70 |

Oilfield Technology

June

2015

production become a social responsibility to address a growing

global demand.

While many companies are struggling to find markets for the

services they offer, Welltec® has continued to deliver through

this economic flux. The company’s stated goal is to go beyond

expectations by changing how the industry operates; specifically,

it provides operators new ways to carry out traditional jobs by

optimising processes and using light, yet powerful tools driven by

methods designed to improve efficiency, safety, and sustainability.

For the past 20 years, e‑line tools and interventions have been

shaping the industry, and the latest versions of these tools have

recently shown their worth to operators in the field.

Thebeginningof e‑line interventions

Nearly 20 years ago, the Well Tractor® was first deployed into

complex horizontal wells. At the time, this system represented a

paradigm shift for the industry as a small, lightweight intervention

method, run on e‑line, that could replace larger, heavier, more

intrusive and complicated methods. Upon its introduction,

the system provided reliable conveyance to supplement these

approaches, becoming a natural extension of e‑line. Tractors now

routinely complete thousands of jobs a year due to increased

efficiency, safety and lower cost to the operator.

An e‑line deployed, robotic device, the Well Tractor carries out

operations throughout the length of the wellbore regardless of the

deviation and extension. In particular, it is able to apply enough

force to push large toolstrings to the end of the wellbore and move

past washouts in open hole operations. The system universally

runs all third party systems, fitting hole sizes from 2.2 in. to 22 in.

It enables coiled tubing, e‑line, and even slickline operations,

providing cost-effective conveyance in all environments.

A significant advantage it provides is the ability to overcome

the challenges of highly deviated wells by driving tools all the

way to the toe of the wellbore without the use of additional fluids

introduced into the wellbore. The e‑line tool circumvents the high

costs associated with rigs and is able to mobilise more quickly,

run in and out of the well faster than alternative methods, and

mitigate HSE risks by requiring fewer people at the wellsite while

in turn allowing for more sustainable operations in terms of the

environment and asset management.

Sustainableoperations

This technology also enables an expansive portfolio of services.

Running solutions for deployment, mechanical, clean‑out, milling,

completions, RLWI, and diagnostics, the Well Tractor helps

operators realise the full benefits offered by e‑line tools, regardless

of their manufacturer. And if fluid transportation is required, the

system can also run on coiled tubing, extending its lateral reach

in horizontal, deviated, and extended reach wells. Its pulling force

works to mitigate traditional issues encountered, such as excessive

friction, limited reach and buckling.

Newtechnologydevelopments

Recent developments in tractor technology have led to the

Well Tractor Next Generation (NG), which incorporates a new

electronic/hydraulic design for increased speed and reliability. The

Well Tractor NG currently holds the world record for the longest

cumulative distance tractored on one job, conveying its payload for

423 723 ft offshore Norway. These new improvements have enabled

a shortened solution, the Well Tractor Compact Rig‑up (CR), which

can be configured to less than 10 ft. This new tool has been used in

several recent North Sea operations.

Casestudy1

A highly deviated, water injector well offshore Norway had a

leak in the tubing above the downhole safety valve (DHSV) that

required remediation. Due to a limited rig up height of only 42 ft,

standard equipment would be extremely difficult to use safely.

The Well Tractor CR was subsequently chosen for this problematic

situation.

On the first run, the Well Tractor CR conveyed a 40 finger

caliper into the well where it logged from 13 255 ft. Following the

successful logging operations, the client decided to set a plug just

above 13 255 ft, and the tool was used again. The CR even passed

power through to a third party setting tool that set the plug.

During these operations, the Well Tractor CR achieved

tractoring speeds of nearly 7000 ft/hr, showcasing the power of the

new NG technology. The optimised speed and reduced tool length

saved the client 3 ‑ 4 hours compared to other e‑line conveyance

solutions.

