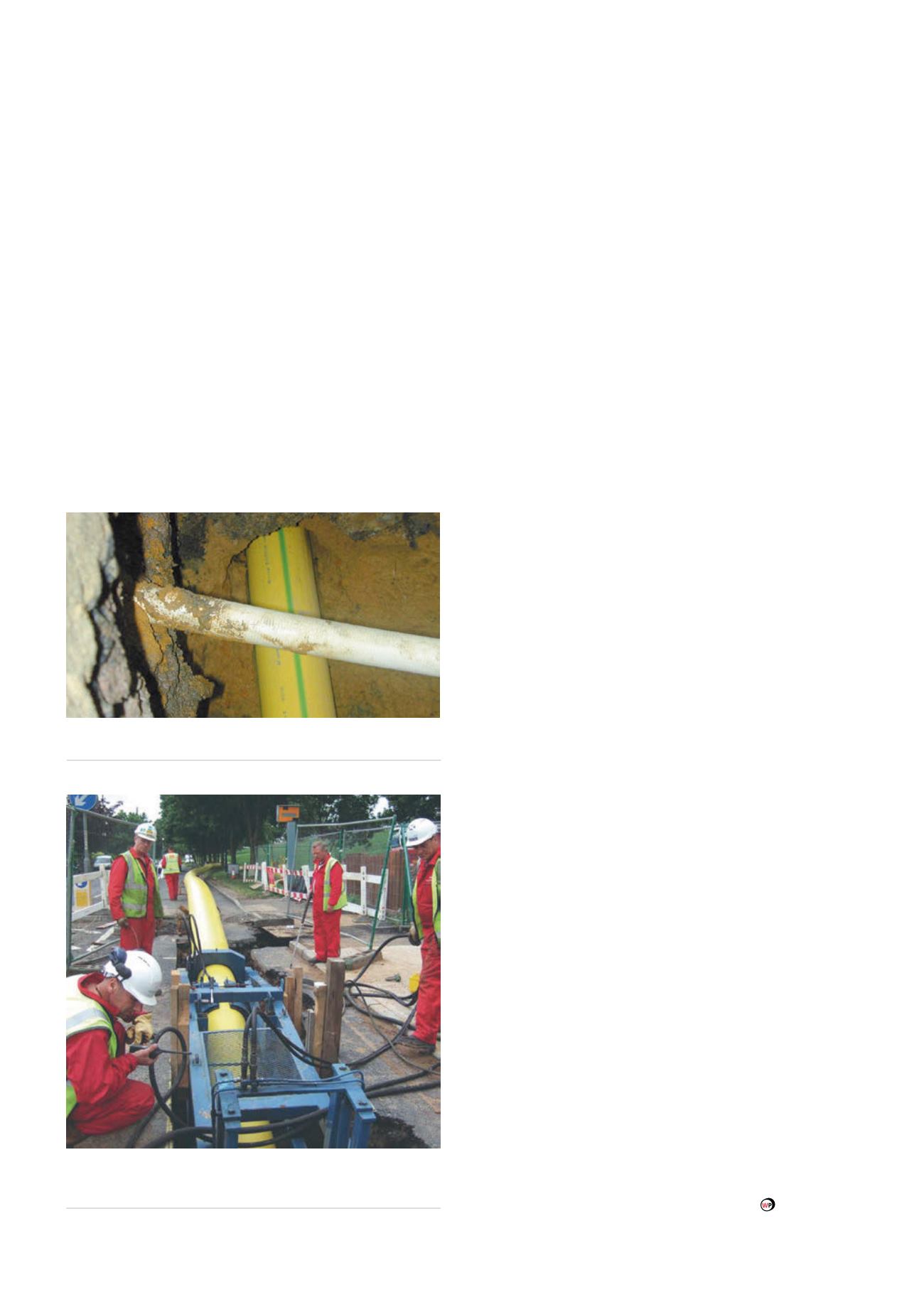

In the early morning hours, the gas main was interrupted and

the service connections were disconnected. After the necessary

preparations and subsequent machine set-up within 30 minutes,

the pushing in of the QuickLock bursting rods began. After

20 minutes, this operation was finished. It took only a few simple

movements to link together the laid out pipe string, the expander

and the bursting head with the rods. Shortly before noon, the

pulling in process was started using a GRUNDOBURST 400G

rig in the pedestrian zone of Harkort Street. Residents were not

disturbed by open trenches, noisy breaking up and other related

excavating works thus allowing for the business shops in the direct

vicinity to carry on as usual. After only 30 minutes, the new pipe

string was pulled in. The bursting rig was already removed from

site at 12:15 p.m. and the crew proceeded with the pressure test

and integration of the service connections. At 4 p.m., all of the

households were re-connected to the gas network.

Key facts:

)

)

Technique: static pipe bursting.

)

)

Equipment: GRUNDOBURST 400G.

)

)

Host pipe: Gas main, cast iron ND 100 (4 in.).

)

)

New pipe: PE with protection coating ND 100 (4 in.).

)

)

Pipe bursting length: 60 m (197 ft).

)

)

Client: Dortmunder Energie- und Wasserversorgung GmbH.

)

)

Pipe bursting contractor comapany: PAUL SPEECK GmbH,

Dortmund, Germany.

)

)

Location of job site: Dortmund-Hombruch, Germany.

)

)

Duration: one day.

)

)

Remarks: performing the job in January without the need of

temporary supply.

Close-fit lining of a gas mains using the reduction

method in the UK

National Grid is one of the world’s largest utility companies

and the biggest gas and power supplier in the UK. The so-called

reduction method has successfully been used to refurbish large

diameter medium pressure gas mains. The existing 458 mm (18 in.)

dia. cast iron main has been relined with a 469 mm SDR21 - PE80

pipe.

