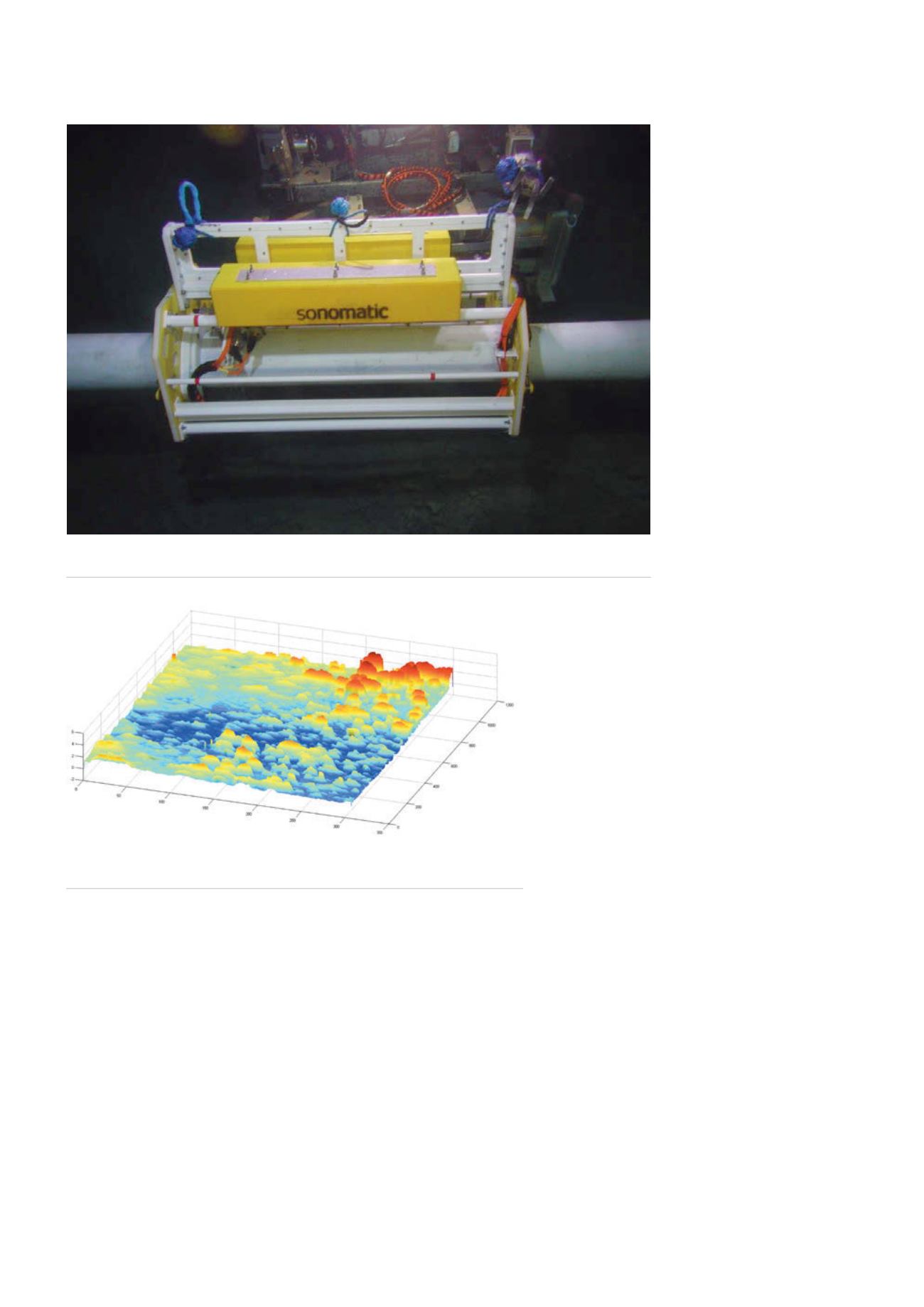

using the ROV-iT, an ROV-deployed ultrasonic inspection tool

developed by the company.

A major objective of the inspection was to validate

absence of low level degradation so that a case could be

made for operation without the need for inline inspection.

Since the coverage for the subsea inspection was low, meeting

this objective was dependent on providing a highly sensitive

inspection with accurate wall thickness measurements on a

fine scan increment.

The inspection performance achieved at a depth of

1435 m, through a 3-layer polypropylene coating, matched that

in shallow water, demonstrating Sonomatic’s capability to

deliver its world leading corrosion mapping accuracy even at

great depth. The results of the detailed analysis of inspection

performance, as achieved in

the field, were central to the

integrity assessment. This was

based on statistical methods

developed by Sonomatic

for planning and evaluation

of targeted inspections on

unpiggable gas pipelines. The

inspection demonstrated that

the probability of degradation,

with potential to threaten

integrity for the line as a

whole, was within acceptable

limits.

Sonomatic’s industry

leading measurement

performance was central to

ensuring this objective was

met and that the result was a

substantial cost saving to the

client. An inline inspection,

which would have relied on

a very expensive deepwater

launch of the intelligent

pig, was avoided. The

subsea inspection work

was completed safely and within the planned

schedule, with Sonomatic’s equipment operating

effectively and reliablly throughout the

campaign.