Casestudy2

In another well offshore Norway an operator needed to pull

a deep‑set plug in a well with >90˚ deviation. Conventional

solutions required leaving well safety valves open in order to

accommodate the length of the toolstring, an option the operator

would not consider. The challenge came from the combination

of the limited rig‑up height and the highly deviated well, which

would require high pull forces. The available rig‑up/rig‑down

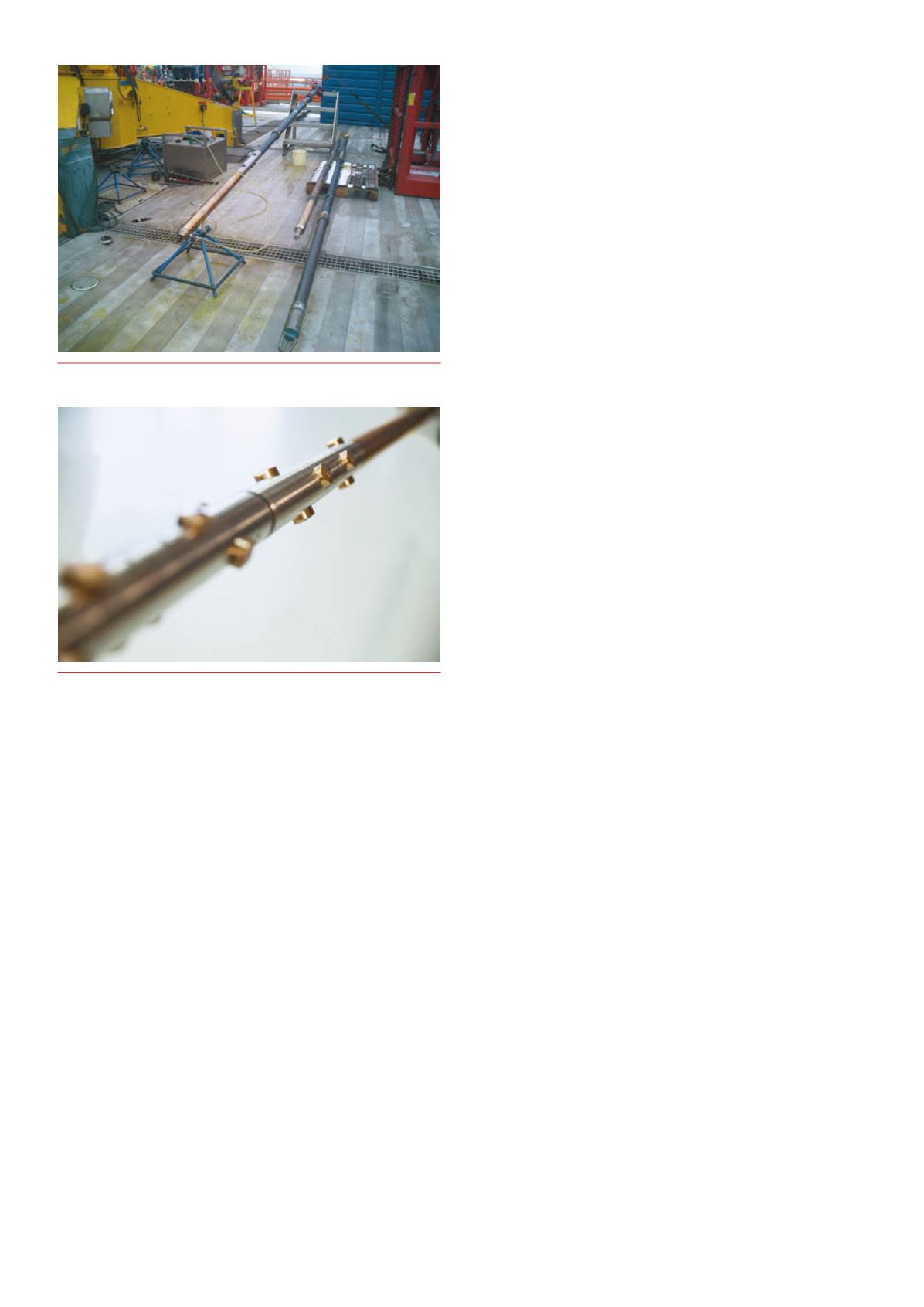

Figure 1.

