analyse the latest operation cycle. These

software tools make up Cat MineStar

Health for Longwall and are used at the

gate end PCs and on the surface.

In particular, these tools allow the

visualisation of all longwall

subsystems and equipment – from

shields, armoured face conveyors

(AFCs), shearers or ploughs to chain

tensioning and boot end systems –

with regard to machine variables and

parameters. Health for Longwall offers

live views, generates daily log files for

analysis and plays back operational

data. Using the Cat Data server for

longwall (VDataSrv), the mine team is

able to provide all relevant live data at

five different software interfaces (OPC,

Sql, UDP, EIP and a web server) within

the mine local area network (LAN),

giving the mine further usage of the

data within its network. Health for

Longwall includes VlongwallDataBase

as a tool for longtime data storage and

reporting of almost all data sets

generated onboard. This allows the

mine operators and the supporting

dealer to run continuous reports and

analysis on the machine health,

supporting proactive maintenance

work at the face. Health for Longwall

vibration analysis offers continuous

online vibration monitoring. Use of

this tool allows the detection of all

abnormalities in the longwall system

drive train, such as bearing defects or

increases in wear.

Serving production

expectation

SBA and Navigation features help

facilitate smooth production at a

consistent rate and allow the mine to

achieve a high and constant

coal‑clearance capability. Downtime of

equipment is reduced and inefficient

use of uptime is avoided.

The use of SBA requires strict

discipline, a cultural shift and a

concerted effort by management to

steer the change. However,

considering that the results can be

double-digit productivity increases,

these investments in time and effort

pay off quickly.

When Caterpillar’s SBAwas

implemented at a mine in Australia’s

Hunter Valley in 2004, the success was

immediately apparent. In the first

calendar month after introduction,

productivity increased more than 10%

and it has remained at a consistently

higher level since the introduction of

SBA.

Pre-SBA production averaged

1892 tph, whereas the average

production rate after SBA introduction

was 2315 tph. Moreover, since the

installation of SBA, the EL3000 has

been the highest-producing shearer in

Australia. In 2008, four of the top five

producers in Australia were using

Caterpillar EL3000 shearers with

state-based shearer automation. In

spring of 2014, Caterpillar had another

customer in Australia exceeding

planned production month by month.

The utilisation of the

fully‑automated shearer is now

consistently reaching more than 94%

with no input from operators. This

number is expected to reach 100% as

operator confidence in the automatic

steering system grows.

