performance. In late 2012, the plant

hired Jenike & Johanson (J&J) to

evaluate the transfer chutes. J&J

visited the plant to review the transfer

chutes and the problems.

Riad Dandan from Dominion’s

headquarters in Richmond, Virginia,

was involved throughout in

identifying the problems and

providing project direction.

Analysis and

corrective plan

Based on the initial review of

problems with these transfer chutes,

J&J recommended conducting flow

properties testing of the coal handled

at the plant. The plant had multiple

coal suppliers. The moisture content

of the coal changed quite a bit,

depending on the time of the year.

Because of this, it was decided to test

samples from a few different

suppliers and to run the tests at three

different moisture contents to cover

the range of possible operating

conditions. Various chute surfaces

were tested to determine the most

suitable chute liner surface from a

reliable material flow perspective.

Test results showed that increases

in the moisture content of coal made

the chute surfaces significantly more

frictional. This meant that, unless

sufficient slope was provided, coal

flow velocity would decrease and

could cause material stoppage and

buildup on the chute surface. Any tall

drops would result in high impact

pressures. Tests showed that

high‑impact pressures would require

considerably steep chutes to ensure

that the coal stream would not come

to a stop after impact with the chute

surface. Test results also provided

quantitative values of the chute

angles required to achieve reliable

flow. Based on the test results,

SA1750CR, a chromium carbide

overlay on steel provided by

SAS Global Corp., was selected for

the purpose of lining the modified

chute arrangements.