The 4

½

in. Well Tractor tools get checkedat thewellsite.

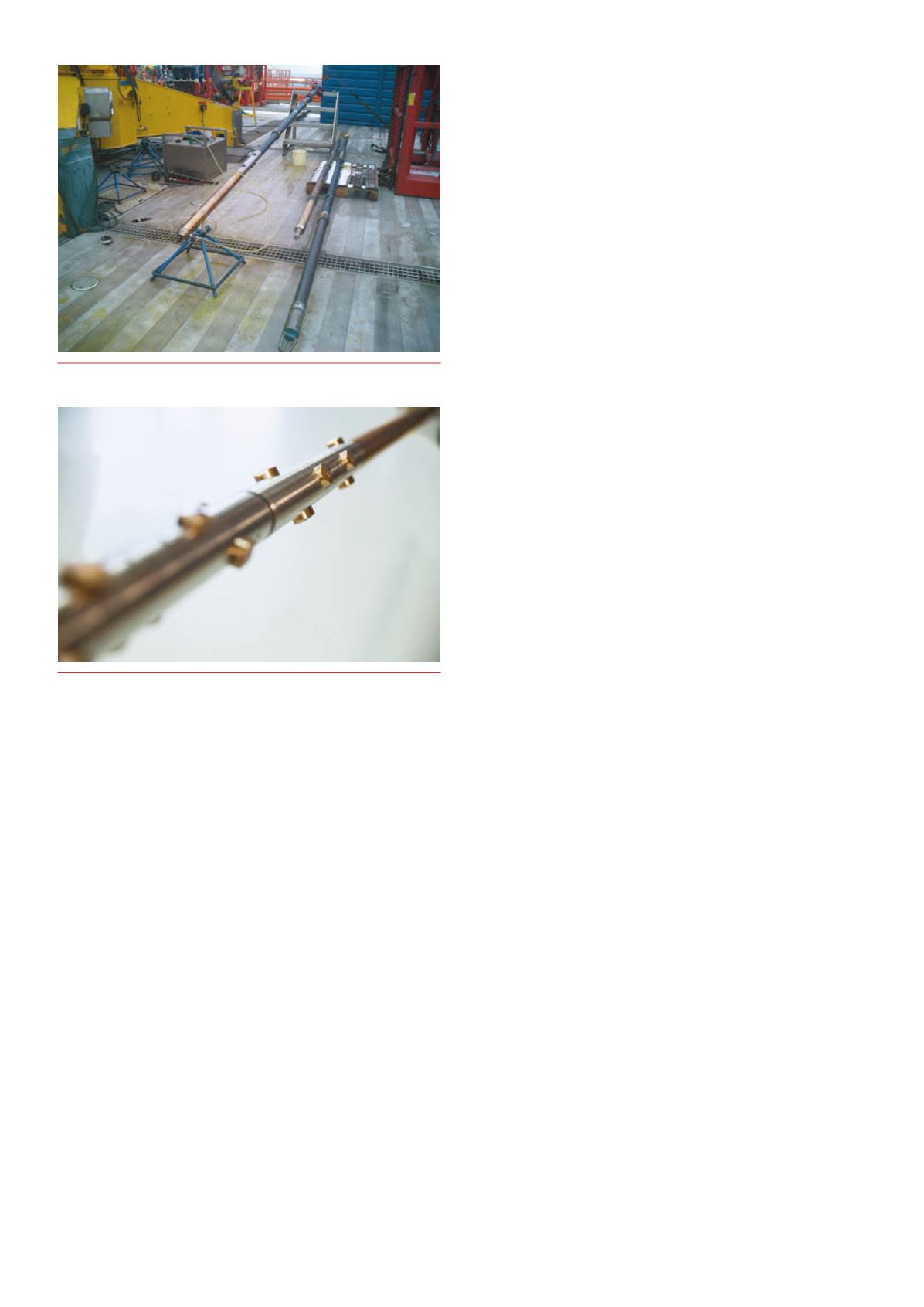

Figure 2.

The anchor sections of a slim, 2⅛ in. Well Stroker.