68 |

Oilfield Technology

June

2015

tailoring a carefully designed water composition appropriate to the

reservoir mineralogy. This involves changing the composition of

the injected water by removing certain salts and ions. Such water

treatment processes are very capital intensive. However, alteration of

wettability by using surfactant formulations in water flooding can be

relatively inexpensive to implement from a capital cost perspective

because the formulation can be stored and injected using mobile

skid units with simple injection equipment, which does not require

the high costs associated with facility development. Furthermore,

properly designed surfactant formulations have the ability to

function effectively in higher temperature and higher salt content

reservoirs. This is particularly relevant when discussing the use of

surfactant enhanced water flooding in the Middle East, where these

extreme reservoir profiles are common. A comprehensive portfolio

of surfactant formulations that are effective in favourably changing

the wettability of carbonate rocks at a wide range of temperature

and salinity conditions has been developed. Such formulations are

carefully evaluated in laboratory experiments, demonstrating their

potential use in improving water flooding performance in carbonate

reservoirs.

Labtestingandresults

One of the most important tests performed to characterise the

wetting behaviour of a surface is measuring the contact angle of

a water droplet on the surface. If the surface is oil‑wet, the water

droplet will not spread on the surface, and the contact angle (as

illustrated in Figure 2) will be greater than 90˚. On the other hand,

if the water spreads on to the surface, the measured contact angle

is less than 90˚; in this case, the surface is confirmed as water‑wet.

To test various surfactant formulations, an oil‑wet surface must

first be validated by placing a drop of brine (water with salt content

similar to formation water) on to a known hydrophobic surface. A

contact angle measurement of greater than 90˚ validates the surface

is oil‑wet. Then, a drop of the

surfactant formulation (solution

prepared in brine) is placed on the

same oil‑wet surface. An effective

wettability altering surfactant

should be able to enhance water

spreading on the surface, thus

leading to a contact angle lower

than 90˚. This phenomenon

is illustrated in Figure 2 for a

proprietary surfactant formulation

developed to effect wettability

alteration at a wide variety of

salinity conditions.

Additional tests are performed

by ageing calcite plates in crude

oil and exposing the oil‑wet cubes

to brine and a surfactant solution

in brine. While the plate exposed

to brine has significant amount of

oil sticking on to the surface, the one exposed to surfactant solution

looks drastically different (Figure 3). The surfactant effectively

spreads the brine over the oil‑wet surface, thereby changing the

initially oil‑wet plate to water‑wet, and effectively causing the oil to

bead up and release from the surface.

