contractors’

directory

2015

TURNKEY

CONSTRUCTION

72

ONSHORE

PIPELINES

REHAB

MAINTENANCE

RESEARCH &

DEVELOPMENT

TERMINALS

FEASIBILITY

STUDIES

FINANCE,

STRATEGY

& ANALYSIS

WELDING

COMPRESSOR

STATIONS

HORIZONTAL

DIRECTIONAL

DRILLING

OFFSHORE

PIPELINES

L

CS Cable Cranes offers innovative solutions for the

construction of oil and gas pipelines in steep and

inaccessible terrain. By using specialised equipment,

the Austrian company enables the laying of pipes

where it seems impossible.

Highly technological and proven cable crane systems

are applied on steep mountain ranges, on rock faces and

in the middle of the rain forest. The crane

systems work like material ropeways and are

able to transport all kinds of heavy material,

such as pipes, machinery, excavators, padding

material and sandblasting equipment, with

the highest precision along the route of the

pipeline, where it can be unloaded at any point

of the track.

LCS’s material-ropeways are capable of

carrying loads that exceed 20 t along distances

of more than 3 km and with a speed of up to

7 m/sec.

The cable crane system consists basically

of one or multiple track ropes, towers, a haul

rope, a haul winch and a crane unit. It is installed

exactly above the determined route for the

pipeline and works similar to a material-ropeway:

at the loading station loads are lifted by a

crane unit. Consequently, being attached to the

crane unit and pending on mid-air, they are pulled by the

powerful haul-winches towards the designated position,

where they are lowered and unloaded. Thanks to the

double lifting systems, pipes can be inclined and therefore

perfectly placed in their welding position. Transport

buckets are used to transport padding material – they are

unloaded easily by inclining them.

Using the cable crane systems as a method for the

laying of pipes in steep terrain gives several advantages.

A very narrow ROW reduces the environmental impact

significantly since cable cranes only require a width of 8 m

(reducible if necessary) and less access roads need to be

constructed. Consequently, even cost savings can be made

due to less re-instatement and road-construction costs.

In sometimes removing completely

the need for heavy machinery to

work on steep slopes, operators are

not exposed to risks, as all material

is transported by air to its final

destination.

The systems are applicable in all

kind of terrain; it does not matter if

routes run vertically or horizontally to

the slope, are straight or include curves.

The cranes are readily available

and flexible solutions that are based

on a modular system. Nevertheless,

an accurate project management

including analysis, planning, installation,

implementation and operation of the

crane systems by LCS professionals is

indispensable.

A crane unit of LCS is

transporting a 46 in. pipe.

