S

triving to find the best

solutions for optimising

pipeline performance and safety

while saving costs is one of the

greater challenges in the oil and gas industry.

Pipeline operators are under a variety of pressures

– from new industry standards and increased requirements

from government agencies to cost, profitability and staff reductions.

There is an increased focus on meeting new safety regulations and

preventative maintenance requirements, which have been created to

ensure continuous and accident-free operation of pipelines.

To meet these new standards and protect against hazardous events

such as leaks or pressure spikes, valve automation forms a critical part of

pipeline systems. However, these safety assets can be compromised by

the installation of incorrect equipment or inadequate maintenance.

Safety instrumented systems

Pipeline operation involves inherent risks due to the presence of

hazardous, corrosive or unstable media. Safety instrumented systems

(SIS) are specifically designed to protect the pipeline by reducing the

Understanding

Leo Minervini,

Business Director

Controls, Pentair

Actuation &

Controls,

takes

a look at how the

latest technology

is optimising safety

valve performance

and reliability.

safety

systems

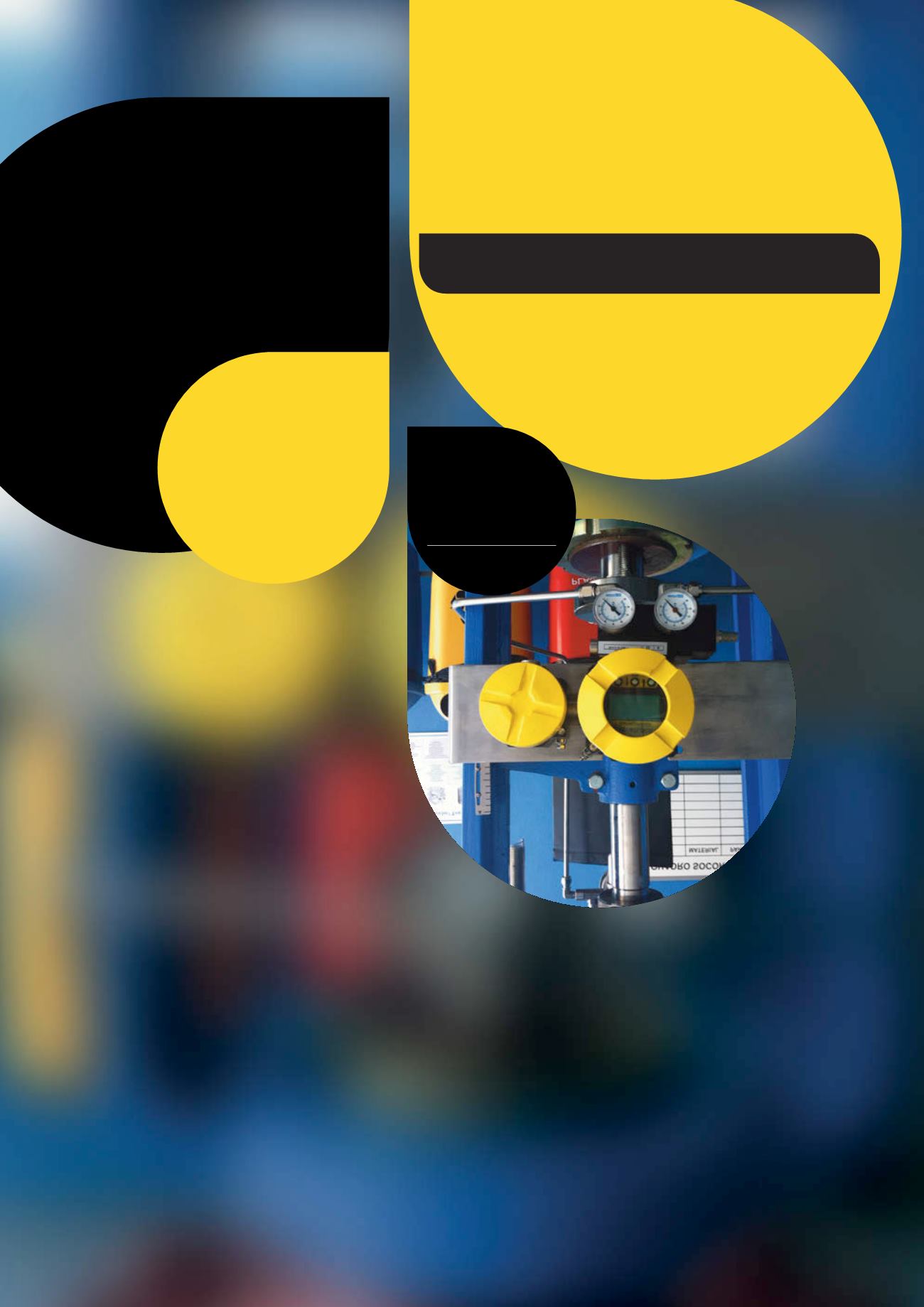

Figure 1.

Westlock

Controls’ ICoT

6000 explosion-proof

smart positioner

mounted to a Hiter

control valve.

101