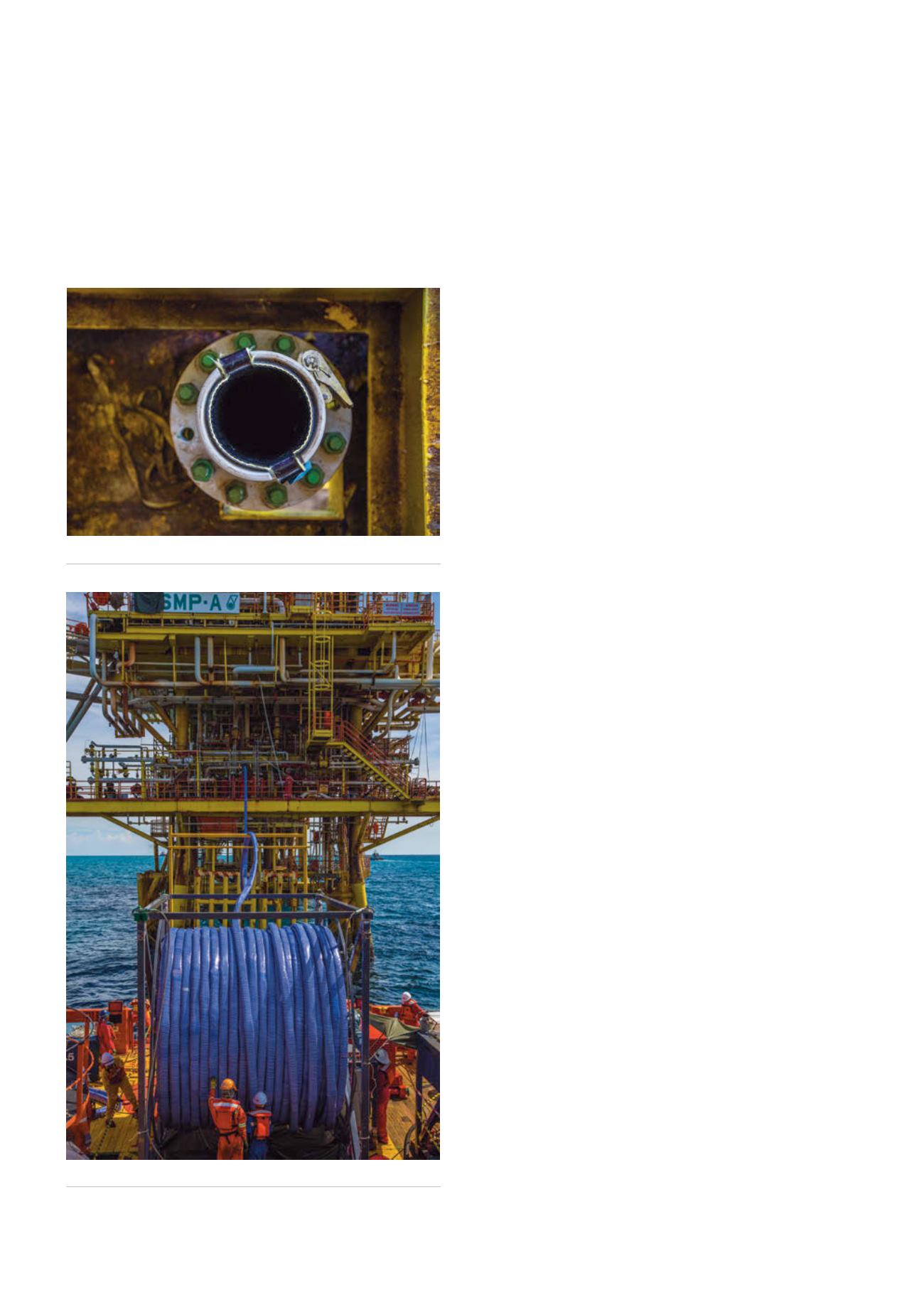

drum was positioned on the on the deck of a work boat

from where the liner was unspooled.

A feeder cable was fired through the pipeline during

the final cleaning and gauging procedure, which was used

to pull back through the liner installation winch cable

for connection to a towing head that was located on the

leading end of the liner.

Engineering determined the specific winching loads

necessary for the liner insertion using predictive IFL

software. The winch packs used for installation came

equipped with load cells and override devices to interrupt

operations in the event of greater than predicted loads

during the winching. The operator could also set the

devices to cut out automatically at a given load if the

engineered safety factor relative to the liner yield strength

were approached. In this instance, however, and as with

most 0.5 - 5 km liner insertion calculations made, the

forces actually incurred proved to be no more than one-

tenth of the liner’s ultimate tensile yield strength.

