

advantage of having the GPS system as

a positioning sensor enables customers

to choose products of any brand

(Trimble, Leica, Topcon), depending on

the preferred standard in the actual

mine.

Rig remote access and

communication

The rig remote access (RRA) system

fromAtlas Copco gives a customer the

ability to connect the drill rigs to a

standard computer network on a

worksite. The RRA system allows

access to information on the drill rigs

from any authorised point in a network.

The RRA system basically consists of a

communication server onboard the drill

rig and a network adapter. The server

supplies the user with three functions: a

web server that can connect to any

standard web browser, an FTP server to

enable transferring of data (files) to and

from the drill rig and a server process

that enables any data to be integrated

into the user’s administrative systems.

If a commercially available ‘office’

network is used on the worksite, which

is easy to install into the existing

infrastructure, it restricts the RRA

functionality to only remote access and

does not permit remote control.

Standard communication equipment is

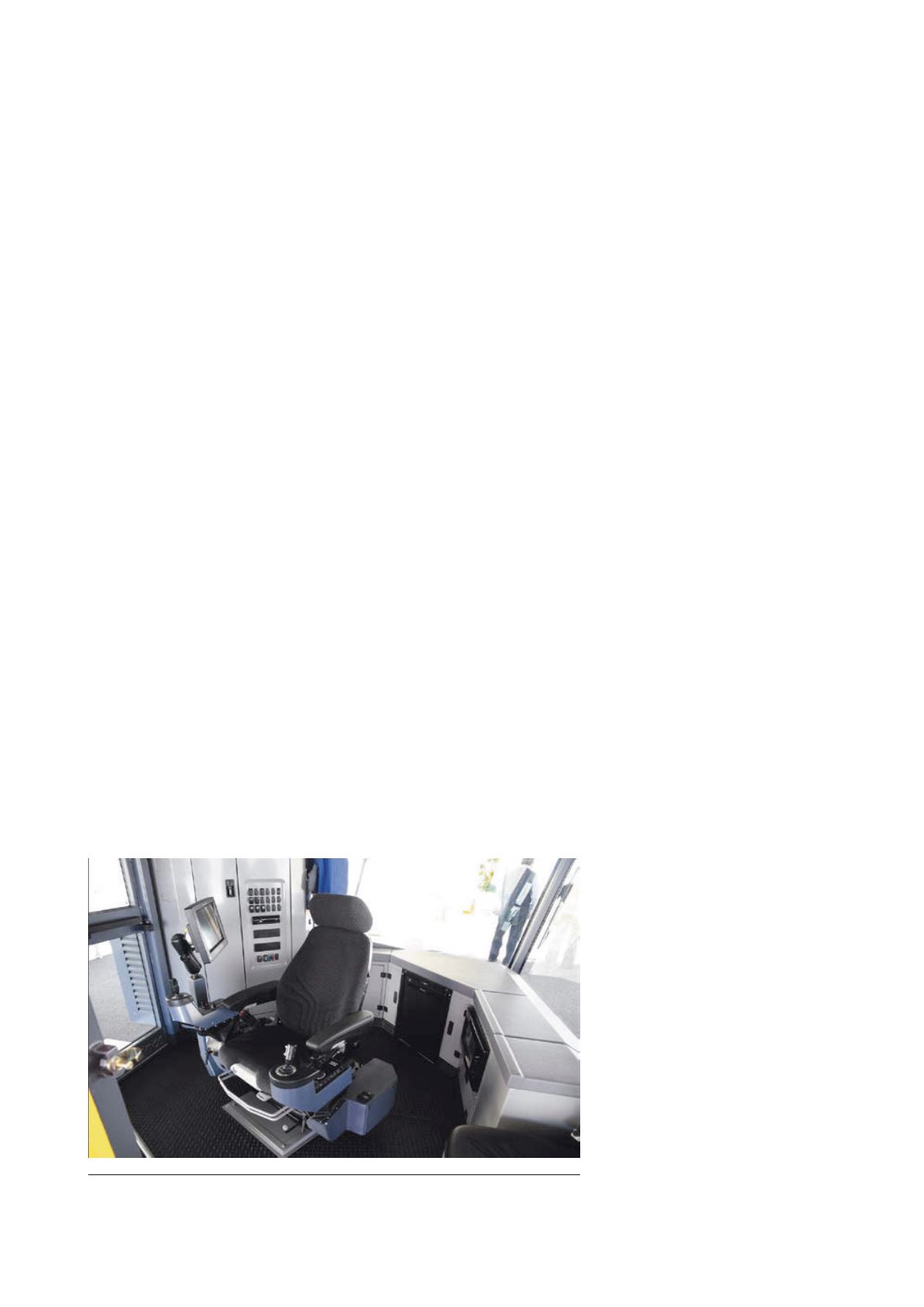

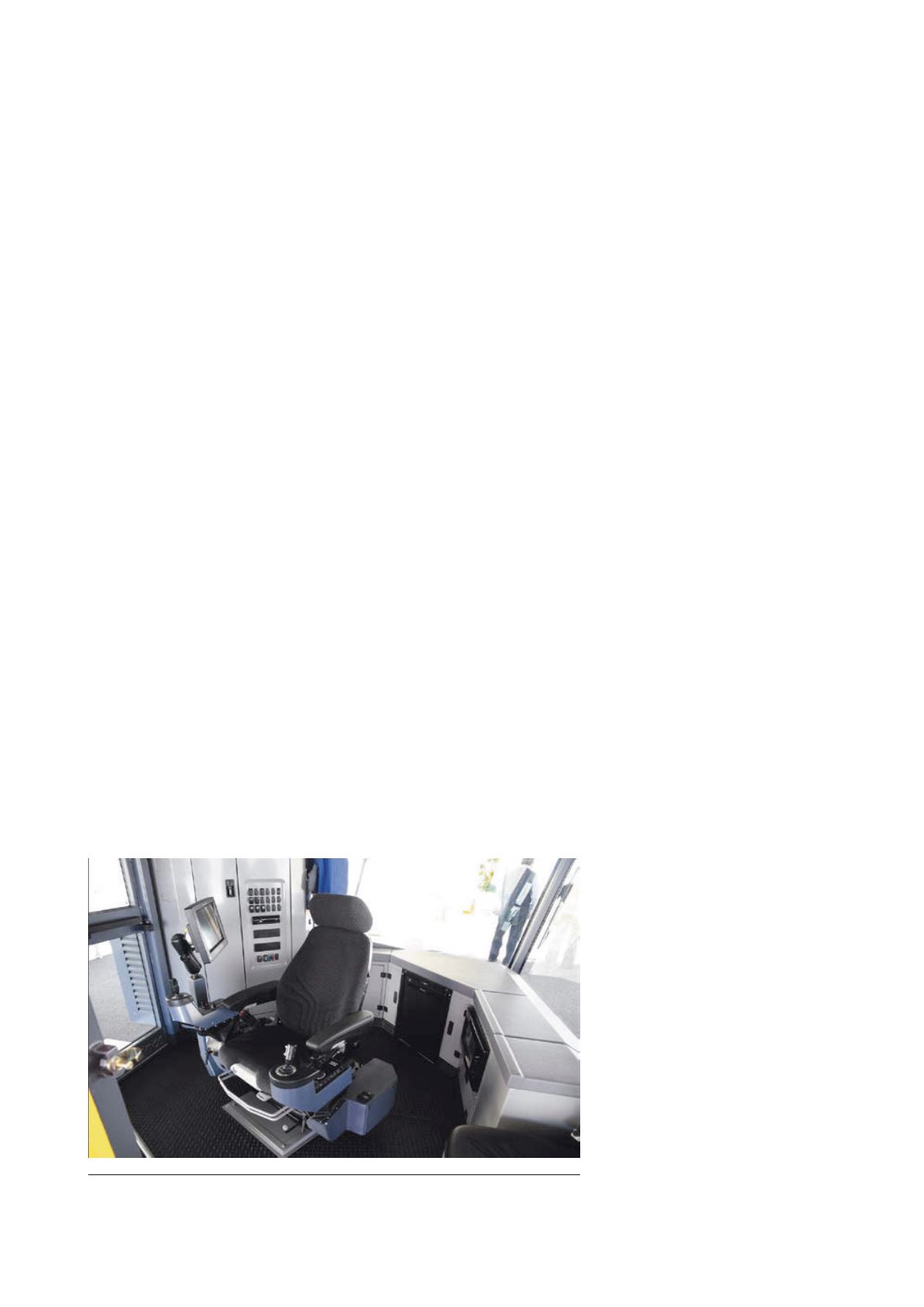

RCS cabin on a PV-310 series.

96

|

World Coal

|

August 2015