contractors’

directory

2015

WELDING

MAINTENANCE

OFFSHORE

PIPELINES

RESEARCH &

DEVELOPMENT

84

ONSHORE

PIPELINES

REHAB

TERMINALS

FEASIBILITY

STUDIES

FINANCE,

STRATEGY

& ANALYSIS

COMPRESSOR

STATIONS

HORIZONTAL

DIRECTIONAL

DRILLING

TURNKEY

CONSTRUCTION

S

erimax is a world-leading welding solutions provider

and has been at the cutting edge of welding

technology for over 40 years. The company offers

fully integrated welding and fabrication solutions

for offshore and onshore projects. Operating in the most

extreme conditions and challenging environments, Serimax

tailors each project to the specific requirements of its

clients.

Serimax carries one of the largest fleets of specialised

pipeline welding equipment in the world and has an

unrivalled pool of welding specialists across five regional

hubs, along with its centralised global welding technology

group.

Backed by its experience and capacity to continuously

innovate, Serimax remains the market leader, where

consistent results are commonplace. The company’s track

record is testimony as the world leader of excellence in

offshore, land, subsea and fabrication welding.

Serimax’s clear strategy enables it to develop

technologically advanced welding solutions –

taking welding from an art to a science. Offering

fit-for-purpose equipment, providing experts who

work both safely and efficiently whilst managing

turnkey projects, the company’s goal is to create

and deliver both innovative and high performance

industrial solutions to ensure success.

Serimax endeavours to answer your most

complex challenges, by providing groundbreaking

technology.

Recently completed/ongoing offshore projects:

F

COOEC for PTTEP, Zawtika Phase 1B, Myanmar –

three Saturnax stations, 45 km of 18 in. welds,

14 km of 14 in welds, 30 flanges of 14 and 18 in., all

severe sour service, 4966 welds.

F

Subsea 7 (Borealis) for

PTTEP, Ten Subsea7,

Ghana – 35.5 km of

8.62 in. welds, 33.8 km

10.75 in. welds, 3199

welds.

F

Sapura Acergy (Sapura

3000) for Total,

Maharaja Lela, Brunei –

three Saturnax stations,

849 welds all 18 in.

F

TL Offshore for PGN

Kepodang, Indonesia –

three Saturnax stations,

16 174 welds of 14 in.,

195.9 km.

F

Technip Marine (G1201)

for SSPC, Malikai,

Malysia – four Saturnax

stations, 7816 welds of 8

and 10 in.

F

Subsea7 (Borealis), Ehra North Ph. II, Nigeria – three

Saturnax stations, 970 welds both 11 and 13 in.

Recently completed/ongoing onshore projects:

F

Spac Artère des Flandres – two Saturnax stations for

GRT Gaz France, 21.887 km 36 in. (14.6 mm, L485MB),

sweet service.

F

Al Royaba UA-6 Pipeline seg. II – two Saturnax stations

for Saudi Aramco, Saudi Arabia, 51.75 km 48 in. (9.5 mm,

X60) 38.25 km 46 in. (9.5 mm, X60), all sweet service.

F

Bonatti Kashagan – three Saturnax stations for NCOC

Kazakhstan, 6884 welds, 28 in. (19 mm, Clad 625).

F

Denys Arc de Dierrey for GRTGAZ France – three

Saturnax stations, 2806 welds 48 in. (13 - 22.7 mm,

L485MB), sweet service.

Serimax

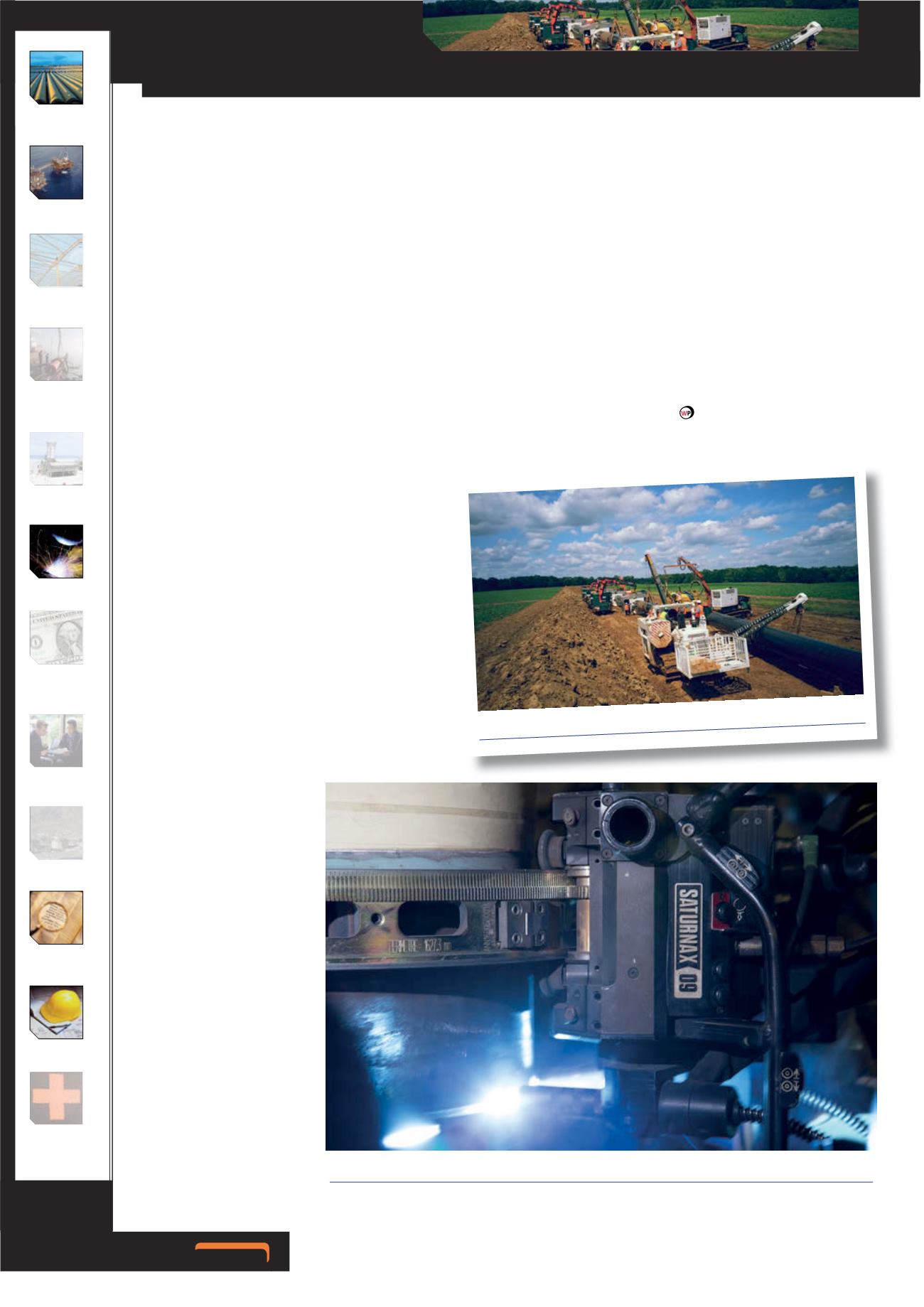

Saturnax 09 J-Lay welding operations on board Subsea 7 Borealis in the Gulf of Mexico.

Onshore welding solutions, Arc de Dierry, France.