)

)

Inspection of subsea fabrication and repair welds.

)

)

Component geometry measurement including ovality

inspection.

The tools are developed and built around Sonomatic’s

extensive field experience with challenging subsea inspections

and integrate proven Microplus ultrasonic systems and

software with bespoke in-house designed scanner hardware.

The ultrasonic system is located in a subsea module mounted

on the ROV-iT to allow high reliability digital transmission of

data via the ROV’s communication systems. After positioning

by the ROV, the scanner is fully controlled by the inspection

team topsides. The ultrasonic system is highly configurable for

each specific application and provides

a comprehensive range of presentation

formats including A, B, C and D-scans.

The data is analysed real-time using

Sonomatic’s proprietary software routines

and analysis algorithms to allow accurate

and reliable results to be provided in the

form of single or composite images for

each inspection location. The full data

sets, including individual A-scans, are

also stored for detailed post inspection

analysis and comparison with previous

data.

The inspection systems are designed

for use with work class ROVs, and can

also be used with both wide-angle video

camera on a multiplexer and with LED

lighting systems, which are pressured-

rated to 2000 m. The tools are connected

to the ROV via a short umbilical, which

supplies all electrical and motion services.

Data is transferred in real time back to

the surface through the ROV umbilical

and no additional cabling is needed.

Key features:

)

)

Subsea deployment of a range of

advanced ultrasonic techniques with

proven industry leading performance.

)

)

Subsea deployment of alternating

current field method (ACFM) for

surface crack detection.

)

)

Inspection for a range of degradation

mechanisms including corrosion,

erosion and cracking.

)

)

Inspection for internal liner

detection and component geometry

determination.

)

)

Flexible riser inspection.

)

)

Full 360˚ coverage.

)

)

Scan lengths of 1 m.

)

)

2000 m depth-rated.

)

)

Horizontal and vertical scanning.

Key benefits:

)

)

Cost-effective inspection.

)

)

No dive-support vessel (DSV) required.

)

)

Deepwater inspection capability.

)

)

Diverless operation reduces personnel risk.

)

)

Fully ROV-integrated operation.

)

)

Work class ROV deployable.

+1-918-259-3050 |

| vacuworx.com

Lift materials faster, safer, smarter with Vacuworx Lifting Systems.

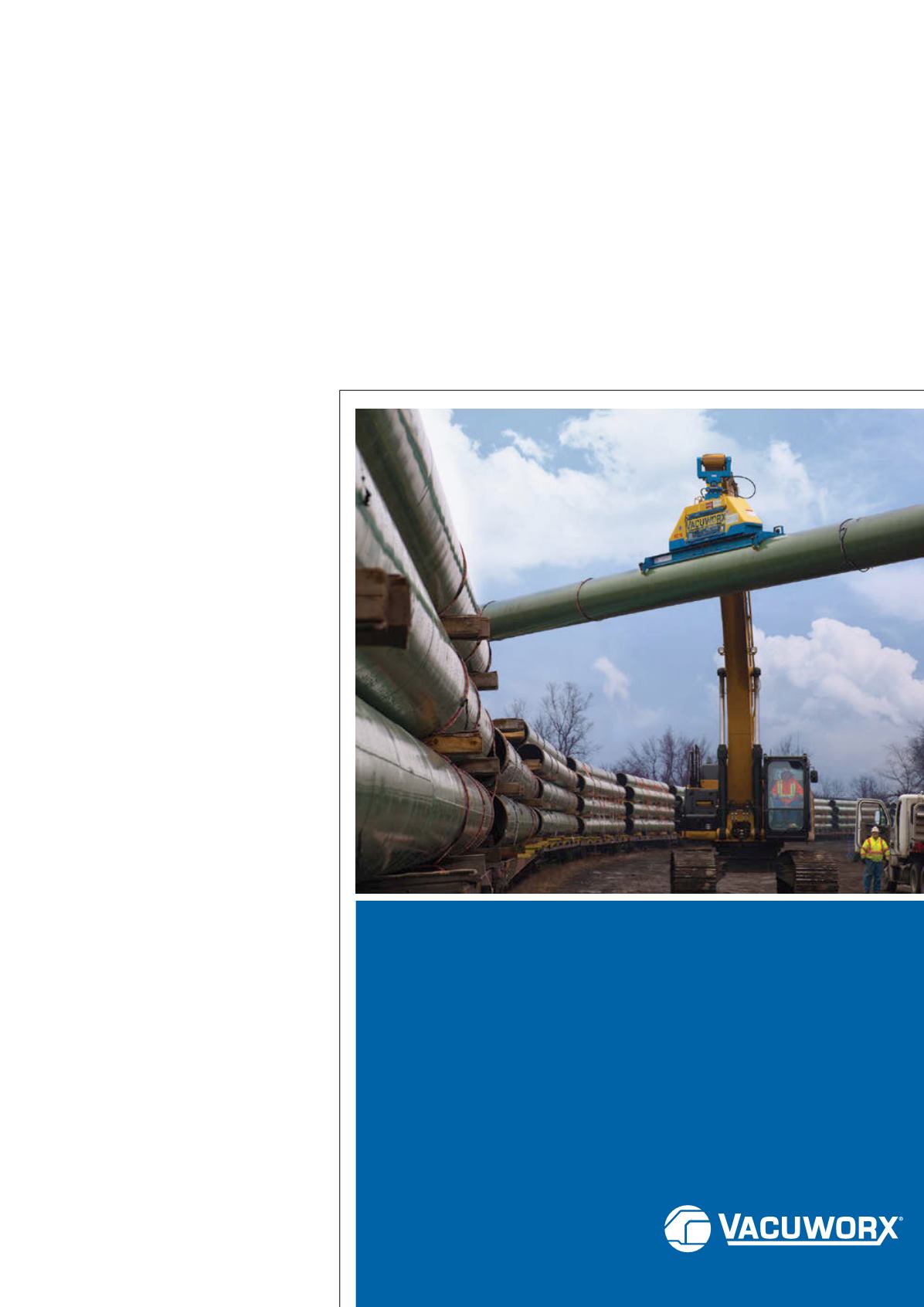

For over 15 years Vacuworx has been manufacturing the safest, most economical lifting

equipment for heavy-duty pipe, plate, slab, concrete barriers, and HDD drill stem.

• Faster load and unload cycles means less downtime for your workers.

• Wireless remote operation is safer than hooks, slings, or chains.

• Full inventory available for immediate purchase or rental.

• Parts, service, and technical support available 24/7 365 days a year.

Visit vacuworx.com or contact

Vacuworx for information.

TEN TIMES

more pipe.

HALF

the man hours.