Smart microprocessor-based devices have been developed

by a number of leading vendors. Advanced monitoring and

control technology for ESD valves has made PSTs more effective

and easier to implement, helping to better balance the need

to achieve higher pipeline integrity and safety. This includes

considerations, such as spurious trip rate, initial investment and

ongoing operational costs, system integration and documentation

requirements.

Today’s intelligent valve monitoring and automation solutions

allow pipeline operators to achieve high SIL levels while delivering

a greater diagnostic coverage factor, flexibility in implementing

and scheduling PSTs and improved communications. There are a

number of popular methods for partially stroking valves, and each

has its advantages and disadvantages.

The most common techniques include:

)

)

Mechanical jammers.

)

)

Digital valve controllers (smart positioners).

)

)

Digital control transmitters.

Mechanical jammers are the simplest and least costly

option for automated local or remote PST functions, but they

involve a manual process. These devices are used in cases where

accidentally shutting the valve would have severe consequences

or any application where the end user prefers a mechanical

solution. The jammer is integrated in the design and is intended

to limit valve movement, linear or rotary when placed in position

with a key. There is a major disadvantage with mechanical

jammers if an ESD event occurs during the PST test interval. The

need to manually place the jammer can also cause the valve to

move suddenly and violently. Human errors by field technicians

can also result in complete valve closure. Therefore, the reliability

of this technique is dependent on procedures, training, and

correct design specifications.

The digital valve controller (i.e. smart positioner) is the most

common and complex of the three PST options. It is designed to

generate an automatic PST function via an internal IP transducer

and capture dynamic diagnostic data of the test. However, the

positioner does not capture the ESD event, thus requiring the

use of additional devices, such as limit switches or position

transmitters. Also designed for automated local or remote PST,

the positioner-based approach is a proportional control style of

valve movement. It is created by the ESD system step changing

the positioner’s set point value to the PST target value. The device

monitors the speed and quality of response as well as actual valve

position. If the valve does not respond within a reasonable period

of time, the positioner’s microprocessor cancels the test.

The latest entry into the automated PST market is the digital

control transmitter. It is specifically designed to capture the ESD

event and functionally test solenoid valves (SOV). The device

generates an automatic PST function by temporarily de-energising

the ESD solenoid valve and captures dynamic diagnostic data

of the event. This low power, SOV-based solution is suitable for

both low and high pressure pneumatic and hydraulic applications.

Compatible with the HART®, WirelessHART™ and FOUNDATION™

fieldbus communication protocols, today’s digital control

transmitters eliminate position blind spots during the stroke of

a valve by supplying continuous feedback of either rotary or

linear valve position. Thus, they are a cost-effective alternative to

positioners for SIS applications requiring service up to SIL3.

