China, it is the actual capacity of theAFC

that mostly affects the final production.

While the maximum capacity of theAFC

has reached 4500 tph, the actual efficiency

is, on average, only 17%. Even in large

coal mines, an efficiency of only 35% is

hardly satisfying. ABB found that high

maintenance rates and unstable loads are

the main reasons for low efficiency.

New AFC starting method

As mentioned before, VFDs are capable

of large starting torque. This reduces the

risk of unsuccessful starts and saves

man-hours for clearance of overload coal

on the AFC when starting.

AFCs normally have one motor for

the head drum and one for the tail

drum. Before starting, spare chains are

stacked under the head drum and this

creates the potential risk that they will

block the return way underneath. Using

the tail drum to tension the return chain

first and then starting the two drums

together will prevent this risk, while

accomplishing an efficient start.

Compared to the current practice of

running the tail drum for 1 – 7 sec. in

advance, this control idea will detect the

pre-running time automatically and run

the two drums together. It can make sure

that the two drums both contribute via

the tensioned return chain during the

starting.

New balance method to reduce the

wear of tail area

Optimised power distribution can be

easily achieved based on VFD with

DTC technology. The head drum

controls the speed of the whole AFC

and the tail drum tensions the return

chain first and contributes in heavy

load. To optimise performance, a

dynamic adjustment between head

drum and tail drum, also known as the

‘new balance method’, is completed

during operation.

Comparing to 1:1 power

distribution, the new balance method

has advantages both in light and heavy

load situations.

In light loads, the tail drum can get

more power for return chain tension to

avoid stack risk. Tensioning of the return

chain also means that the spare chain

loosens the chain on the top in the tail

area, which will lower the pressure of

the chain against the upper armor plate

and thus reduces wearing (Figure 4).

In heavy loads, the tail drum should

be precisely controlled to make a

contribution to the load, while avoiding

too much tension power frommaking the

release of the chain from the head drum

difficult.

Dynamic chain tension adjustment

system

Deformation of the chain is happening

all the time and a loose chain will cause

unstable running of the AFC and

increase the stack risk. In traditional coal

mines, there is a tension pump for the

chain at the tail area. An experienced

worker will tension the chain and

manually fix extension length

occasionally with a pin.

Dynamic chain tension adjustment

systems can automatically adjust the

chain according to a set pressure all the

time when working. It leaves out the

risk of human error and saves man

power underground.

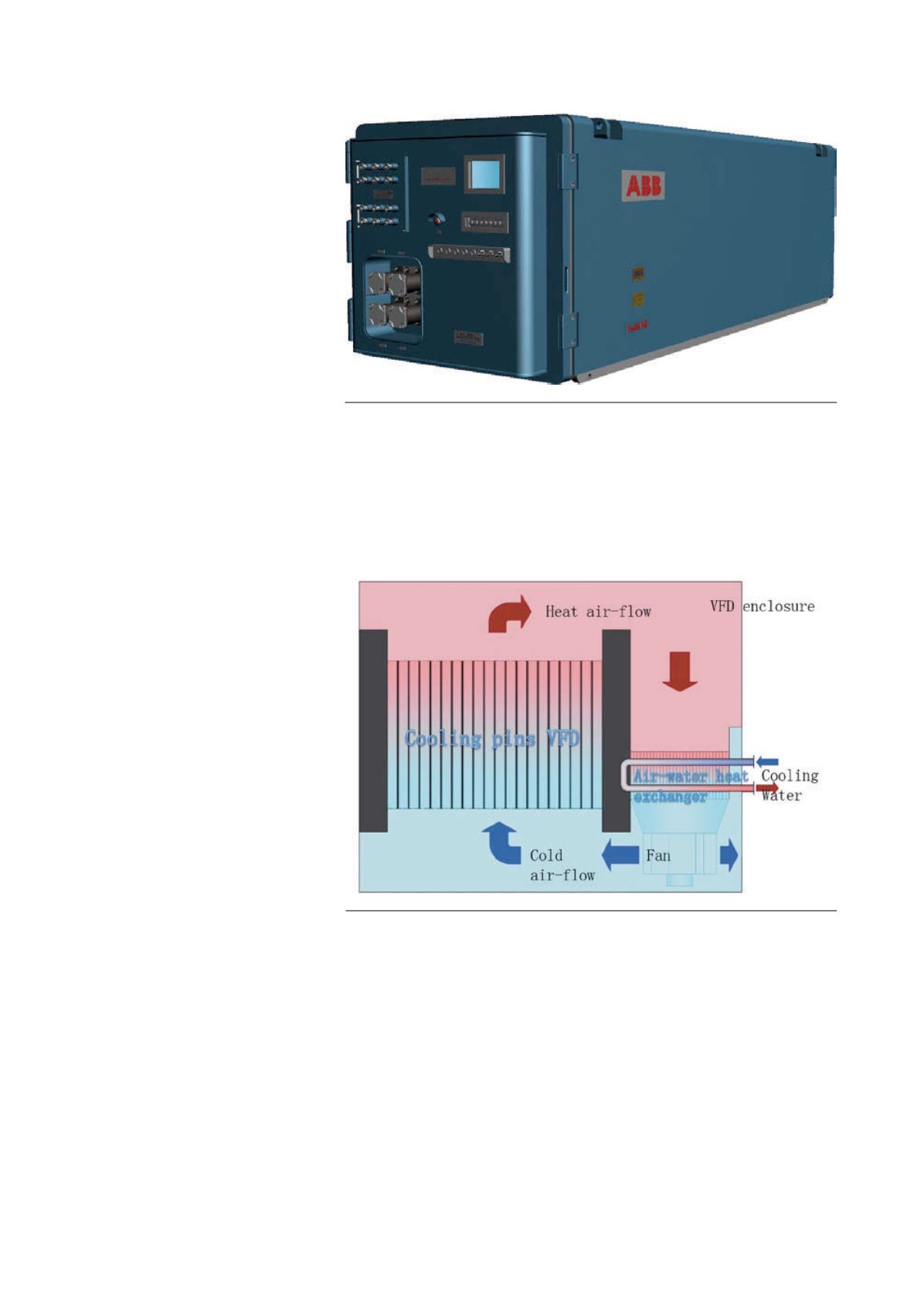

Figure 3. Air-water heat exchange system.

Figure 2. 3300V Ex-proof drive with air-water HEX method.

Type: BPJV-xxxx/3.3(xxxx: 1000 KW~2000 KW).

Nominal Voltage: 3300 V.

Overload capability: 150% 1 min./10 min.

Length of motor cable: about 2000 m.

Topology: 2-Q 12-pulse converter, voltage source 5-level inverter.

Control method: DTC.

HEX solution: Air-water HEX system.

Ex-proof type: Exd[ib] I Mb.

August 2015

|

World Coal

|

65