Does automation mean

complexity?

Once the system is commissioned,

running in automated mode is simple.

The motor’s start sequence is a

two‑button operation on the handheld

remote and it only takes two more

buttons to activate auto mode. The

shearer will then initiate the drummode

for the desired state and position the

drum using the calculated data. These

calculations are done onboard in the IPC

using IMU data, shearer position data,

measured and fixed dimensions of

shearer geometry, ranging arm position

and cutter drum diameter.

How to reach a higher

level of automation

To set up all of this automation

requires a basic understanding of the

longwall mining process and technical

expertise with regard to the

mechanical and electrical equipment,

as well as the electronics. Usually,

personnel onsite are already familiar

with most of this equipment from their

current operations; however, they are

often eager to take their knowledge to

the next level. These personnel must

be trained to use the new technology,

but companies also need to roll out a

new culture for automation to take

hold. Automation needs to be

understood as something that enables

and supports existing workers, rather

than a potential cause for displacement

of jobs. If anything, increased

production will ultimately increase the

workload onsite, even if the tasks are

different with an automated system.

To set up the system into higher

level automated modes, Caterpillar

offers comprehensive tools to allow the

operator or the crew to define the

requirements by use of intuitive menus.

Data handling (e.g. loading

parameter settings and state tables

onto the machine) is fast and easy.

Within a few weeks of implementation

(if not during the commissioning

phase) operators adjust the state tables

even once or twice a day without

complaint, easily finding the optimal

settings for the production cycle of the

longwall operation.

Caterpillar’s set of software tools

supports operators in their efforts to

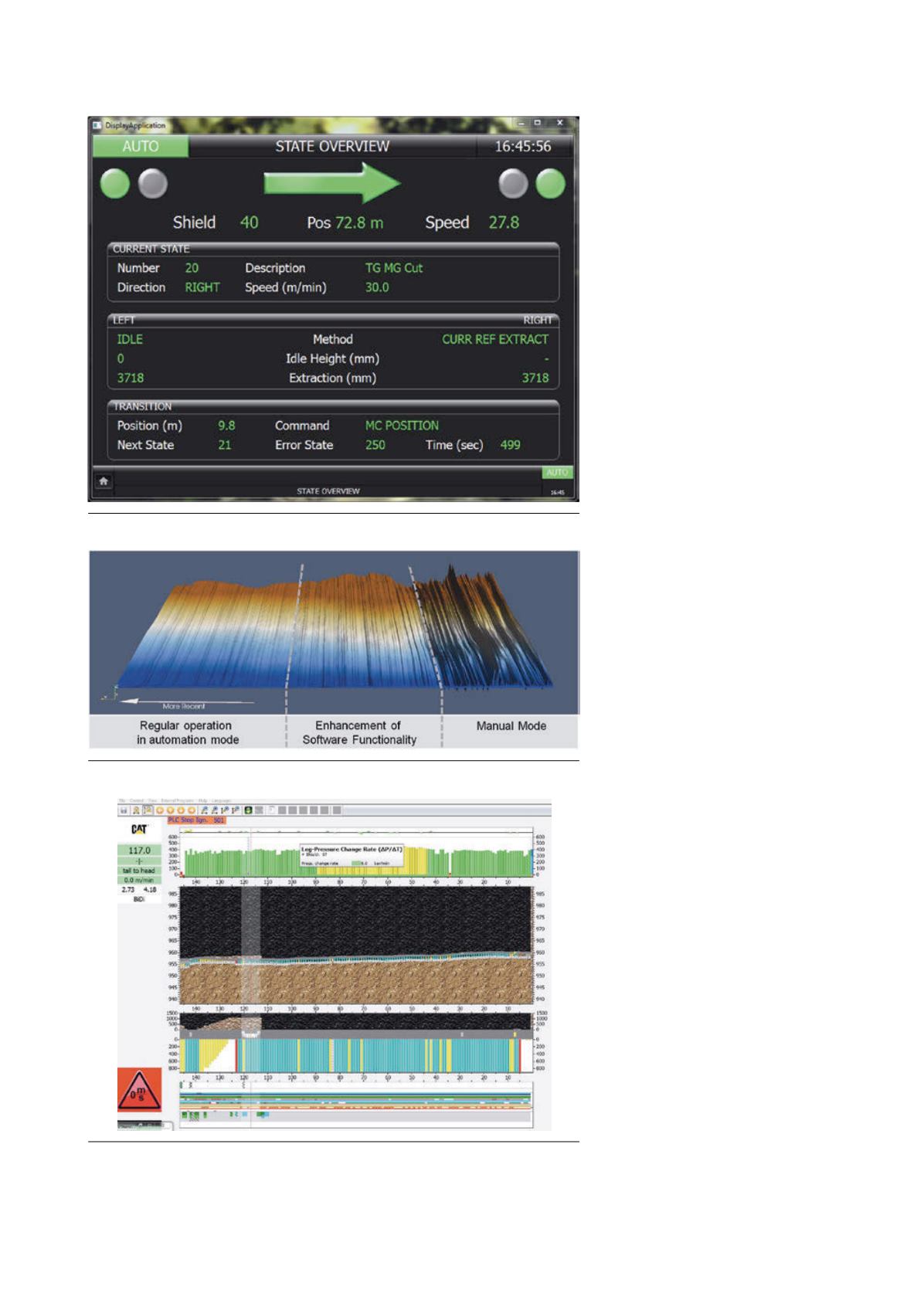

Figure 3. Example Cat Shearer main display during operation.

