A pipeline risk management scheme involves identifying

and assessing the susceptibility and severity of credible

threats to pipeline integrity, determining the likelihood of

various failure scenarios and calculating their likely impact

on people and the environment. The resulting failure

probabilities and consequence values generate risk metrics.

These factors are then used to develop various mitigation

and inspection strategies to maintain pipeline integrity.

There are two groups of people in a pipeline company

who benefit from a risk assessment, namely engineers

and managers, with each having different areas of

responsibility. An effective risk model should generate

information that addresses the responsibilities and

concerns of both these groups.

Risk modelling

A risk model must consider the susceptibility of a pipeline

to various hazards, the probabilities of different failure

scenarios together with the consequences arising from

each of these failure scenarios, i.e. the model needs to

address the following questions:

)

What can go wrong?

)

How likely is it to happen?

)

What are the consequences if it does happen?

Various techniques are available to evaluate risk

factors for different threats and failure scenarios. These

range from descriptive qualitative approaches based on

engineering judgement, which generate relative risk values,

through to detailed mathematical analyses in a fully

quantitative assessment which express risk in absolute

terms. However, the degree of model complexity used to

determine a risk factor does not necessarily reflect the

accuracy of the results.

Semi-quantitative risk models of varying complexity

have been promoted for a number of years, but in the

authors experience the algorithms and weighting factors

commonly found in such models still rely heavily

on engineering judgement, which can lead to

inconsistencies across assessments. They also

often lack sufficient resolution for meaningful

assessments.

In most cases there is insufficient information

available to justify applying a fully quantitative

approach to assessing risk. However, with the

growing availability of detailed pipeline data

such as ILI results, CP survey data and geospatial

information, operators now have an expectation

that pipeline risk models will provide a more

consistent and numerically based assessment of

risk levels. As an example, determination of the

consequences of failure is a key component of risk

models and the availability of GIS-based tools is

improving the definition of hazard zones and the

impact on receptors in these zones.

An effective numerically based pipeline risk

model should incorporate mathematical logic

into its decision making process and generate risk

factors in a consistent manner. Also, in addition

to the standard risk factor (PoF x CoF), individual

and societal risk levels feature in many pipeline

regulations so there is a need for the model to

create the parameters necessary to calculate these

risk values along a pipeline.

It is essential the model incorporates a

transparent decision making process that

provides a clear audit trail. Regulatory authorities

increasingly demand auditability so this effectively

rules out many black-box software solutions where

a single click generates an answer but the process

is opaque.

QPRAM risk model

MACAW Engineering in collaboration with ROSEN

Integrity Solutions developed QPRAM, a numerical

pipeline risk assessment model, as a result of its

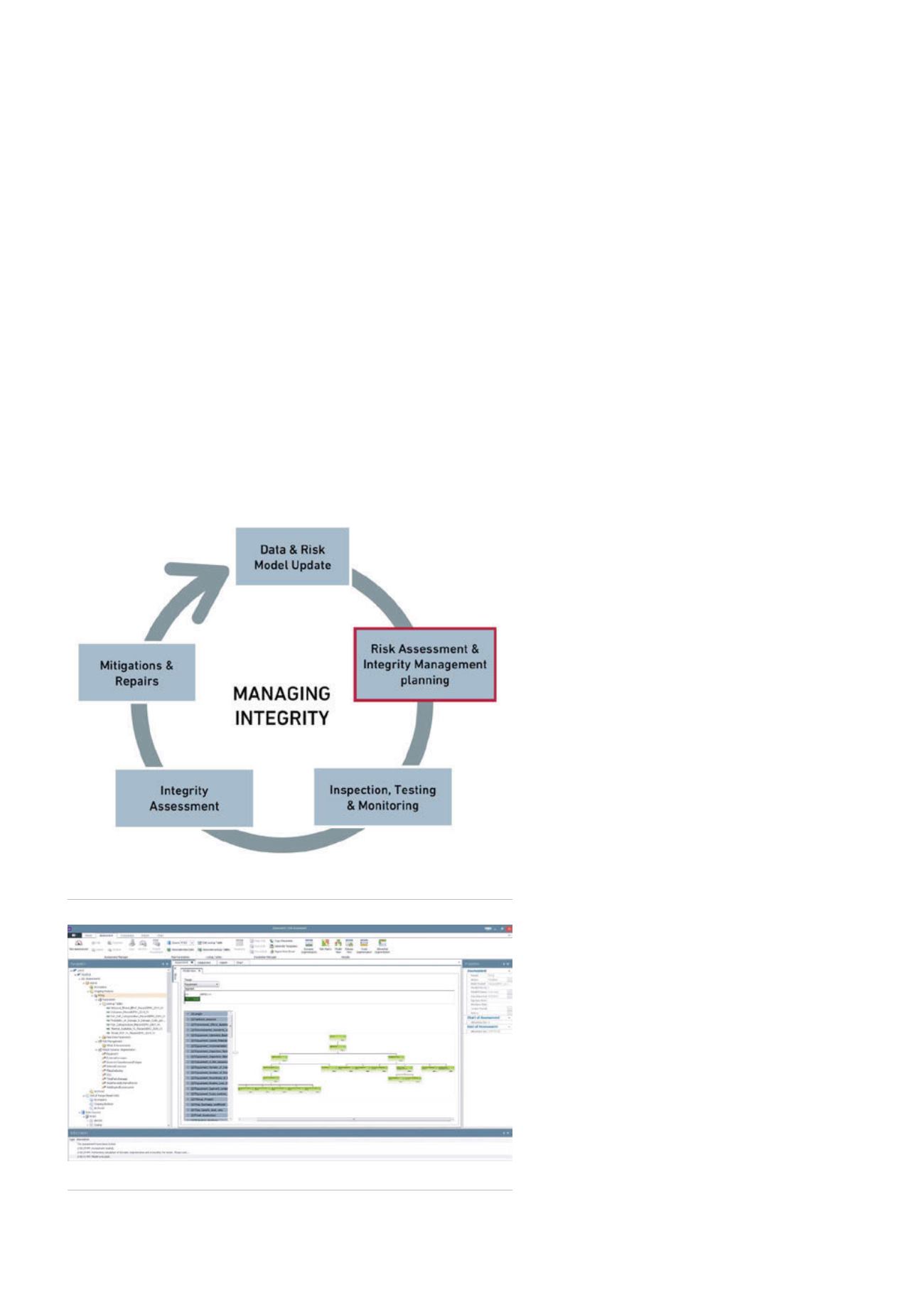

Figure 1.

The integrity management process.

Figure2.

Risk model view.

44

World Pipelines

/

JUNE 2015