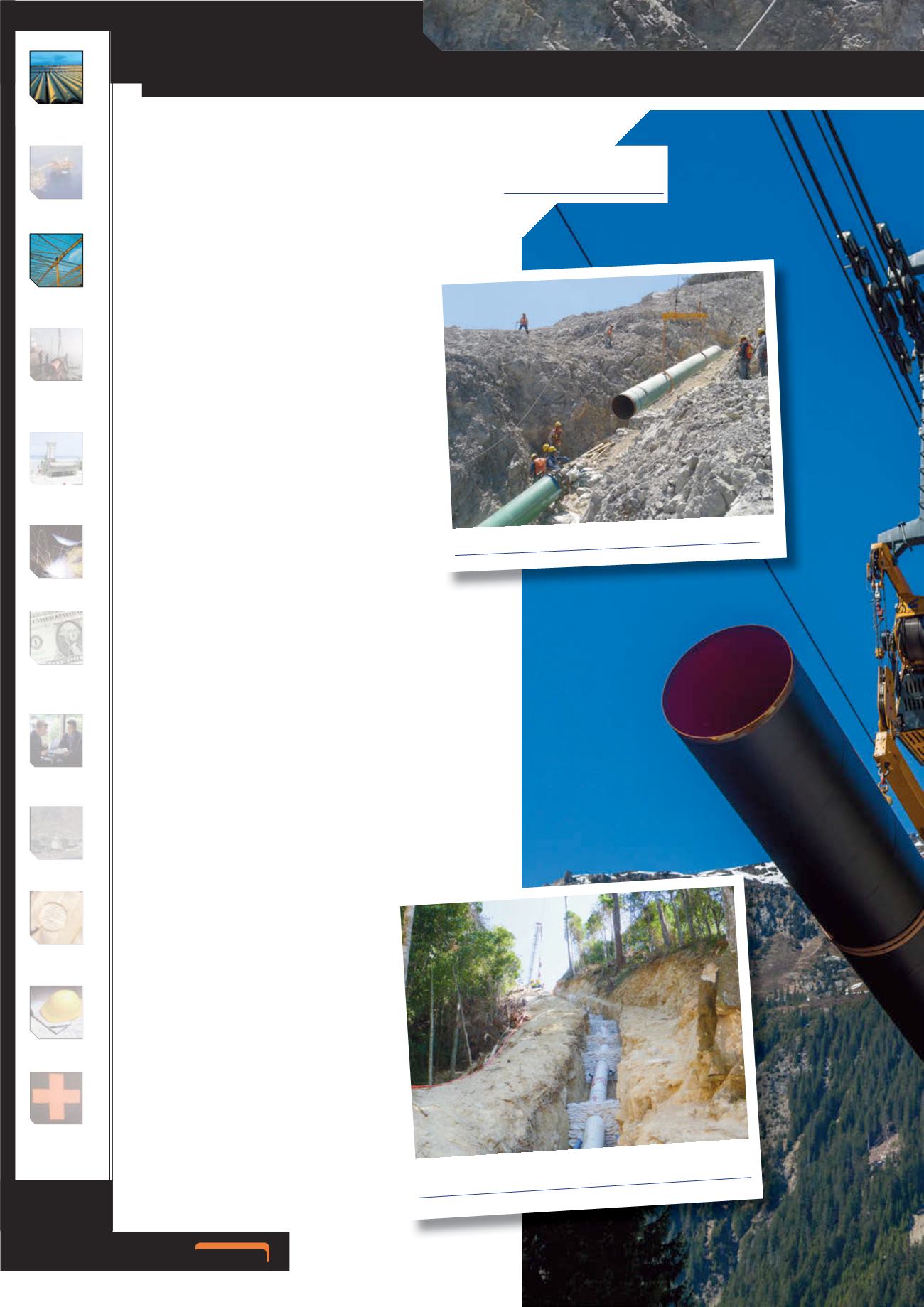

The pipe is precisely laid in inclined terrain.

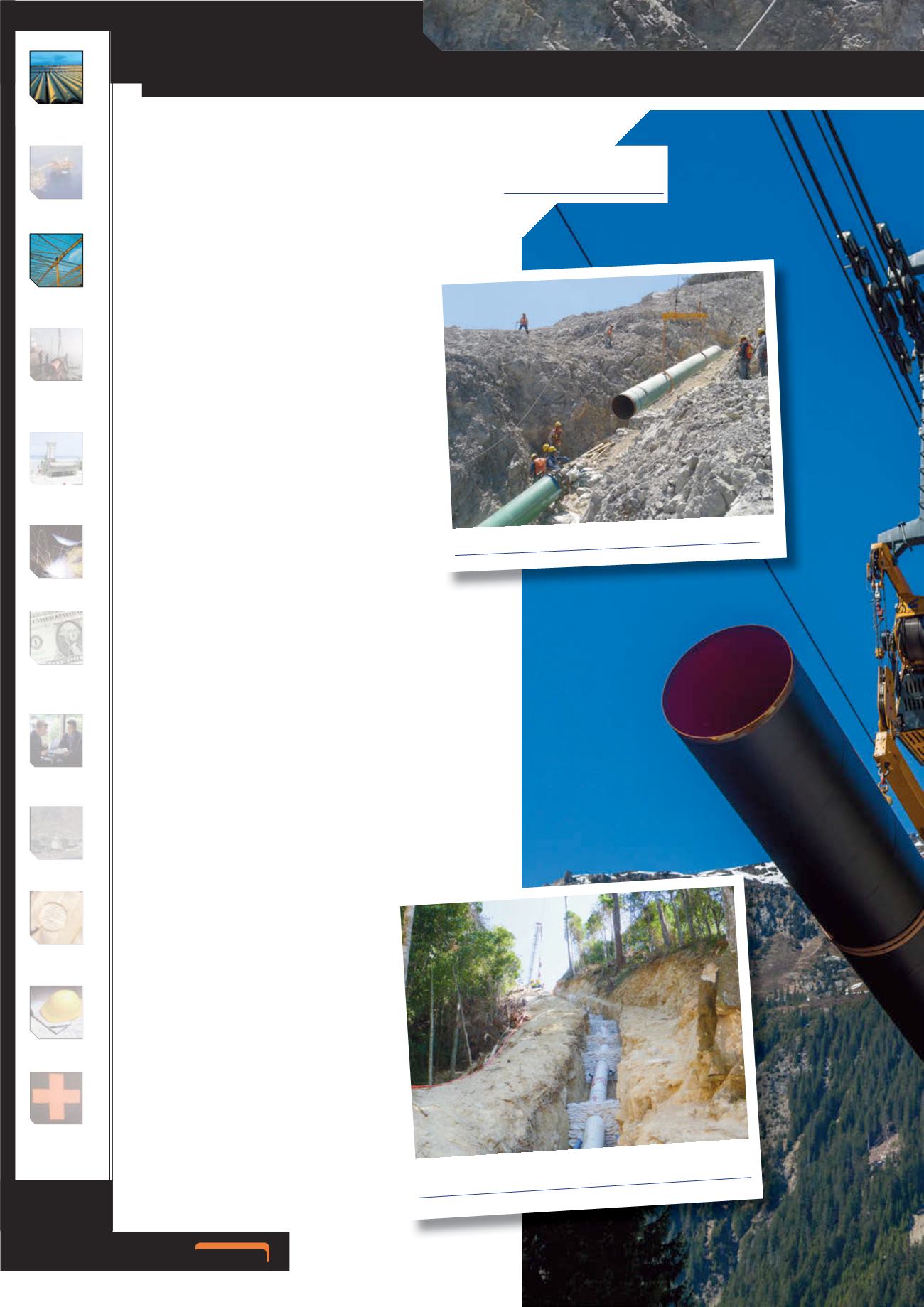

Narrow ROWs contribute to an environmentally friendly

construction.

LCS Cable Cranes