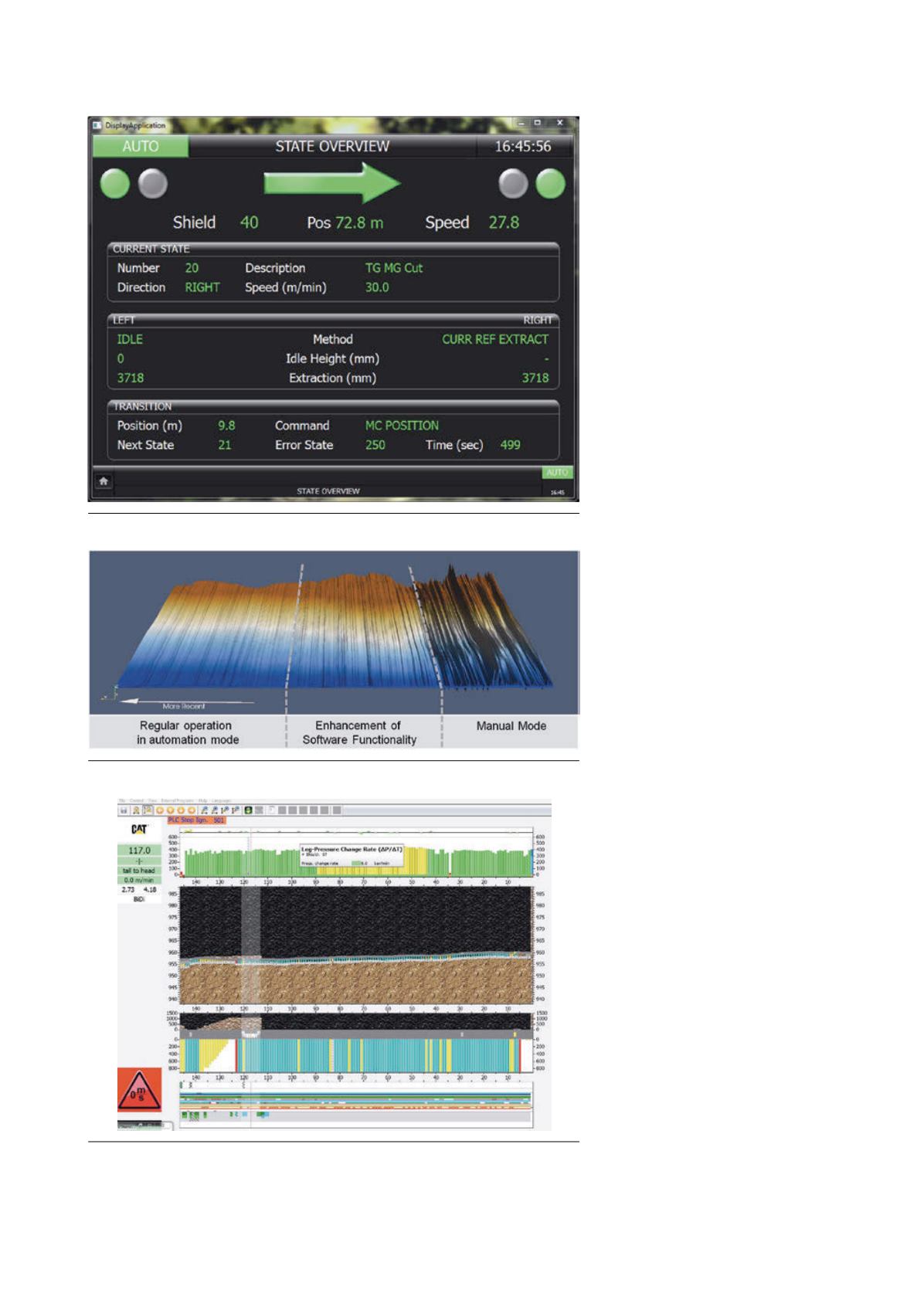

Figure 4. Improvement of profiling during implementation at example mine site.

Figure 5. Cat MineStar

®

system VShield (shield visualisation program) allows users to

define face advance profiles and provides the operator with a realistic view of the face

alignment profile.

56

|

World Coal

|

August 2015