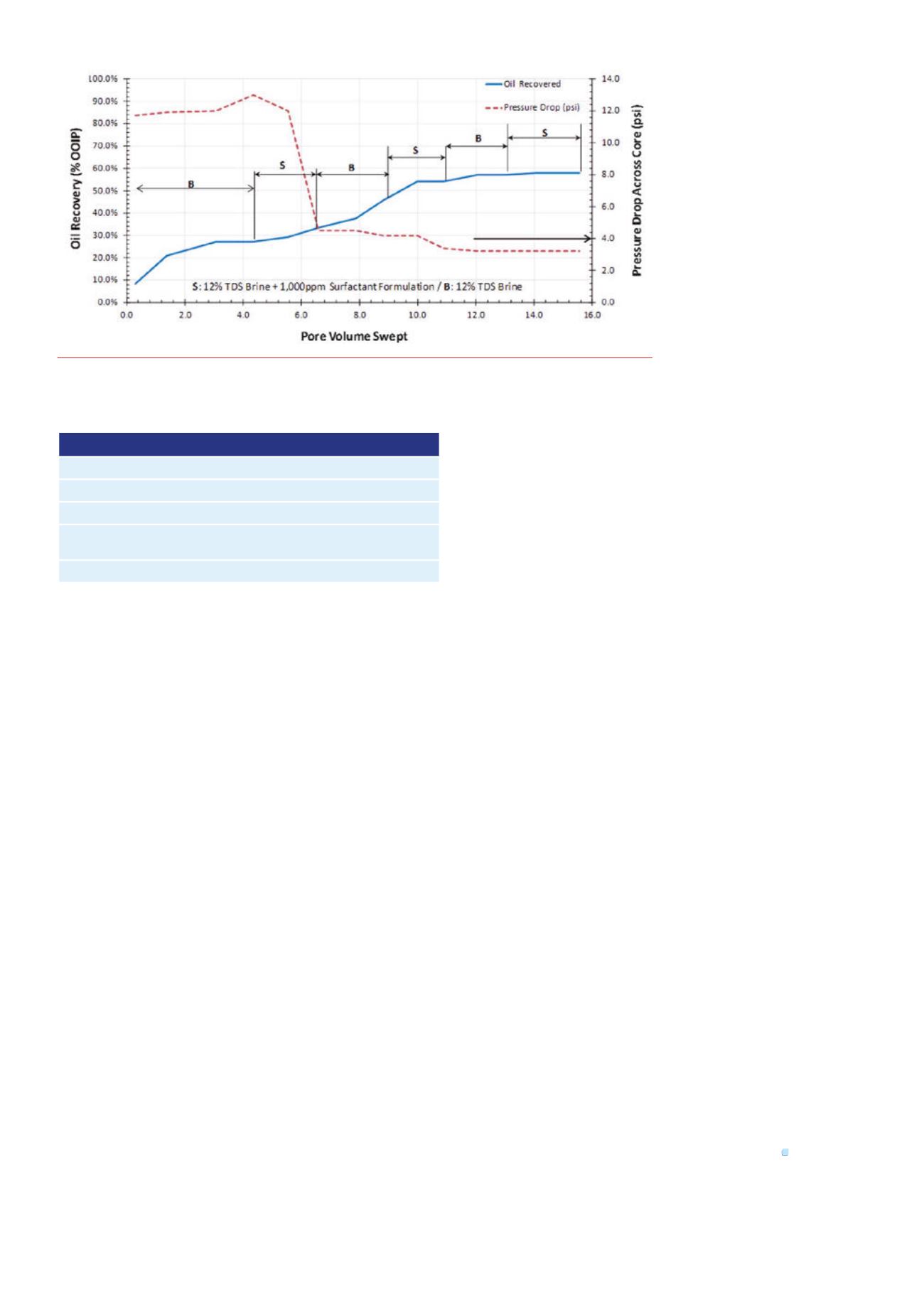

In order to validate the effectiveness of the surfactant

formulations to recover more oil from oil‑wet carbonate reservoirs

at representative reservoir conditions, core flooding studies are

performed simulating the oil recovery process from an oil bearing

carbonate formation. A sample result from one such experiment is

shown in Figure 4, where the oil recovered and the pressure drop

across a rock core during the flooding process are plotted compared

to the total rock pore volume swept by the flooding medium.

An outcrop Silurian dolomite core was used as representative

of a carbonate formation and Texas raw crude oil was chosen as

a representative crude oil from a carbonate formation. The rock

was first saturated with crude oil and then flooded with brine

until the oil cut in the produced fluid was less than 1%. This step

brings the oil saturation in the core down to residual saturation

to a water flood. Approximately 23% of the original oil in place

(OOIP) was recovered from water flooding. Alternate slugs of a

1000 parts per million (ppm) surfactant solution in brine followed

by chase brine were then flooded through the core. An additional

37% of the OOIP was recovered, leading to an overall oil recovery

factor of approximately 60% of the OOIP. The pressure drop across

the rock core also dropped significantly when the surfactant

formulation was introduced, indicating enhanced imbibition of

brine into the core.

Extensive lab testing has concluded that proprietary surfactant

formulations are compatible and can be optimised to meet a

wide range of carbonate reservoir conditions. Using specialised

formulations, tested and tuned according to reservoir conditions,

along with recommended reservoir injection strategies, the

performance of a water flooding process can be improved

significantly,

As the global population continues to grow, meeting new energy

challenges head on will remain a clear focus for operators. By

employing effective surfactant formulations, EOR processes can be

enhanced with minimal cost and increased simplicity.

Reference

1.

Schlumberger Oilfield Review, Summer 2007.

Figure 4.

Results fromsimulatingoil recoveryprocess inacore flood.Whileonly23%of theOOIPwas recoveredby

brine flooding (4 PV), introducing surfactant formulation in slugs resulted inanadditional recovery of 37%of the

OOIP. The pressure dropacross the core decreased significantlywhen the surfactant formulationwas introduced.

Properties of ideal surfactant formulations for wettability alteration

Effective wettablity altering agent at low dosages

Stability at challenging temperature and salinity conditions

Minimal water‑oil IFT reduction ‑ do not form viscous oil‑water emulsions

Minimal number of components with minimal chromatographic separation and

surfactant retention

No formation damage