New techniques for subsea

deployment

Sonomatic’s ROV-deployed tools have been

designed for inspecting pipelines, risers, caissons

and structural assets. The tools are adaptable,

operating on both horizontal and vertical pipes

ranging from 6 - 30 in. dia. A range of ultrasonic

inspection techniques can be deployed including

corrosion mapping, time of flight diffraction (TOFD),

automated shear wave pulse echo and component

geometry measurement.

The inspection techniques, and combinations

thereof, that are deployed means the following applications

can be addressed:

)

)

Verification of ILI tool findings.

)

)

Targeted inspection for unpiggable pipelines.

)

)

Inspection for internal corrosion and erosion.

)

)

Inspection for preferential weld corrosion/erosion.

)

)

Inspection for fatigue or stress corrosion cracking.

)

)

Inspection for wet H

2

S damage in sour service.

)

)

Inspection for chloride pitting/SCC in corrosion resistant

alloys.

Figure 1.

Inspection carried out using the ROV-iT, an ROV-deployed ultrasonic inspection tool

developed by Sonomatic.

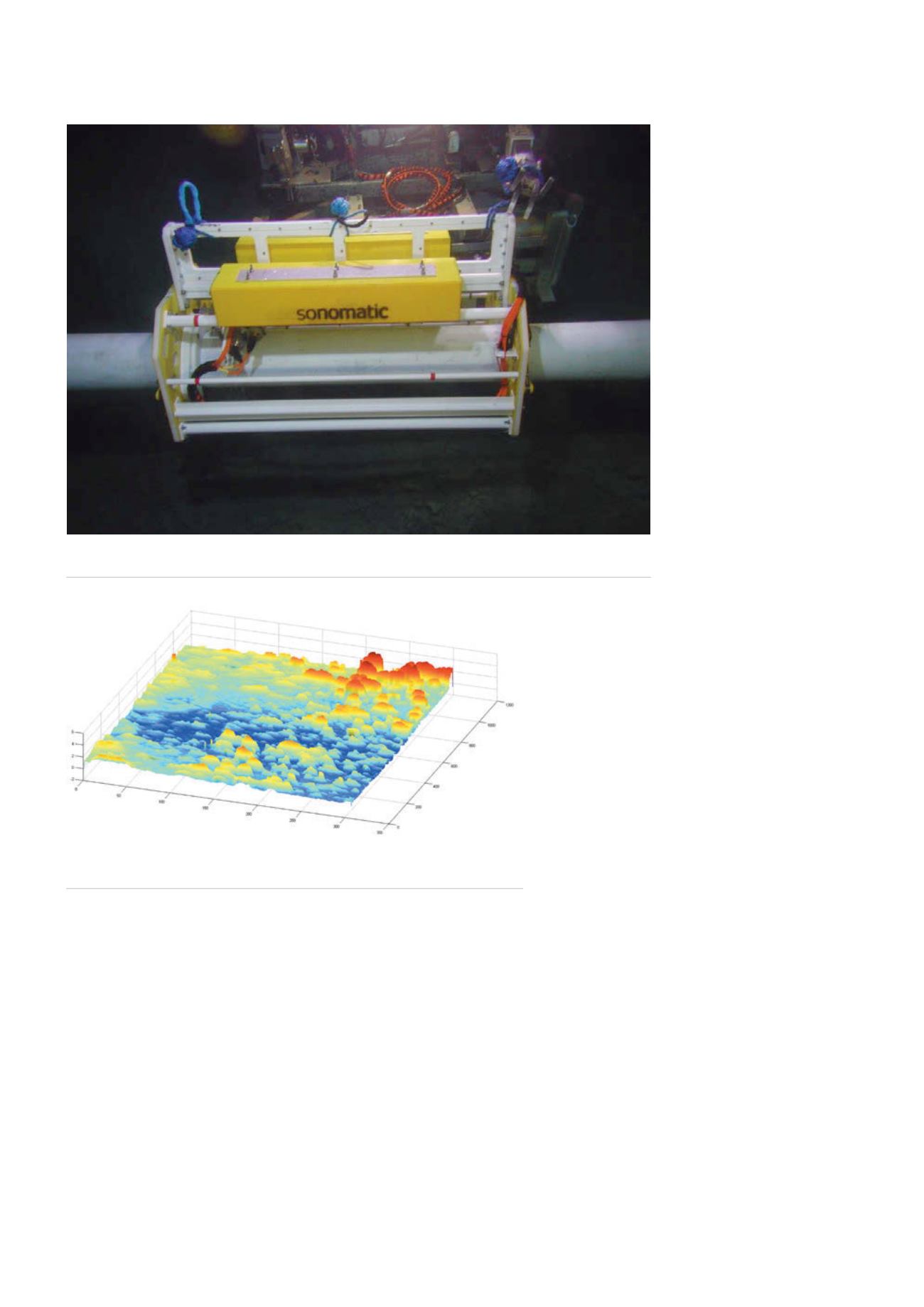

Figure 2.

Corrosion map of region of subsea pipeline with internal

degradation.

68

World Pipelines

/

JUNE 2015