settings to determine the optimal

drive configuration using the

9000XDrive software program. The

tools facilitate upload and download

drive parameters, which can be

changed, saved and ported back to

the drive and then printed or saved

to a file for future reference. Other

operator functions included in the

software are the ability to set

references, start and stop the drive,

and monitor and display signals and

values.

Leverage integrated

power assemblies

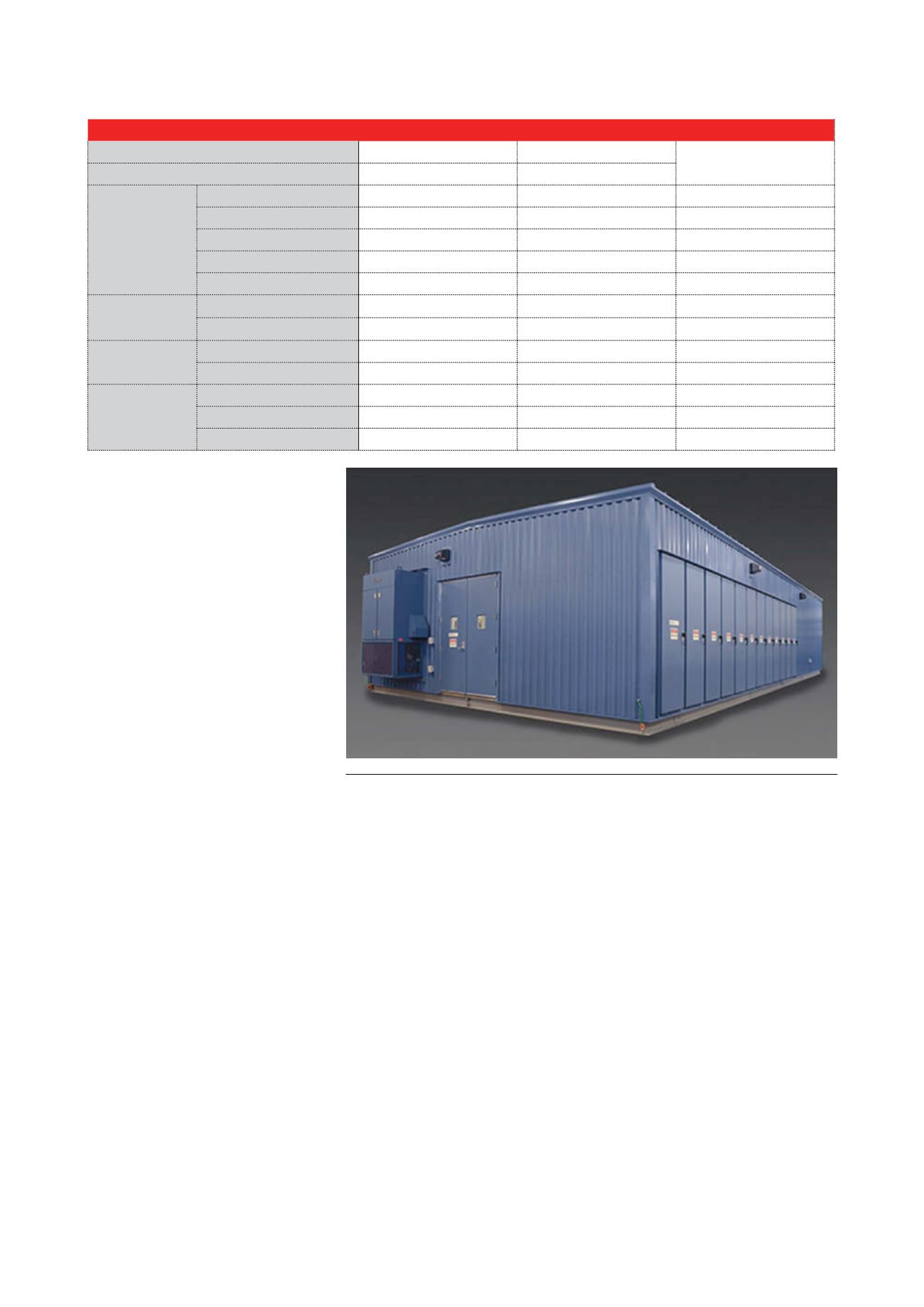

Integrated power assemblies (IPAs)

– sometimes called e-Houses – are

ideal for either new mine sites or for

adding capacity at existing facilities.

They are prefabricated metal

enclosures housing power

distribution and industrial control

equipment, such as switchgear, motor

control, power generation and

communication systems

custom‑tailored to individual

specification. IPA implementations

save time, reduce cost and simplify

expansion efforts.

Existing power distribution

centres (PDCs) can be retrofitted with

IPA solutions to extend lifecycles, add

processing power and meet

regulatory requirements. An alternate

containerised, mobile solution allows

the owner the ability to transport a

substation to multiple locations,

thereby reducing cycle time to

redistribute power, where needed,

while simultaneously making

maintenance much faster and easier.

The modular design of Eaton’s

IPAs reduces complexity and

simplifies installation. A rugged,

welded I-beam base provides a solid

foundation for internally mounted

components, allowing either slab or

raised‑on‑piers installation. IPAs can

be built with galvanised steel,

stainless steel or aluminum

construction to address any variety of

site environmental conditions.

The engineered IPA arrives

pre-wired, pre-assembled and

pre-tested to reduce site installation

costs and speed to production.