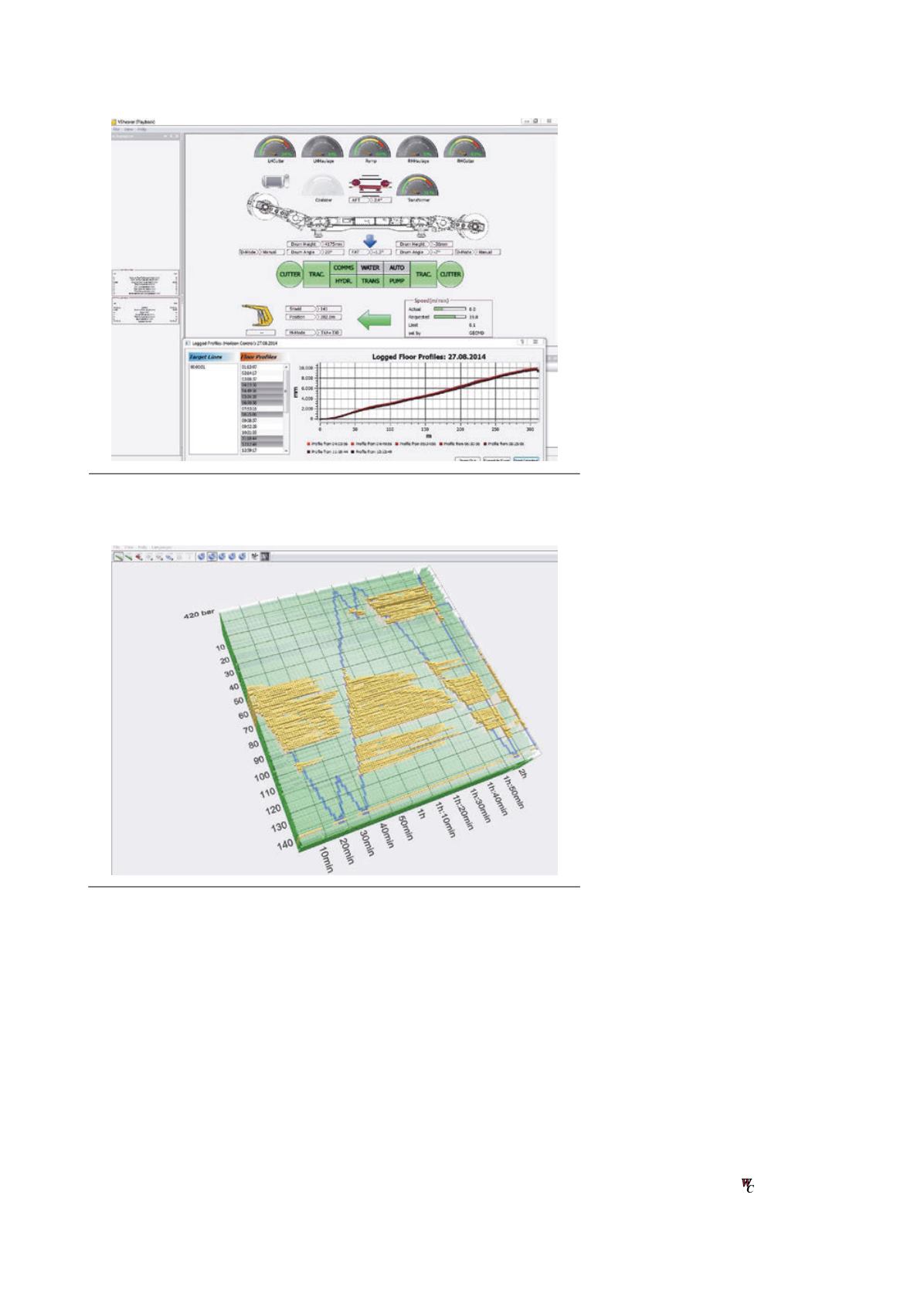

Figure 6. Cat MineStar system VShearer (shearer visualisation program) allows users

to define extraction profiles and provides the operator with a realistic view of the actual

pan profile.

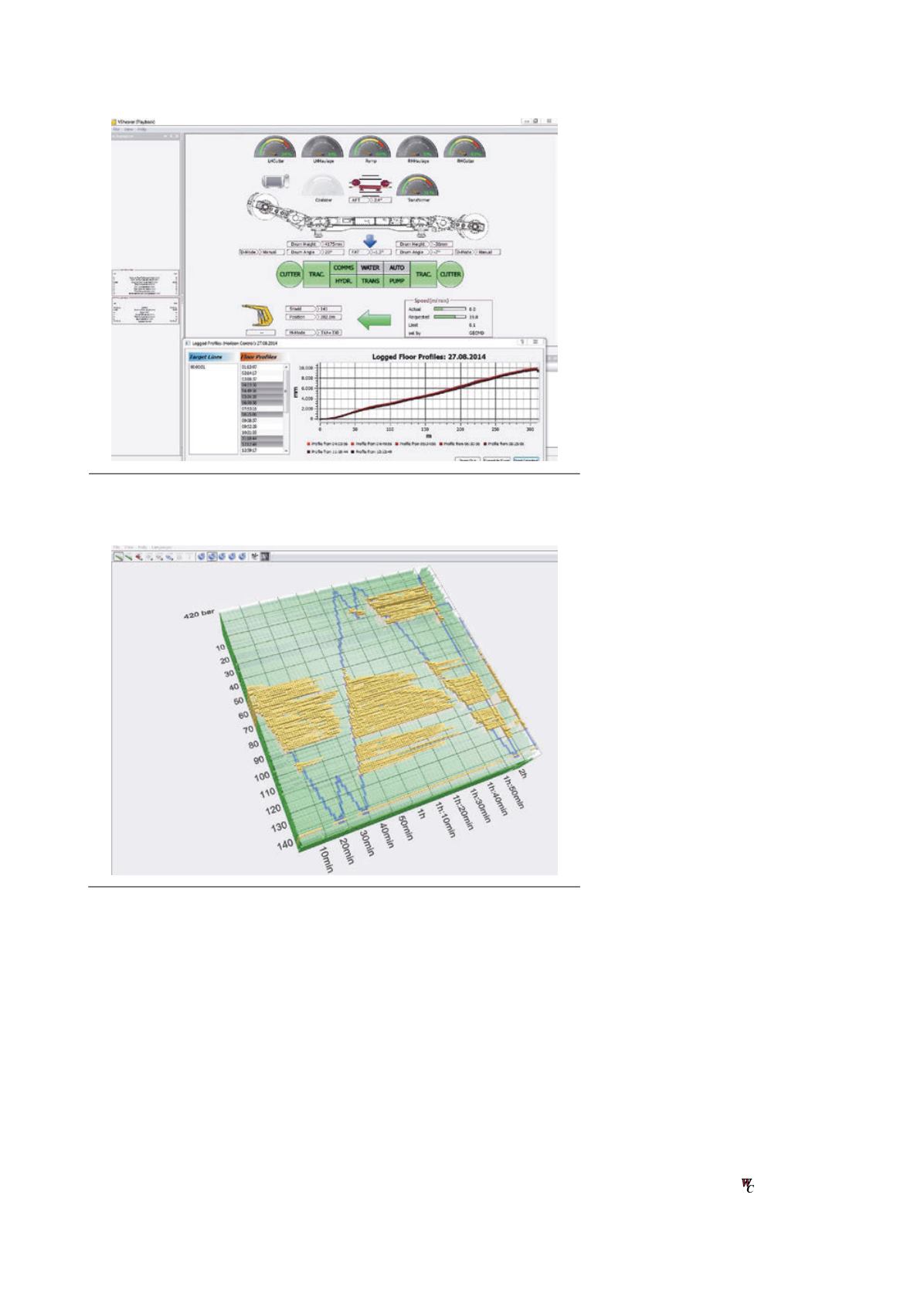

Figure 7. Cat MineStar system: VGraph3D providing several 3D waterfall plots for

review and predictive analysis showing e.g. set pressure or other parameter plotted

over time and face width.

58

|

World Coal

|

August 2015