60 |

Oilfield Technology

June

2015

process, the industry has an excellent understanding of what needs to

be done; this is the 80%. The ‘other 20%’ is discovering ways to further

support the various aspects of well construction in detail in order to

innovate newways to drive efficiencies and cost savings.

Therefore, the 80/20 rule is applied to the unconventional shale

plays, innovation with respect to holistic reliability in the space of the

‘other 20%’ is critical in today’s low oil price environment.

Innovationof thewellhead

One key component on every well drilled is the wellhead. It is a vital

pressure‑containing component at surface that can oftenmake

operational processes more efficient and flexible. By nature, horizontal

wellbores are deviated, causing fluids and cement tomigrate to the low

side of the hole, resulting in a less than optimal distribution downhole.

Internal components, such as a rotatingmandrel hanger, will allow the

casing to be rotated through the heel of the lateral as well as ensure the

production casing runs the full length of the lateral and achieves a proper

cement job. Once the casingmandrel is landed in the wellhead, slotted

mandrel shoulders permit cement circulation, removing the necessity to

wait on cement as with casing slips.

Other options that can drive operational efficiency are back pressure

valves (BPVs) and wellhead packoff systems. These can be installed

into the rotatingmandrel to provide a barrier for both the bore and the

annulus to secure the well at surface. This is especially important to help

increase operational efficiency, as walking drilling rigs often are planned

tomove off the current well and onto the next as soon as possible.

Another important wellhead component in the completion and

production process is the tubing hanger. Frequently after a well has

been hydraulically fractured and the well flowed back and cleaned up,

production will naturally flow for a period of approximately six months.

After this time period, production often requires installing artificial lift

and setting a packer downhole. A tension hanger is one easy way of

achieving this, allowing completions to set the packer and keep the

tubing string in tension. This will help prevent rod wear and provide a

standardised solution to the completions team, who is also likely focused

on boosting operational efficiency.

An example of advances made in the area of wellhead reliability and

functionality for unconventionals is Cameron’s advancedmulti‑bowl

nested diverter snap ring (MN‑DS) wellhead system. In this wellhead,

the production casing/tubing hanger is nested within the lower casing

pack‑off. It features a nested internally locked upper hanger that

reduces the overall height of the system for easier use with skidded rigs.

This hanger can be either a production casing hanger or a tubing hanger,

providing the option to complete as a one‑stage system if intermediate

casing is not required.