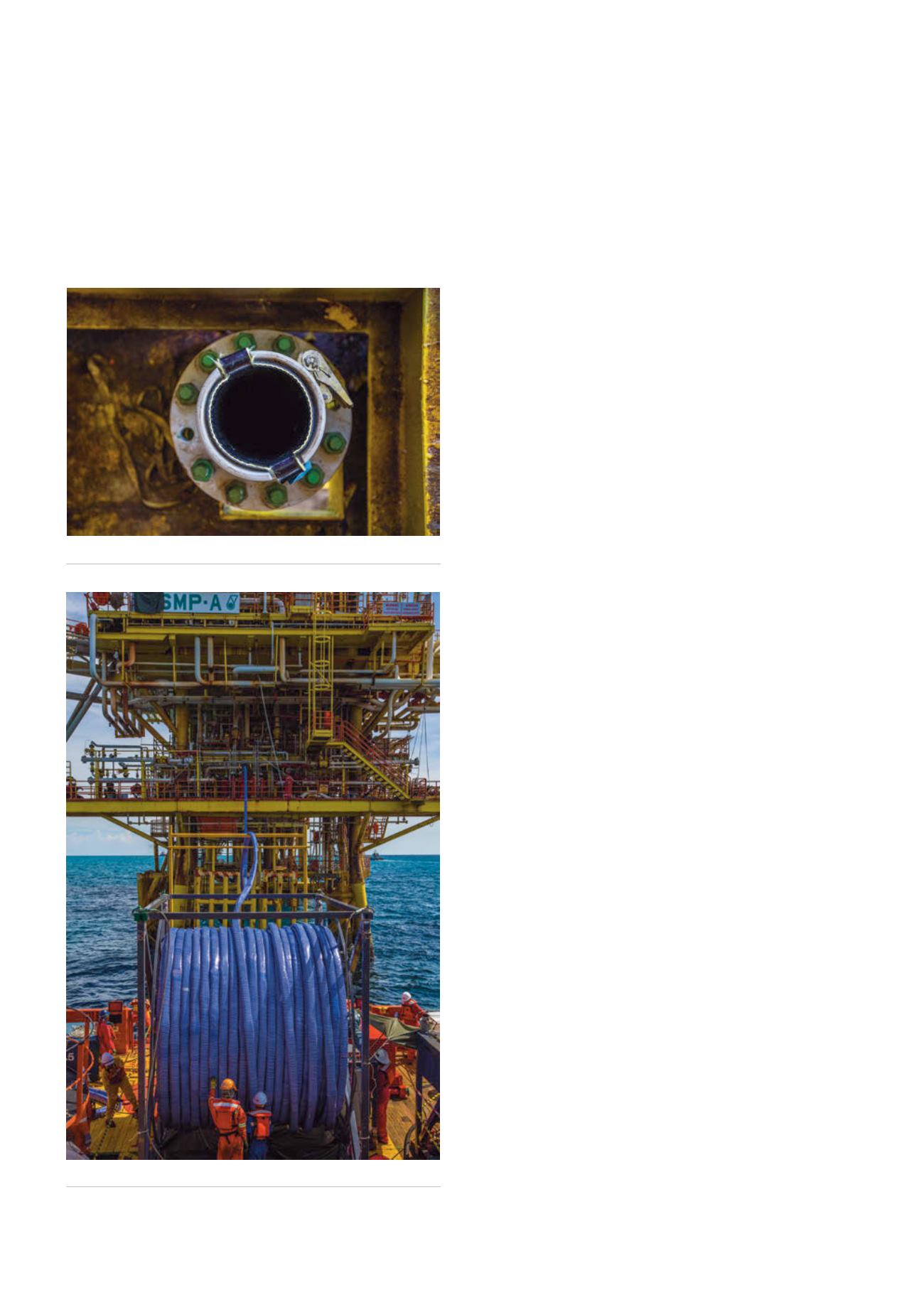

Installation of IFL end termination coupling devices

at riser flange locations concluded the liner installation

process. After the IFL was drawn through the entire

pipeline length, the liner was then pressurised to inflate

it. The liner, being manufactured to fit the diameter of the

host bore, then expanded to form an intimate fit with the

inner wall of the pipe.

Installation of the IFL end termination connectors,

which ensures reliable compression seals and restraint

at the liner ends, followed liner inflation and fitting

process. Hydrotesting the relined pipe certified that

the rehabilitated pipeline system was now ready for

recommissioning and return to operation.

Petronas estimates the service life of these lines to

have been extended by at least 30 years.

Manufacturing

IFL materials are manufactured under strictly controlled

conditions. Only raw materials of the highest quality from

approved specialist suppliers are selected and utilised,

having first been subjected to vigorous quality control

and testing, in full conformity with a detailed IFL liner

manufacturing and test plan.

Every element of the manufacturing procedure is

carefully and continuously monitored and controlled

with real time computer assessment and feedback so

as to ensure absolute precision. Once commenced and

stabilised, the manufacturing process is a smooth and

constant process until the full length of the desired liner

has been produced. Every facet of the liner production

quality assurance is recorded and the produced liner

quality is thereafter further verified by extensive testing

prior to factory acceptance and certification. Finally, the

liner is dispatched to the customer.

IFL is reeled flat packed, onto specialist shipping drums

designed to be containerised in conventional high cube

containers, with each drum capable of taking up to 5 km of

liner, dependent upon diameter.

At the moment the production tooling is available for

the 6 in. and 8 in., with 10 in. and 12 in. planned for early

2016 and thereafter ultimately up to 18 in.

IFL applications

IFL offers the pipeline industry a viable, fast and

economical option to new-lay pipeline replacement. IFL

Figure 7.

Liner insertion.

Figure 6.

Liner re-rounded before end connector installation.

64

World Pipelines

/

JUNE 2015