the form of a stockpile using an

automatic stacker. Then, as needed,

blended coal is reclaimed using an

automatic reclaimer and conveyed to

two surge bins. These surge bins

discharge coal into two hammer‑mill

crushers: crusher 1 and crusher 2.

Each crusher has a normal throughput

rate of 750 tph. The crushed coal then

discharges into the crusher discharge

chutes beneath each crusher. Each

crusher discharge chute has a diverter

arrangement that can discharge

crushed coal on either belt conveyor

RC2 or belt conveyor RC3. The

inclined conveyors RC2 and RC3

transfer coal to inclined belt

conveyors RC4 and RC5 using two

chute arrangements with diverter

gates. The conveyors RC4 and RC5

transfer coal to the tripper floor of the

boiler silos.

The transfer chutes and

flow issues

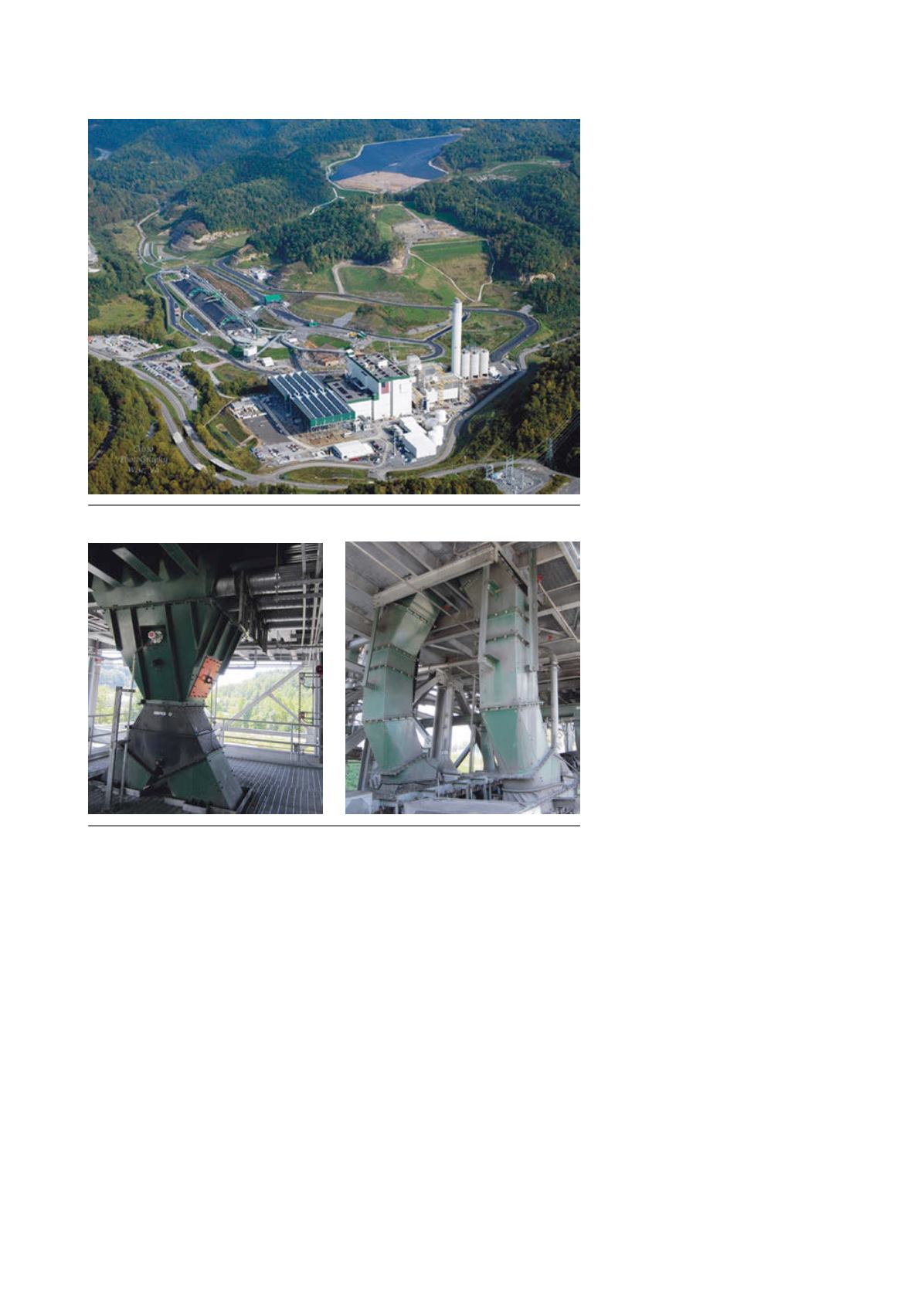

Figure 2 shows the original discharge

chute configuration for crusher 1. The

discharge chute for crusher 2 had

similar arrangement.

The original chute arrangement

had a pyramidal collection hopper at

the top with 10 ft 7 in. long by

9 ft 5 ½ in. wide inlet with 24˚ and

21˚ hopper walls (angles measured

from the vertical). This arrangement

resulted in about 31˚ valley angles.

The bottom square opening size was

only 2 ft. 5 ¼

in. The collection

hopper was lined with 304 stainless

steel plate. Below it, a diverter

arrangement directed coal onto

either RC2 or RC3 belt. Both belts

were 42 in. wide, with 35˚ equal

length troughed idlers. The belt

conveyors ran at 578 ft/min.