The information obtained from

this testing was also used to

determine the input parameters

required for Discrete Element

Modelling (DEM). J&J’s proprietary

DEM software was used to perform

the analysis. DEM is a numerical

technique used to simulate the

motion or flow of a collection of

particles. It uses laws of motion to

calculate the total force experienced

by individual particles in a bulk

material to determine their

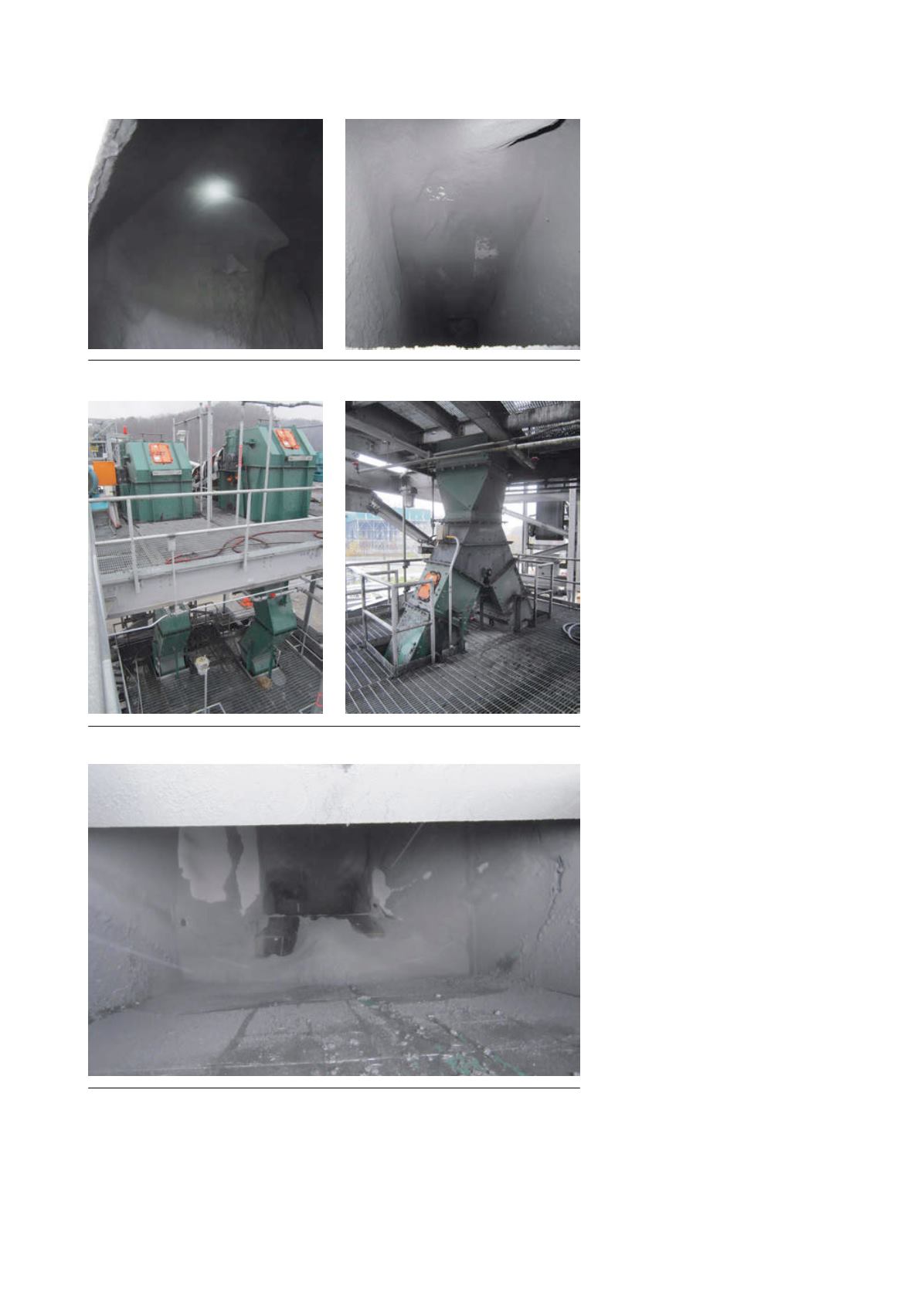

Figure 3. Buildup inside discharge chute for crushers.

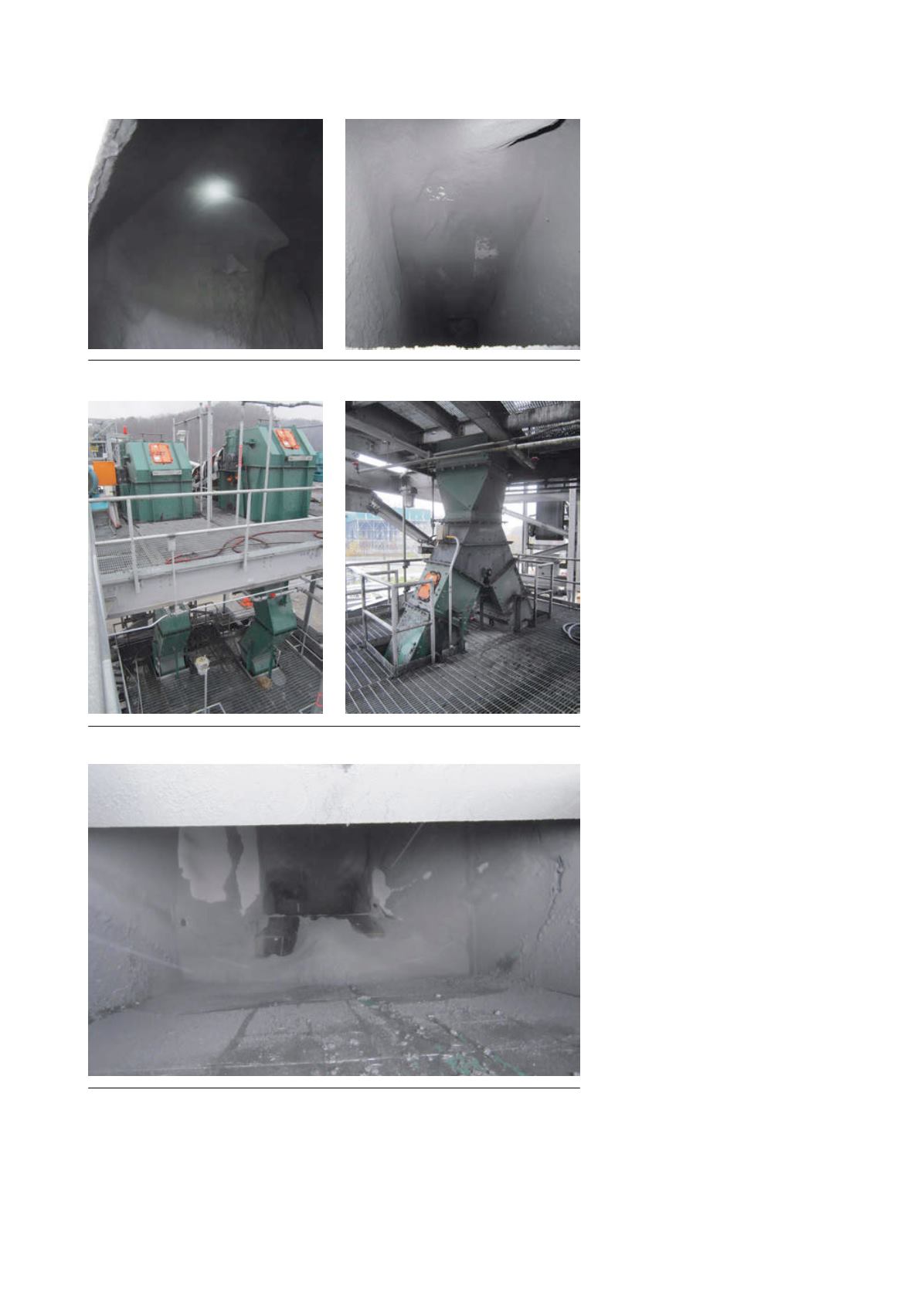

Figure 4. Original chute arrangement from belt RC3 to belts RC4 and RC5.

Figure 5. Coal buildup inside chute arrangement from belt RC3 to belts RC4 and RC5.

46

|

World Coal

|

August 2015