2015

contractors’

directory

67

ONSHORE

PIPELINES

OFFSHORE

PIPELINES

TURNKEY

CONSTRUCTION

HORIZONTAL

DIRECTIONAL

DRILLING

COMPRESSOR

STATIONS

WELDING

FINANCE,

STRATEGY

& ANALYSIS

TERMINALS

FEASIBILITY

STUDIES

RESEARCH &

DEVELOPMENT

MAINTENANCE

REHAB

14 sections, of which Hoelscher Wasserbau was awarded

10 sections for the dewatering works. For this project,

the company supplied five deep well drilling rigs, two

wellpoint drilling rigs, four trenchers for the installation of

horizontal dewatering, fifteen 4 x 4 trucks, 10 maintenance

vans, 30 pick-up trucks along with 100 employees. The

company installed over 5000 wellpoints, 95 000 m of

horizontal dewatering and 1600 deep wells to allow dry

and safe excavation of the pipeline. This was the largest

running construction site in Germany that required major

dewatering resources, which Hoelscher Wasserbau

supplied.

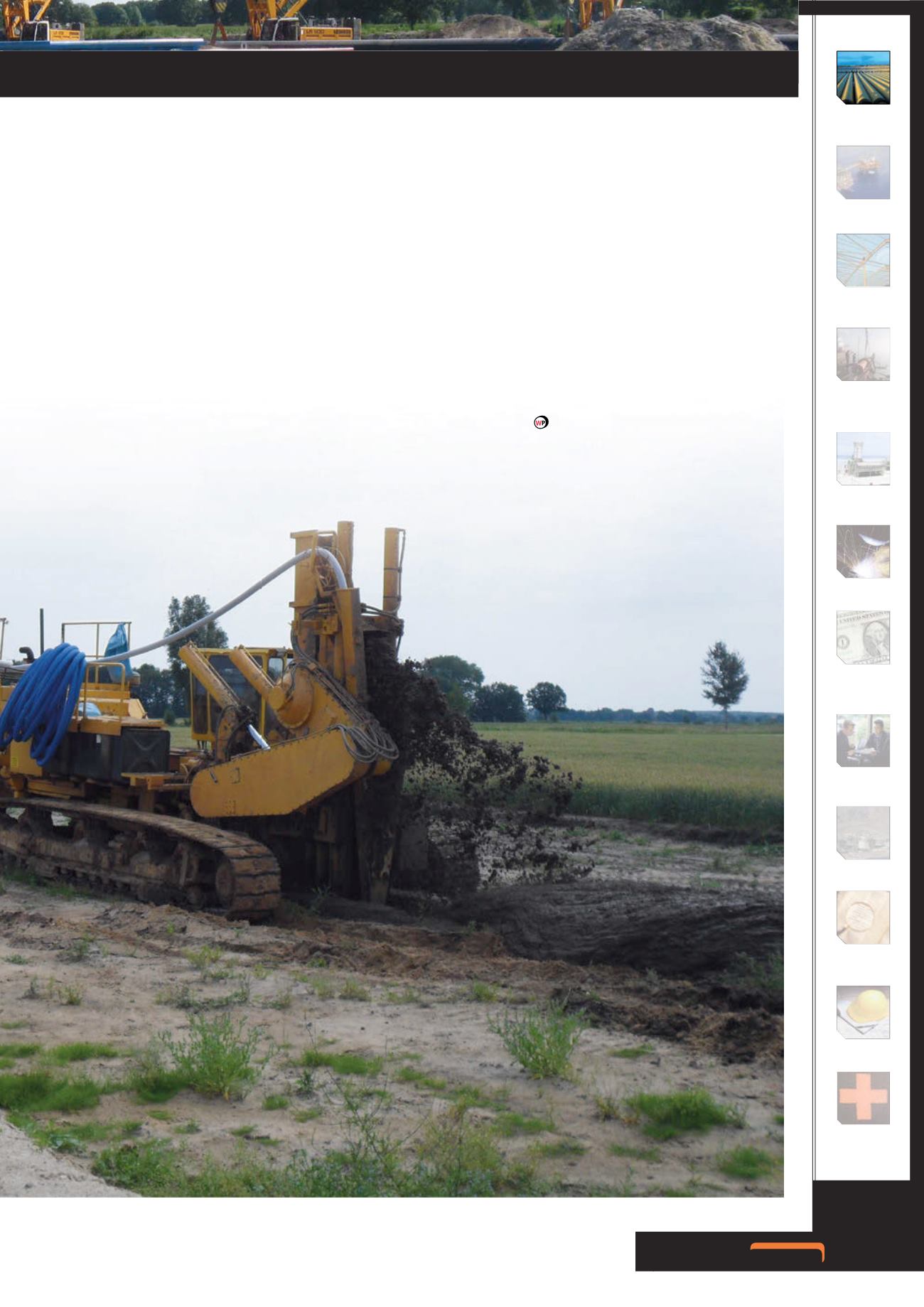

Angerlo-Beuningen Pipeline, the Netherlands

As part of the north-south pipeline route, the

Angerlo-Beuningen section was the part with the

most difficult requirements in terms of groundwater

management.

For dealing with the very high permeability,

and as a consequence of high flowrates of pumped

groundwater, a double trenched horizontal pipe

system of 72 000 m was installed. The groundwater

had a high content of iron. To avoid discharging

water with high iron content into channels or rivers,

it was necessary to treat the water in de-ironing

plants. In areas were de-ironing would have been very

expensive, the groundwater was transferred within

a closed system to a re-infiltration system and then

infiltrated back into the aquifer. This was achieved by

using the HW-DSI jet suction infiltration system. In

total, 16 million m³ of groundwater has been rejected

into the ground.