the design and development of InField Liners™ (IFL™) was

instigated.

A goal united

Robert Walters describes the conception of the IFL idea:

“It happened during a round table discussion, high up

in Petronas Towers, on the topic of the severity of the

corrosion being caused by sulfate reducing bacteria to the

internals of carbon steel subsea hydrocarbon pipelines.

The conversation revolved around the development of

the means of eliminating this corrosion, from which it was

determined that what was needed was the means with

which to put a corrosion resistant barrier between the

bacteria and the steel substrate.

“It’s achievable onshore in relatively straight and

short pipeline lengths but the technology didn’t exist at

that time to enable its application over long distances

or around short radius bends. It was therefore agreed

that this would be resolved by means of a research and

development collaborative agreement, led by APS and at

that point a simple concept became a realisable goal.”

The development of IFL

The project began in April of 2011 and operating under

the joint management of Petronas and Anticorrosion

Protective Systems, who are globally recognised pipeline

rehabilitation specialist engineers and contractors, it

has been possible for the project team to deliver a

substantially market-ready product within a three year

time-frame.

The IFL research and development project was aimed

at realising the primary objective of developing the

materials and technologies necessary to successfully

implement the installation of plastic liners into existing

and new subsea carbon steel pipelines being operated by

PCSB and other Petronas Companies, for the conveyance

of a highly corrosive hydrocarbon media. The IFL liner

will protect the internal pipe bore from corrosion of any

kind and will also offer an additional form of secondary

containment capability in the event of a rupture or

damage to the outer steel pipeline.

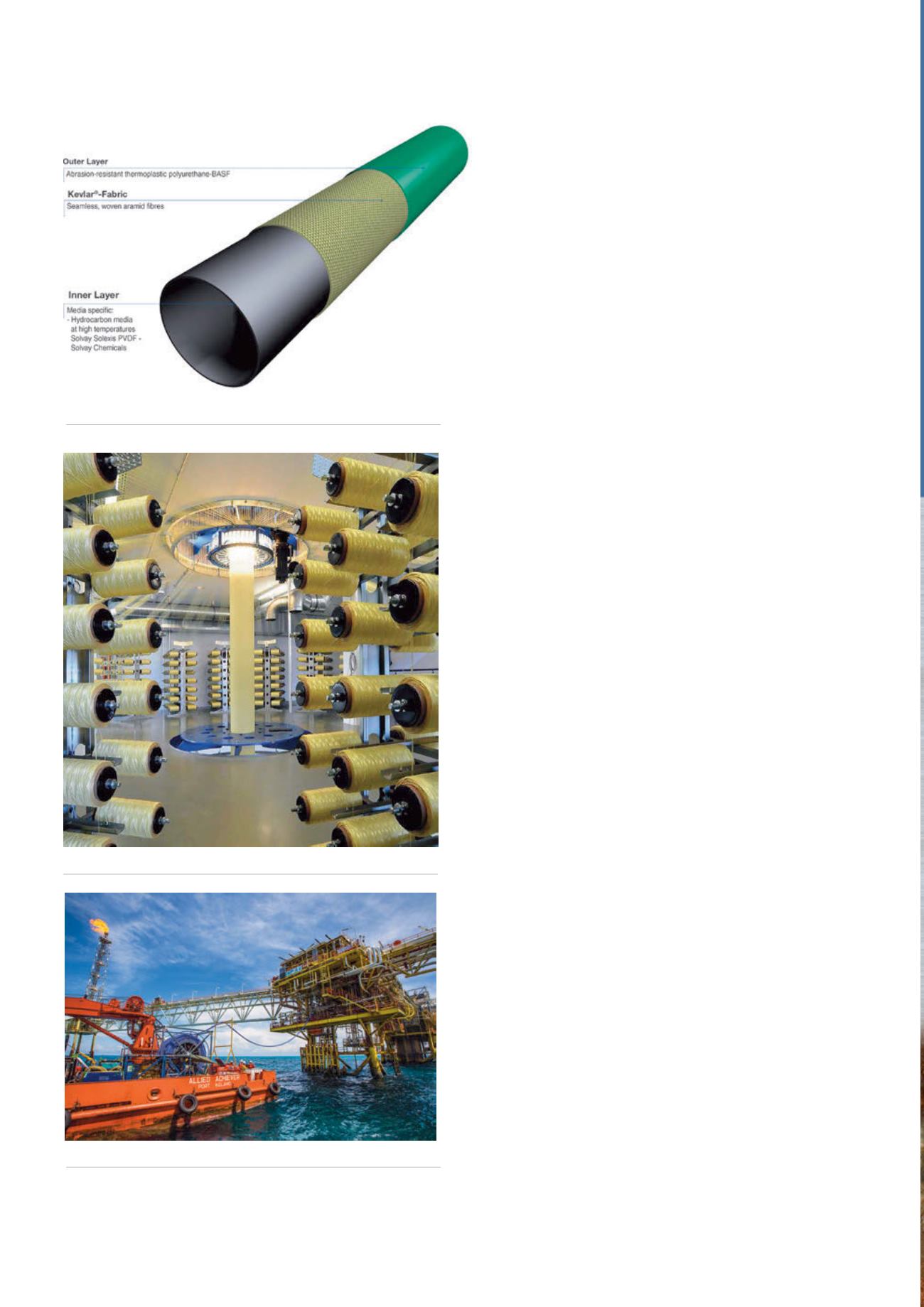

The project start point was the testing and

qualification of an existing nominal 8 in. Kevlar reinforced

plastic liner product, which is produced and manufactured

for the utility market by a German company, Raedlinger.