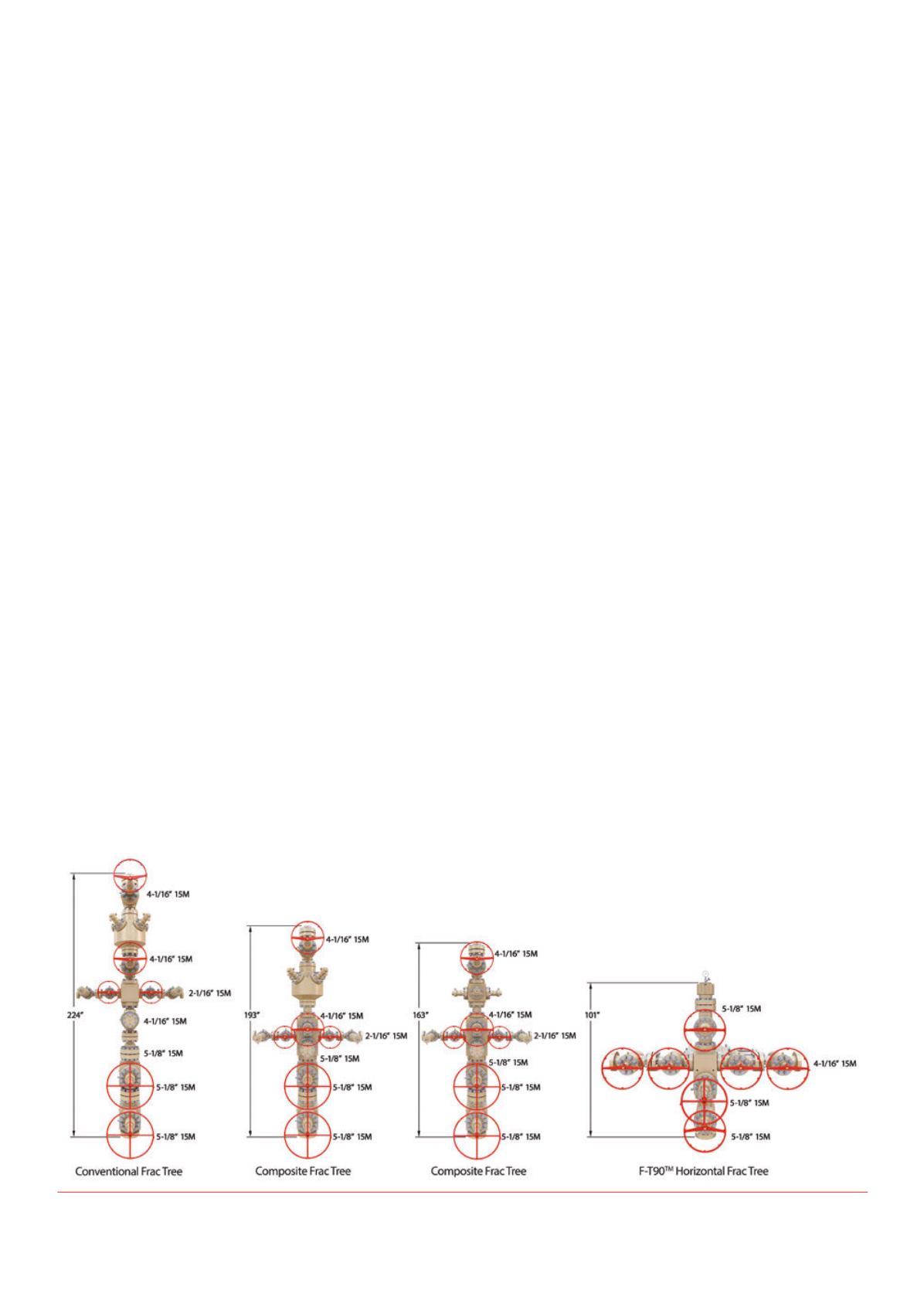

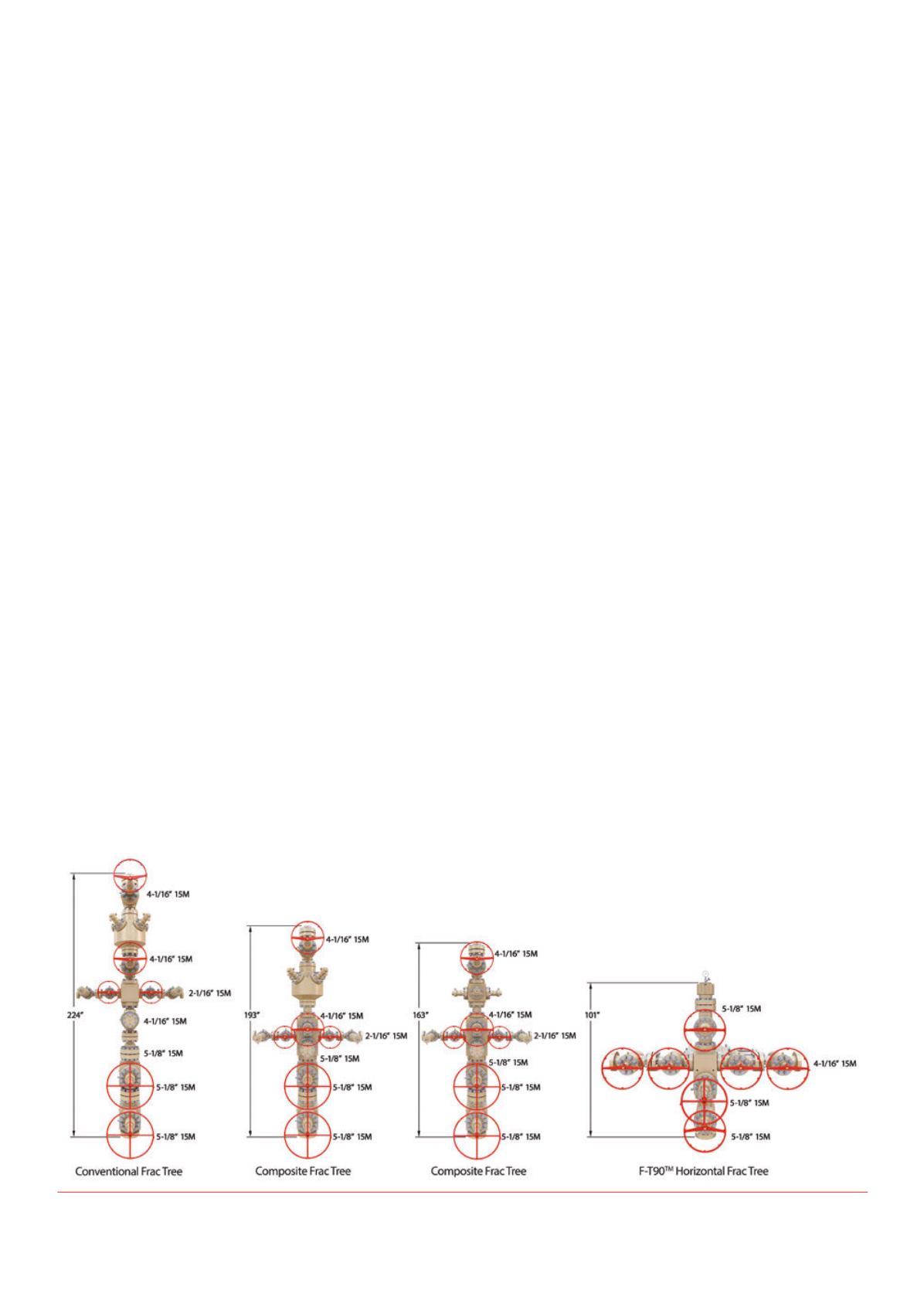

Innovationof the fracktree

As operators have adopted the factory approach to drive efficiencies in

batch drilling and completions, frack tree designs have evolved, moving

away from tall vertical conventional frack trees tomore compact designs.

A recent move in forward‑thinking innovation for unconventional

shale plays is Cameron’s F‑T90™ frack tree. It is the industry’s first

horizontal frack tree specifically suited for today’s factory approach to

multiwell pad drilling, batch completions, and simultaneous operations

(SIMOPS) applications. The F‑T90 is engineered 50% smaller and 25%

lighter than conventional frack trees while preserving the rigorous

durability and reliability required by the industry (Figure 1).

By taking the tall vertical configuration of the frack tree and turning

it horizontally, the industry is able to take advantage of this configuration

to reduce vibrational effects of fluctuating pressure caused by the

introduction of solids flowing through frack equipment, enhancing the

integrity of overall frack operations. The 90˚ goat head is located at the

end of the horizontal section, resulting in the distance acrosswhich the

bending loads act being less than half of that of a conventional stack‑valve

frack tree. Overall, its ultra‑compact footprintmakes installation easier and

reduces bending stress at thewellhead connection.

Frack service is just about as harsh as it gets, and with the adoption

of zipper fracking, frack trees andmanifolds are being exposed to

nearly continuous service, flowing and controlling high‑pressure,

high‑volume, abrasive/corrosive frack fluid for days and weeks. To

address these issues for continuous reliability, the frack trees incorporate

metal‑to‑metal seals, feature CRA inlay in seat pockets and ring grooves,

and use zero‑chamfer flowbores tomitigate turbulence that is known to

exaggerate erosion.

These features have proved beneficial in field application; there

will no doubt bemore developments as themission toward increased

reliability continues.

Innovationof frackfluiddelivery

One factor in the evolution tomultiwell pad drilling and batch

completions is the increased time that pressure pumping crews are

spending on the wellsite. Not long ago, service providers often spent

five to seven days fracking a single well with 20 stages per well, on

average. Nowadays, pressure pumping crews are spending 20 to 30 days

Figure 1.

Frack tree technological evolutionand innovation.