modes. Users can define up to 500

states with actions and conditions to

be met before the next state is entered.

The system is also capable of defining

up to 40 zones along the face for each

of the zone-based parameters. This

allows mine personnel to determine all

possible variations in longwall

operation cycles.

History and technology

behind advanced

automation

Achieving automated horizon control

has long been a goal for the longwall

mining industry. There have been

systems developed for shearers that

use a reference cut in one direction and

extraction to a desired thickness in the

opposite direction. These systems have

been enhanced over time with onboard

calculations that take into account

machine and face angles. This helps

create greater accuracy in actual

extraction parameters, with various

methods of extraction depending on

the cutting sequences being employed

on the face.

At the turn of the century, modern

inertial sensor technology was

introduced to offer accurate

measurement of the face alignment,

horizon angles and pan profiles of

longwall faces. Originally derived

from gyroscope technology, inertial

sensor developments became a focus

for Bucyrus and DBT Group, both of

which were subsequently purchased

by Caterpillar. The inertial sensor

technology now used by Caterpillar

has been developed by a third party

supplier, while the associated software

was developed by Caterpillar over the

past 14 yr.

The company’s proprietary system

has been continually improved since

its implementation and saw

improvements to the software,

hardware and monitoring systems

with integration into the Caterpillar

visualisation suite of programmes as

part of Cat MineStar Health.

Hardware

Caterpillar offers two inertial sensors

to use as inertial measuring units

(IMUs). These units have proven their

capabilities in underground longwall

mines in Australia. They are classified

by accuracy, the ability to detect north

and the ability to process data

onboard. Each unit is configured to

operate within the system, while

customers choose whichever unit best

meets their needs.

Software

As part of the Navigator system, there

is a processor (IPC) on the shearer to

collect, process, calculate and

communicate data within the shearer

EIP control system, as well as both to

and from the gate end computer. Face

and horizon profiles are generated by

the IMU, through the IPC to the

visualisation software (VShearer, part

of Health for Longwall) at the gate

end. With this system, there is no

need to transfer data to a surface

server for processing, while all

communications are carried out

between the shearer and gate end

visualisation PC.

The ranging arm and shearer

positions are calculated by the

programmable logic controller (PLC).

The IPC performs the automated

steering (including state automation)

and sends haulage and ranging arm

commands back to the PLC.

Accuracy

The latest information received from

an advanced automation control

longwall operation in

New South Wales, Australia, shows

that accuracy has been measured to

within 50 mm. The original target was

to be accurate to within 75 mm;

however, some enhancements to the

software have resulted in greater

accuracy.

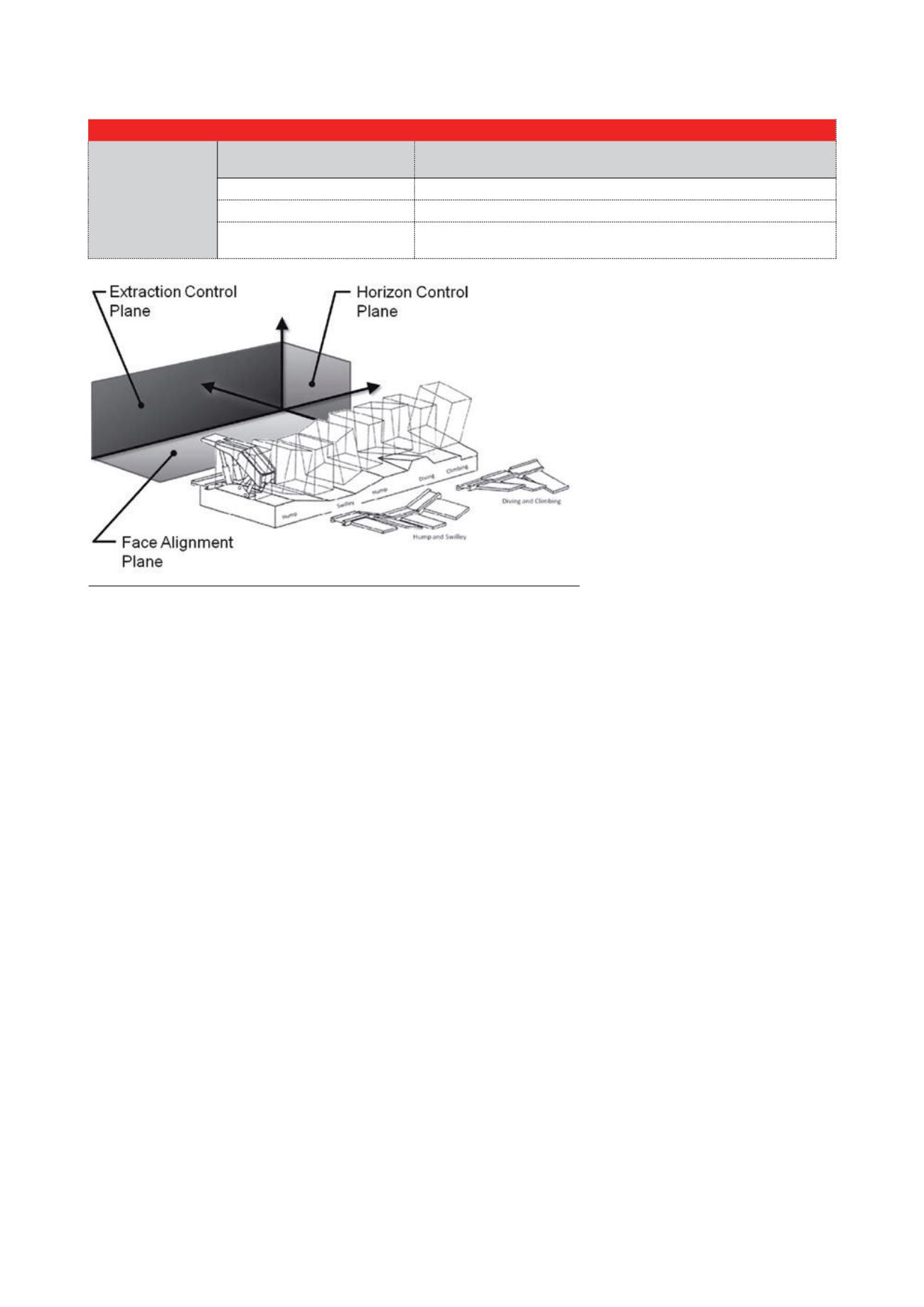

The graphic in Figure 4 shows the

change in the profiles over three

months during implementation of

shearer automation at a mine site. The

degree of automation was increased in

two steps and the period of manual

override constantly reduced.

Table 3. Advanced Automation Control: the highest level of automation functions for a longwall shearer

Advanced automation

control

Basic automation 1+

Advanced automation of high accuracy using inertion navigation: PLC, IPC and

INU (accuarcy < 20 mm along the machine length)

Advanced geometry/trigonometry For 3D navigation

Floor profile/arm algorithms

For 3D navigation

Interface to longwall

navigator/landmark

Enables integration of third party navigation system with landmark interface

Figure 2. Horizon control, extraction control and face alignment are the main features

provided by Cat LongwallNavigator.

54

|

World Coal

|

August 2015