This material was selected as a viable starting point for

the project development work as it was recognised that –

although it had not been previously used for the purpose

of lining subsea pipelines – the general liner matrix

demonstrates many of the physical attributes that were

perceived as being necessary to contribute toward the

likely requirements for success, such as:

)

)

High tensile and good physical properties.

)

)

Moderate chemical resistance.

)

)

A high degree of flexibility.

Figure 2.

IFL liner matrix.

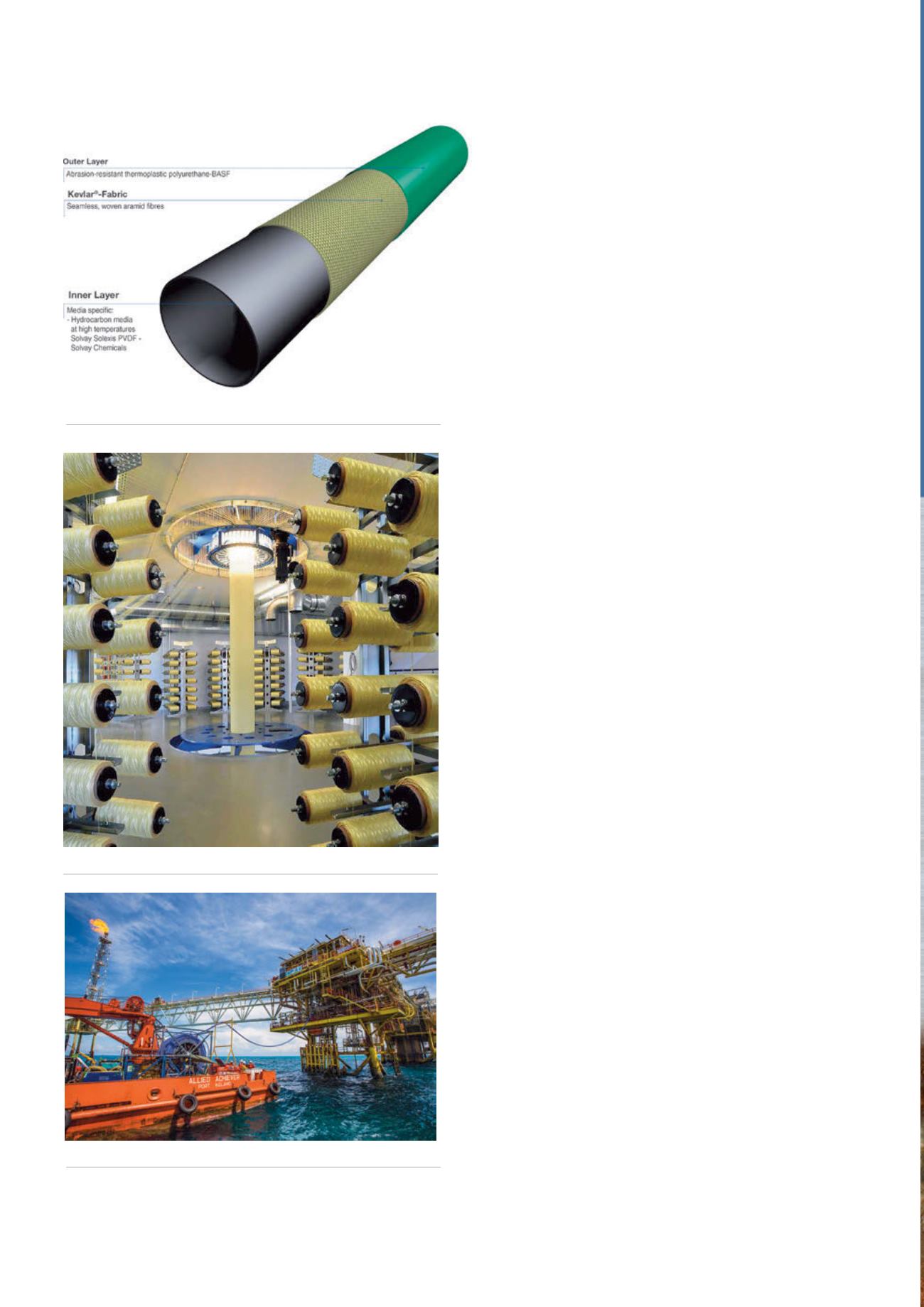

Figure 3.

IFL manufacturing.

Figure 4.

Liner launch from vessels.

60

World Pipelines

/

JUNE 2015