face without opening flameproof

enclosures.

Intelligent software

modules

Caterpillar distinguishes between

different levels of shearer automation,

from basic to advanced.

Each of the company’s shearers is

equipped with a basic automation

package. This package allows the

machine to be operated by remote

control and to switch all equipment

safely while monitoring the operation.

This package also includes some

automation logic that can reduce

overload situations, as well as some

diagnostic tools for troubleshooting

and problem‑solving.

Alternatively, Caterpillar offers two

more complex automation packages:

automation control and advanced

automation control.

Automation control includes

important features, such as extended

gate end communication, which

provides data exchange with other

longwall components. This automation

level allows the ranging arms to be

operated in a high‑quality closed‑loop

operation for precise steering. It also

provides a collision avoidance function

to prevent collision between the

shearer and the shields operated by a

Cat PMC‑R.

The most important feature is

state-based automation (SBA). SBA

allows definition of the full cutting

cycle of the machine along the face for

both cutting directions between

maingate and tailgate, as well as the

cleanup operation at the gate ends. It is

important to specify automation

parameters, including cutting height,

speed and cutting mode, all of which

can be defined in as many as 40

different zones along the face. This is

called zone‑based automation.

Caterpillar has created several

preset cutting modes that can be

chosen in each automation state.

The advanced automation control

package includes a feature called

LongwallNavigator, which combines

Caterpillar software tools in the gate

ends and in the shield controllers into

one package that offers advanced

geometry and trigonometry

calculations for full 3D navigation, as

well as an advanced floor profile

calculation and a high level of sensor

technology.

These technologies make it possible

to achieve horizon control, extraction

control and race alignment. Extraction

control allows the machine to follow

defined floor and roof profiles along

the face, following any given coal seam

undulations for optimal extraction and

production. At the same time, horizon

control guides the machine to follow

the seam undulations in the direction

of the machine’s advance. Face

alignment keeps the face straight for

consistent production and minimal

wear of the conveyor system.

All these automation features

support both uni‑directional and

bi‑directional mining methods.

Caterpillar can also support additional

customer-specific automation

processes, including complex longwall

top coal caving (LTCC) operation in

combination with fully‑automated roof

supports. In this case, the PMC Evo‑S

control system provides continuous

information to the PMC‑R roof support

controls to steer the face conveyor

push operation.

SBA is an efficient tool for defining

and controlling complex automation

cycles. It allows the shearer to operate

precisely according to the operator’s

defined production process, including

directions, speeds, arm heights, cowl

positions and ranging arm control

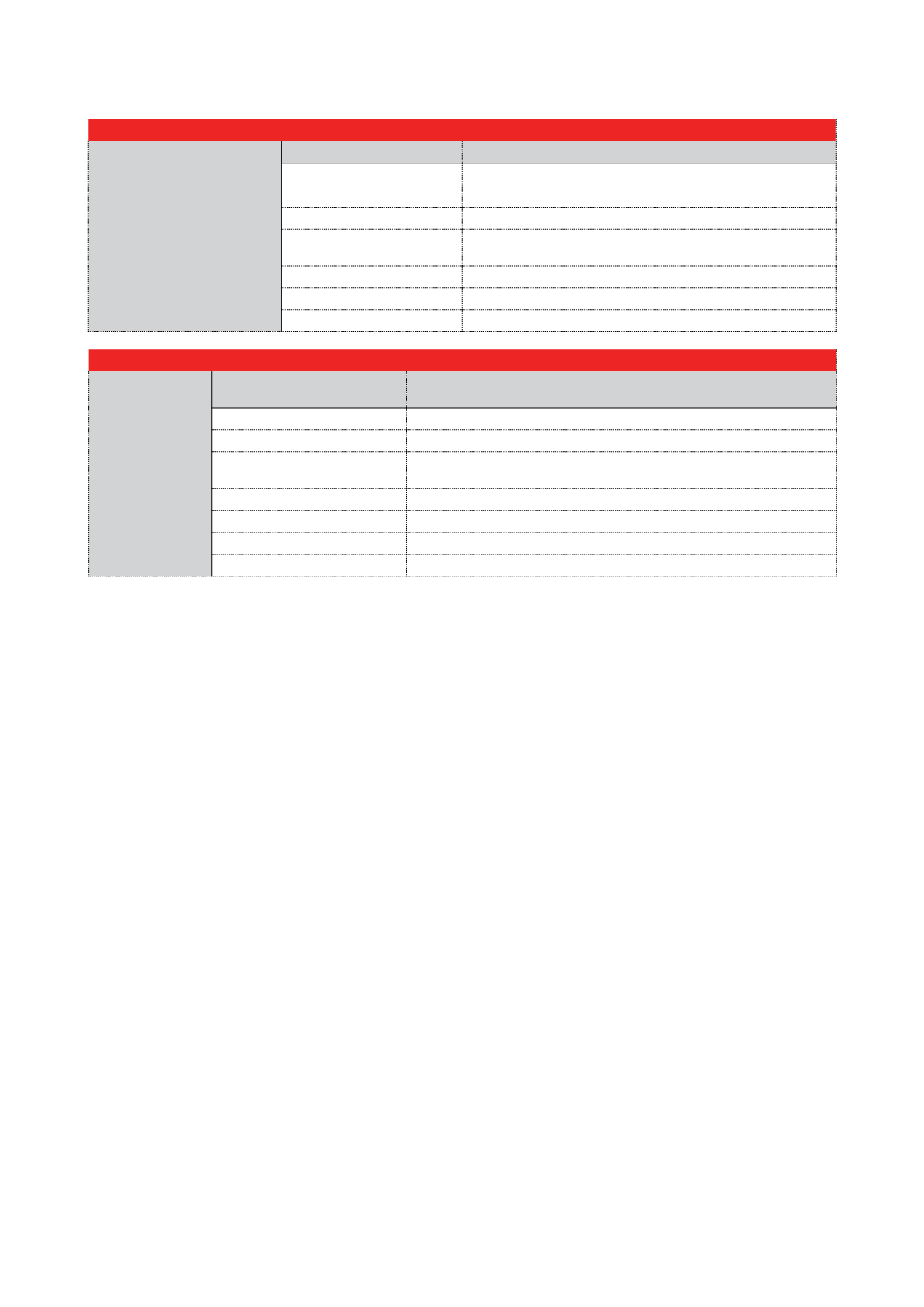

Table 1. Basic control functions of a longwall shearer

Basic control

Manual operation

Provide manual operation: only PLC

Shearer radio control software Allow miner to operate the shearer via radio control