The digital control transmitter is essentially a position

transmitter with a solid-state relay, which the SIS logic solver goes

through and powers the ESD solenoid valve. When it receives a

partial stroke test command, it opens the normally closed solid

state relay and de-energises the ESD solenoid valve until a partial

stroke position is met. Then, the relay closes again to the standard

position, the solenoid returns to fully energised and the value

goes to 100%. Because the digital control transmitter captures

the ESD event, it is never ‘blind’ like other solutions. As with any

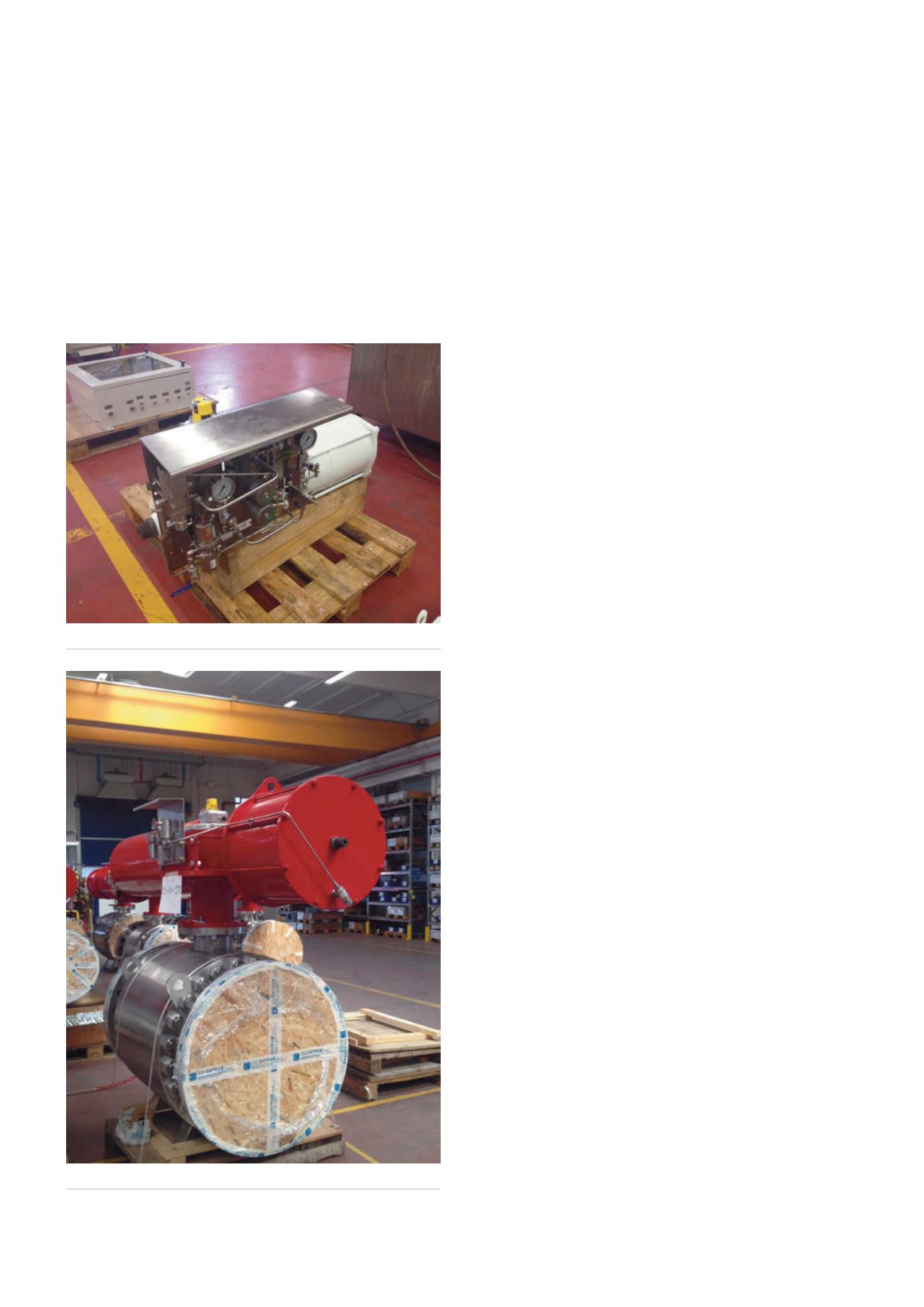

Figure 3.

Complex control manifold.

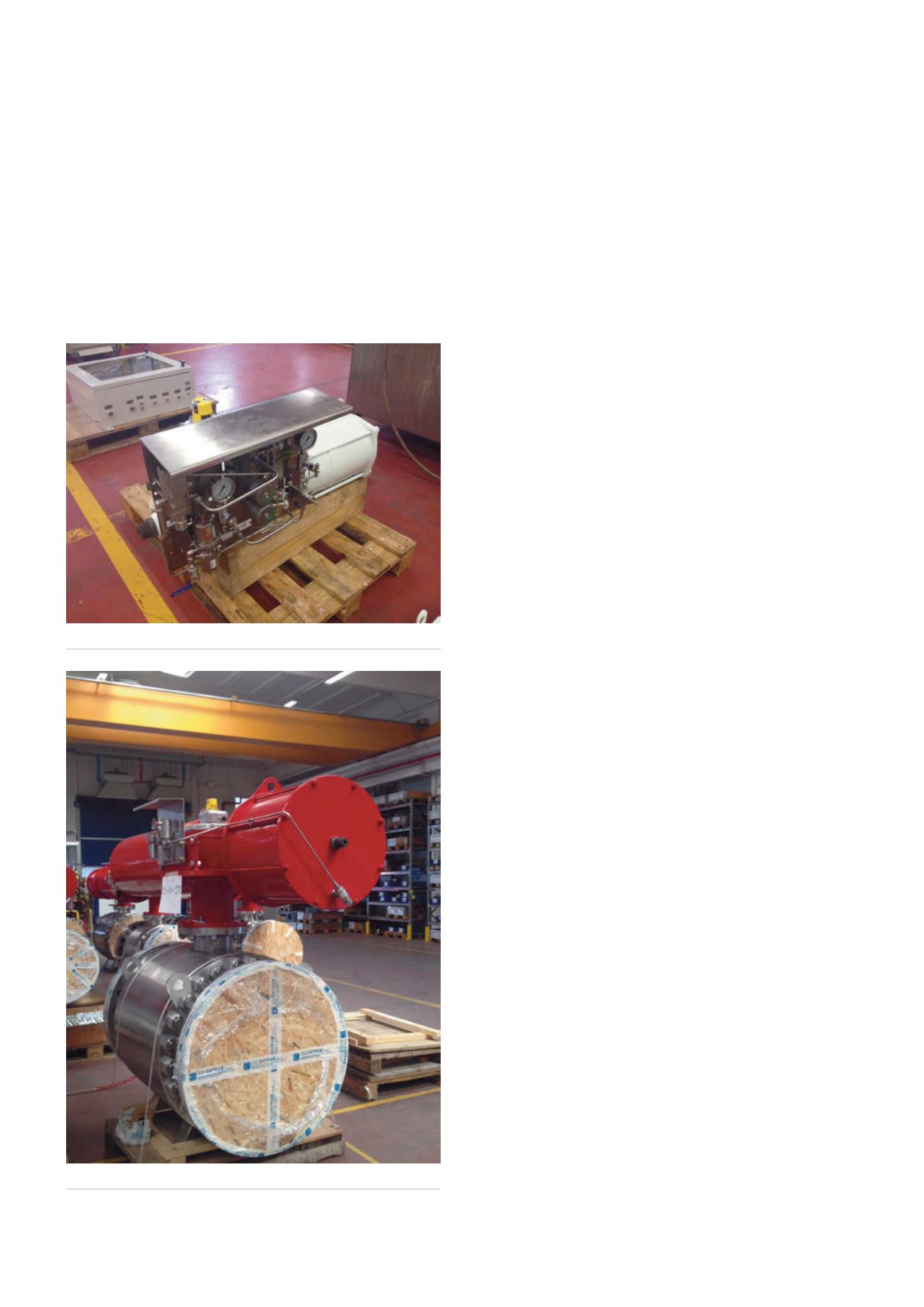

Figure 4.

Automated ball valve.

104

World Pipelines

/

JUNE 2015