The usual cumbersome 40 t capacity hydraulic capstan was

replaced with a specially adapted GRUNDOBURST 800G pipe

replacement rig, fitted with the unique QuickLock ladder type

rods for fast, reliable and safe handling. Due to some of the offset

bends of the existing main, the QuickLock rod’s flexible joints easily

overcame the associated pushing and pulling side load forces.

Installation speeds were as high as 180 m in just 1 hr 35 min., but

what was equally impressive was the ease of docking the new pipe

in the specially constructed reduction dye which together with the

GRUNDOBURST’s push pull brake and fingers, ensured minimum

pipe contraction both during the installation and reversion process.

Key facts:

)

)

Technique: reduction method.

)

)

Equipment: GRUNDOBURST 800G.

)

)

Old pipe: gas main, cast iron ND 458 (18 in.).

)

)

New pipe: PE 80 SDR21, ND 469 (18.5 in.).

)

)

Pipe bursting length: 60 m (197 ft).

)

)

Client: National Grid/PMC, UK.

)

)

Pipe bursting contractor: Morrison Utility Services, UK.

)

)

Remarks: installation speed of 180 m in 1 hr 35 min.

Conclusion

The applications described show that trenchless technologies

are becoming more and more important in pipeline installation

and rehabilitation due to the sustainability of the methods. Their

share compared to open trenching is ever increasing because

the underground installation and renewal of supply pipes bears

major technical and economical advantages as excavation and

re-instatement work are almost omitted and construction times

are short and the environment is hardly impaired.

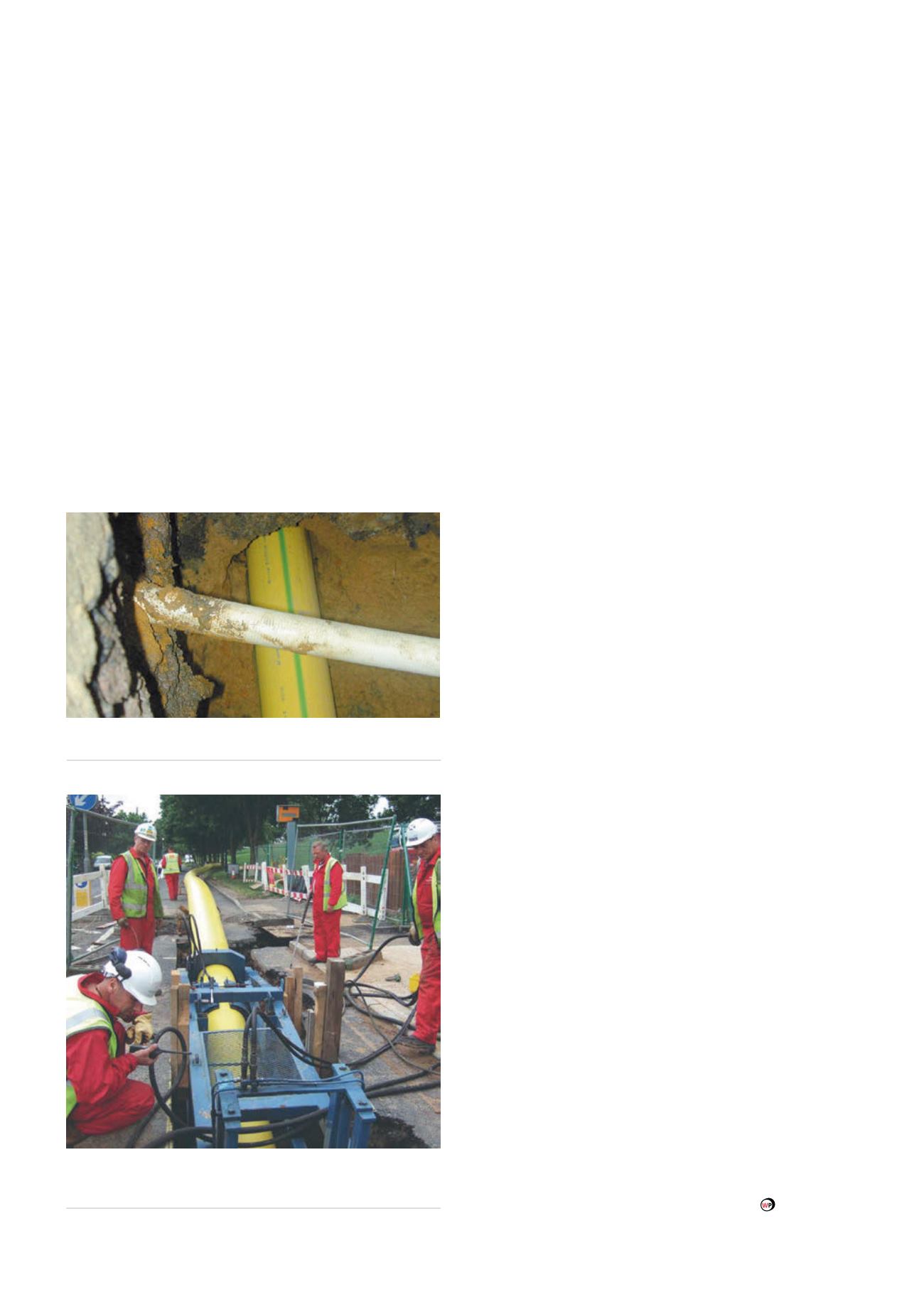

Figure 8.

The new pipe srtring is pulled through the reduction

dye being slightly reduced to fit tightly into the old pipe

afterwards.

Figure 7.

View of a pit within the area of a service connection

showing the new pipe installed without any damage.

112

World Pipelines

/

JUNE 2015