Standard display

Provide the visualisation of the operation related values and parameters

Self monitoring

Permanently check all operation related components and functions

Safety functions

Tilt sensor monitoring in radio handheld, monitoring of the radio

connection, etc.

Speed limiting

Definition of up to 10 speed zones along the face

Display/HMI tools

For miner-machine interaction

Cutter motor feedback

Controlled breaking of haulage speed depending on cutter load

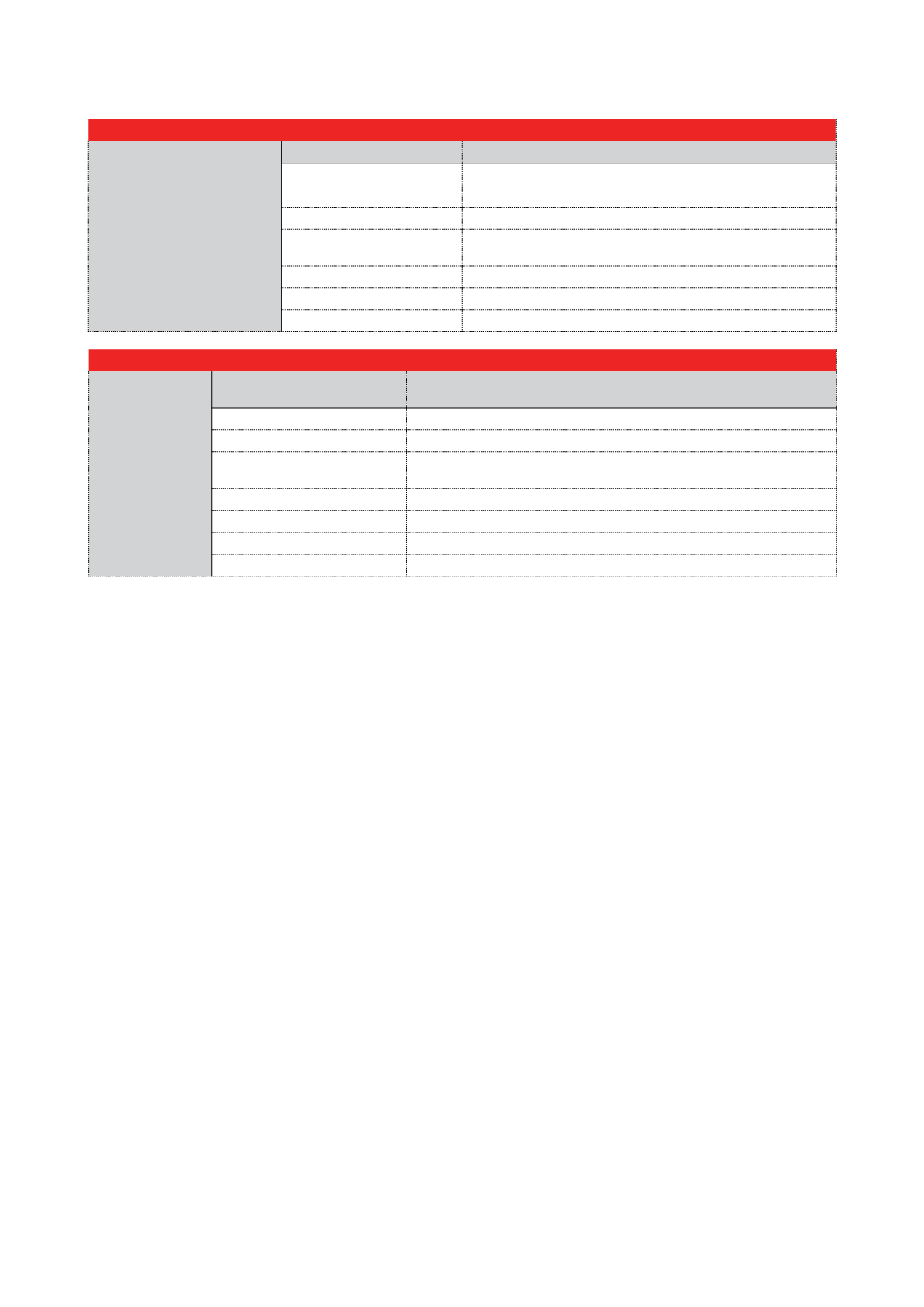

Table 2. Automation Control: the next level of automation functions for a longwall shearer

Automation control

Basic control +

Advanced automation of low accuracy using inclinometers: PLC and IPC (accuracy

< 100 mm along the machine length)

Gate end communication

Provide data exchange with other longwall components

Collision avoidance

Prevention of collision between shearer and shields

State-based automation (including

zone-based parameters)

Definition of automation parameter in zones along face: up to 40 different zones

Ranging arm closed-loop control

For exact ranging arm position control

Cutting modes

Allows to operate the shearer via radio control

Common automation features

Cutter motor feedback, etc.

Onboard system diagnostics

For easy troubleshooting

52

|

World Coal

|

August 2015