computer and odometer. Special design cups were developed that

provide two important features:

)

The cups easily collapse and give minimum friction in the small

diameter pipe. As a result, there will be minimal difference in

pressure in both pipe sections. This is important at the point

where the pig enters and leaves the reduced bore: a high

differential pressure would result in a large expansion of gas

when the pig enters the large section again and an associated

speed excursion. This has now prevented and all data collected

is useful for evaluation!

)

The cups are highly flexible and have sufficient self-centering

capability so that the pig will travel in a good inline position

through the remainder of the pipeline.

Again, before the field work was conducted, a real 1:1 mock up

model was built in the yard with an exact copy of the pipe reducer,

in order to ensure a smooth transition of the pig in both ways.

Prior to the inspection run, a cleaning pig with magnets and spider

nose was run through the line in order to ensure that especially

the smaller pipe section was free from debris that could impact

the passage of the inspection tool. A dual size caliper pig was run,

with two measurement units, in order to get proper geometrical

data from all pipe sections. Inspection data proved to be 100%

within specification and multi diameter lines are now inspectable

without the need of exorbitant prices or the need of high impact

mechanical work and sectionising of the various diameters.

High-flow pipelines

MFL tools will function properly up till velocity of approximately

4 m/s. The faster the tool moves, the stronger the induced

magnetic field that originates from eddy currents induced by

the moving magnetic field. The eddy-current-induced magnetic

field works opposite the magnetic field of the tool, reducing

the overall level of magnetisation. As a result, the magnetisation

will drop below 10 kA/m and inspection data will not meet the

required level of accuracy and confidence. Reduction of gas flow

would be required in order to achieve a successful inspection.

For several reasons, reduction of gas flow may not be feasible,

be it from economic perspective or from power strategic

considerations.

In order to move the tool through a high production

pipeline, an active speed control unit has been designed, which

regulates the amount of gas bypass through the tool while

moving through the pipeline. Again, a trial set-up is built in

order to investigate the behaviour of the tool at various speeds

and the computer unit of the speed control device is tested.

The bypass valve system is also tested in static and in dynamic

conditions in order to get a close picture of the system in the

pipeline. Finally, the fail-safe mechanism is tested in order to

ensure that, whatever the condition of the tool and the gas

flow, the inspection tool will always travel to the receiving

station. The high resolution MFL tool with inertial navigation

system and active speed control unit (ASCU) is brought to

the field to inspect a 28 in. x 250 m long distance subsea gas

transmission line. The operation for the ASCU is evaluated upon

completion of the pig run and the tool has travelled at the pre-

set conditions of 3 - 4 m/s in a gas line with velocity of 5 m/s at

launch towards 9.5 m/s at the receiving end.

Conclusion

In this article, several scenarios of pipeline conditions, either

from a constructional or from an operational point of view that

would be considered ‘non-piggable’ in the convectional way of

speaking, have been dscussed. By using new design of the MFL

module and associated technology, difficult-to pig pipelines are

now within the scope of pipeline inspection and pipeline integrity

management.

Figure 4.

The velocity profile of a low-flow pipeline: 700 hours

at an average of 0.04 m/s.

Figure 5.

MFL tool with Active Speed Control successfully

retrieved after long distance subsea pipeline inspection.

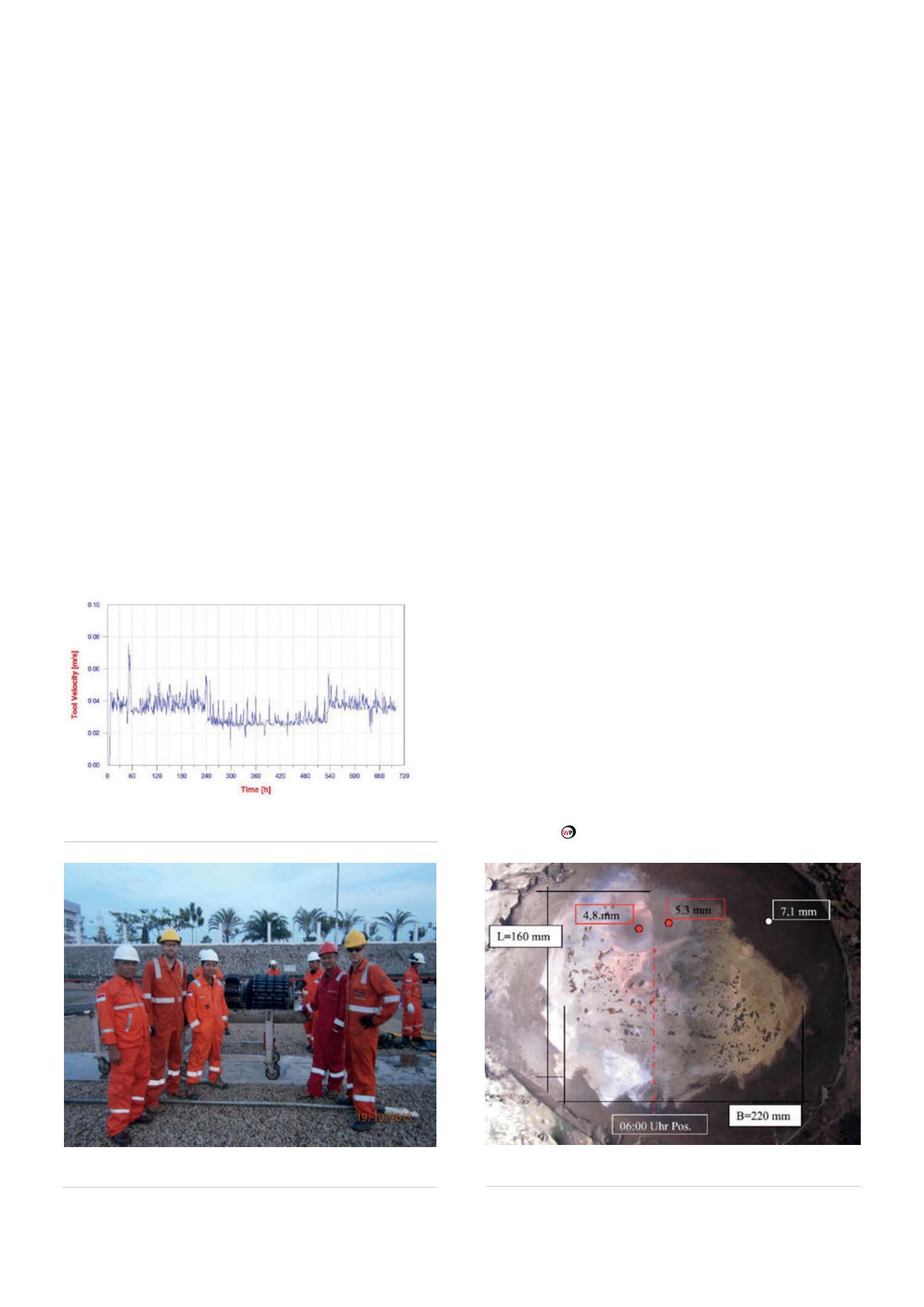

Figure 6.

Pitting corrosion accurately detected and sized by

XHR MFL tool.

52

World Pipelines

/

JUNE 2015