Onsite contractor installation

expenses are virtually eliminated

because all equipment is installed,

wired, tested and ready to use upon

delivery. A single, coordinated IPA

shipment eliminates multiple onsite

handling and storage expenses. Staff

training maintenance costs are also

reduced as the equipment comes

standardised with proven support

documentation.

These factors can significantly

reduce timeline to production, which

consequently allows earlier startup

of both the facility and the revenue

stream. This jumpstart on uptime

may seem minor, but it can translate

into hundreds of thousands of

dollars for the facility in terms of

speed to first production. If that is

not enough, there are tax breaks in

some countries, allowing accelerated

depreciation of the asset that are also

available as an incentive.

Integrated power assembly with I-beam foundation base.

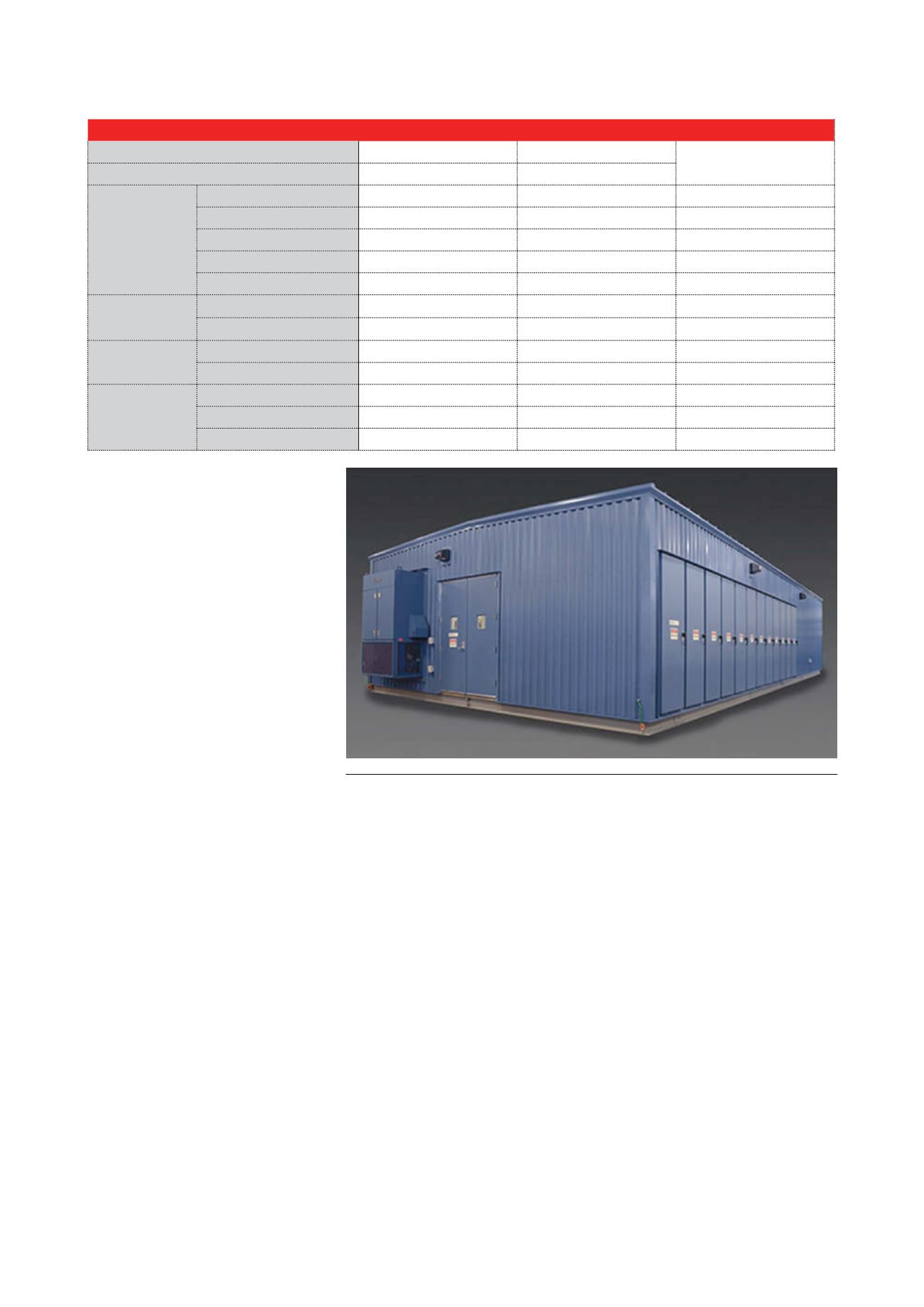

Table 1. Total project savings summary for addition of variable frequency drives (VFD) for the main exhaust fan and dryer combustion fan

Measure No.

ECM-1

ECM-1

Total

Measure description

VFD for exhaust fan motor

VFD for dryer combustion fan

Electric

Demand (average kW/mo)

239.7

33.5

273.2

Energy (kWh/yr)

2 273 381

97 509

2 370 890

Demand savings (US$/yr)

16 868

2361

19 229

Energy savings (US$/yr)

82 319

3531

85 850

Total electric savings (US$/yr)

99 187

5892

105 079

Natural gas

Energy (Gj/yr)

10 170

1563

11 733

Total gas savings (US$/yr)

53 766

8266

62 032

Mainenance

(other)

Electric (US$/yr)

2000

2000

Maintenance (US$/yr)

8000

1000

9000

Payback

Total cost savings (US$/yr)

162 953

14 158

177 111

ECO cost (US$/yr)

990 570

48 828

1 039 398

Simply payback

6.1

3.4

5.9

August 2015

|

World Coal

|

61