Plant personnel reported that the

crusher discharge chutes experienced

material buildup (Figure 3), especially

when handling fine and moist waste

coal. If unattended, the material

buildup led to plugging of the chutes.

When plugging occurred, manual

intervention was required to restart

flow.

Figure 4 shows the original chute

arrangement for belt conveyor RC3;

chute arrangement for belt RC2 was

similar. Belts RC4 and RC5 are 48 in.

wide with 35˚ idlers, and run at

578 ft/min. Conveying direction of

belts RC4 and RC5 makes a 113.3˚

angle (measured clockwise) with the

conveying direction of belts RC2 and

RC3. These chutes are nearly 50 ft tall.

The chute arrangement had several

sections, including a diverter gate to

direct discharge coal on either belt

conveyor RC4 or RC5.

Plant personnel reported that these

chutes experienced material buildup

(Figure 5), especially when handling

fine and moist waste coal. These

issues mainly occurred in the upper

part of the chute arrangement that

had multiple zig‑zag shaped sections

and a narrow diverter arrangement. If

unattended, the material buildup led

to plugging of the chutes. When

plugging occurred, manual

intervention was required to restart

flow. Operators needed to use

hammers, poke rods and water lances

to clear buildup.

These transfer chute arrangements

were not suitable for handling fine

waste coal with high moisture

content. Thus, when such coal passed

through these handling systems, flow

problems occurred. Virginia City

Hybrid Energy Center decided to

modify the transfer chute

arrangements to improve

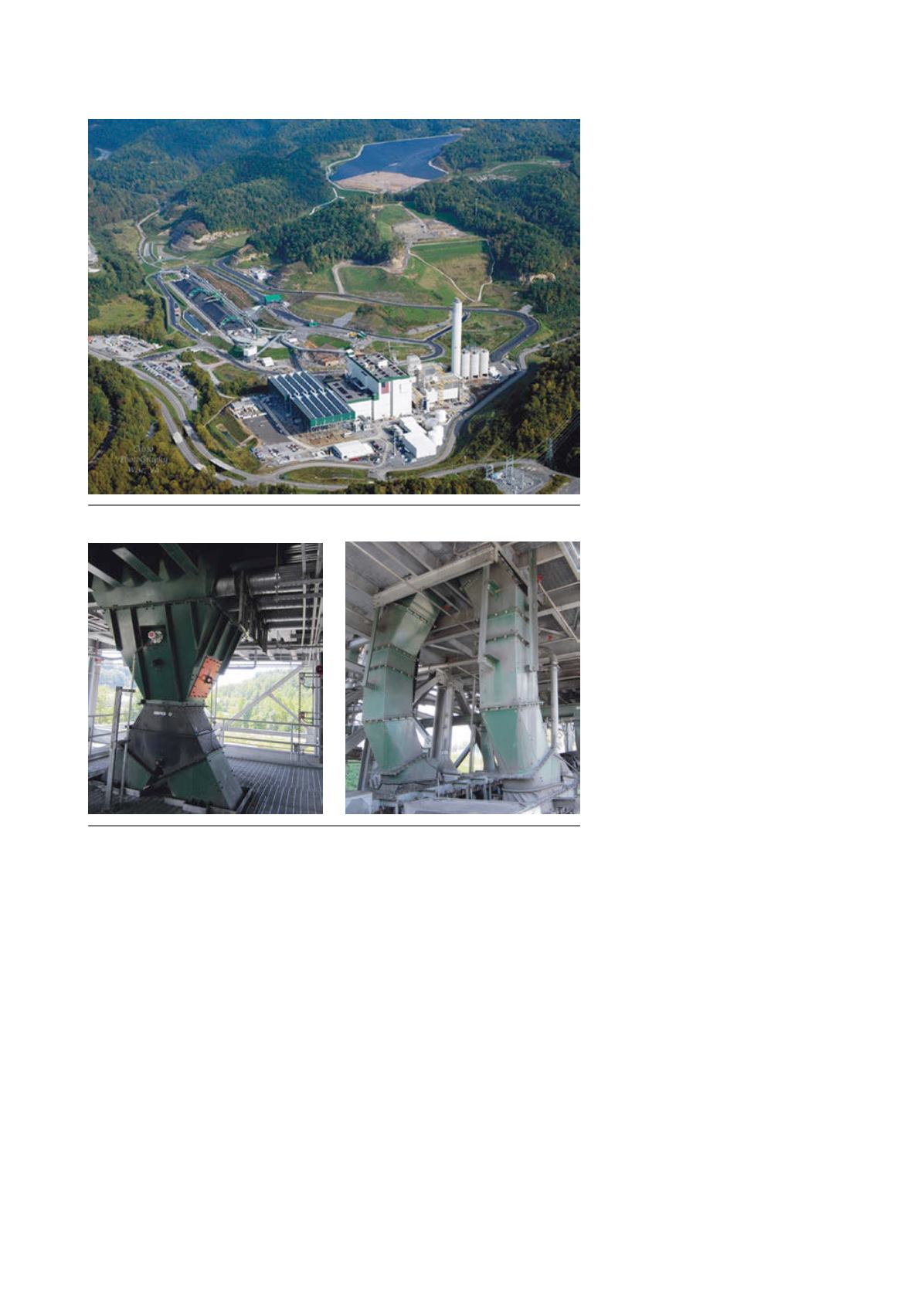

Figure 1. Virginia City Hybrid Energy Center.

Figure 2. Original discharge chute for crusher 1 – top section (left) and bottom section

(right).

44

|

World Coal

|

August 2015