64 |

Oilfield Technology

June

2015

operation withmore than 14 frack stages per leg. A four‑person crew

and one crane were used to install the pre‑assembled system in

3 hours per leg. The rig‑up time was seen at about half of that time, or

around 1.5 hours per leg. In addition to reducing the wellsite footprint,

the systemachieved a 50% reduction in the number of needed

hammer union connections.

As the number of needed connections is decreased, reliability

of the connections is increased and the drastically reducedmaze of

flowlines and restraints will have a positive impact on safety. It is the

collaboration of the operator with the service companies in exploring

newways of delivering today’s high‑volume hydraulic fracturing

programmes that ensures reliability in operational performance.

Innovationforholistic reliability

To drive reliability into the frack programme is to understand the

erosion effects on service equipment used in today’s hydraulic

fracturing operations.

The primary type of erosion encountered with surface frack

equipment is erosion due to solid particle impingement. Frequently,

fluctuating pressure coupled with sand loaded frack fluid can damage

the structural integrity of a frack tree. Sand, acid, andmany other

erosive and corrosive elements of a frack job reduce the life of the

frack tree’s valve gate and seat. Lacking proper attention, the high

pressure variations and chemical makeup of fluids used during a frack

job can reduce the lifespan of elastomers and other soft goods in the

valves of the frack tree (Figure 2).

In order to fully understand operating conditions and erosive effects

on equipment used in hydraulic fracturing, specifically frack trees and

manifolds, Cameron has conducted extensive erosion studies. From

these efforts, Cameron has developed engineering standards to address

erosion effects andmaintenance procedures to ensure reliability of the

frack equipment. These procedures, known as FracServ™ valve integrity

protection plan, establish a sequence of activities and inspections

designed to ensure that any degradation of frack equipment is identified

and corrected before the equipment is reassigned to another frack job.

An example of this diligence helped one Bakken operator achievemore

than 99%uptime in fracturing operations.

Another example of increased frack tree uptime is the experience of

one operator starting up development in the Fayetteville Shale. Faced

with the daunting challenge of entry into a new type of exploration

combinedwith concerns about finding quality equipment and

personnel to reach the company’s ultimate goals through adherence

to strict operating standards, the operator needed to keep fracturing

operations continuouswithout unexpected shutdowns for frack tree

repairs. Use of special valves andmethodology significantly heightened

confidence in frack tree integrity. Time lost to have a newvalve brought

to thewellsite, set a plug, and replace the faulty valve is about the

time it takes to complete a frack stage. For this operator, savings from

not having to replace a faulty valve on the frack treewas valued at

approximately US$1.5million.

In the Eagle Ford, an operator achieved performance gains through

the use of comprehensivemaintenance procedures. The operator

previously had been experiencing three to four failures per week that

had cost on average about US$2.7million permonth. Since instituting

specially designed frack trees and frackmanifolds and a comprehensive

maintenance programme, this operator achieved a valve integrity

success rate of 100%on 189 frack stacks and 72 zippermanifolds.

The onus of success in exploitation and production in today’s

unconventionals is on the reliability of necessary technology to keep

the industry moving forward. Therefore, as the gap in the ‘other 20%’

is closed, both operators and service companies will be able to thrive

in a low oil price environment.

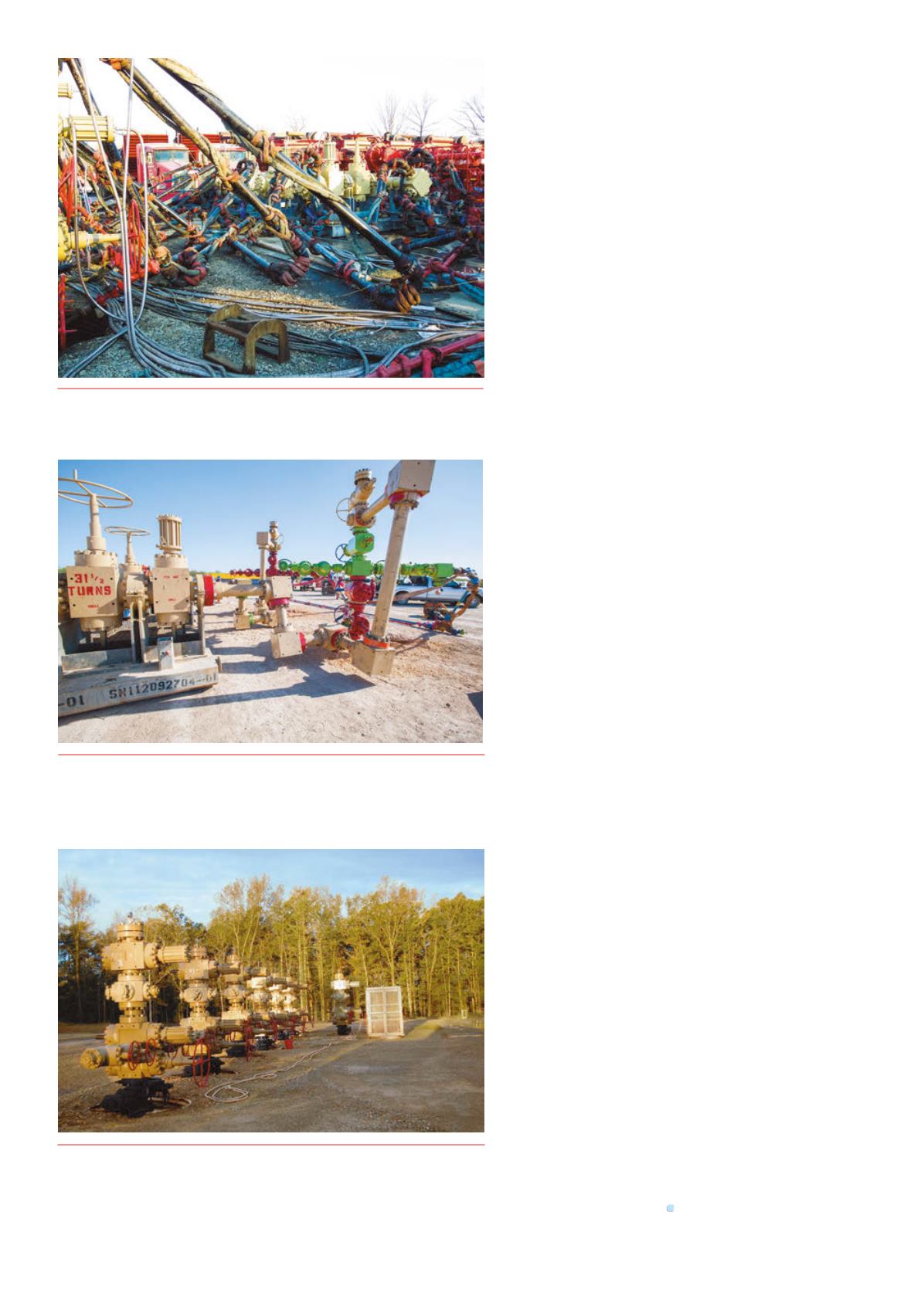

Figure 5.

One of the standard responses to these conditions has been to put

more fluid throughmore lines. But, that only adds to analready tangledmaze of

lines on thewell pad.

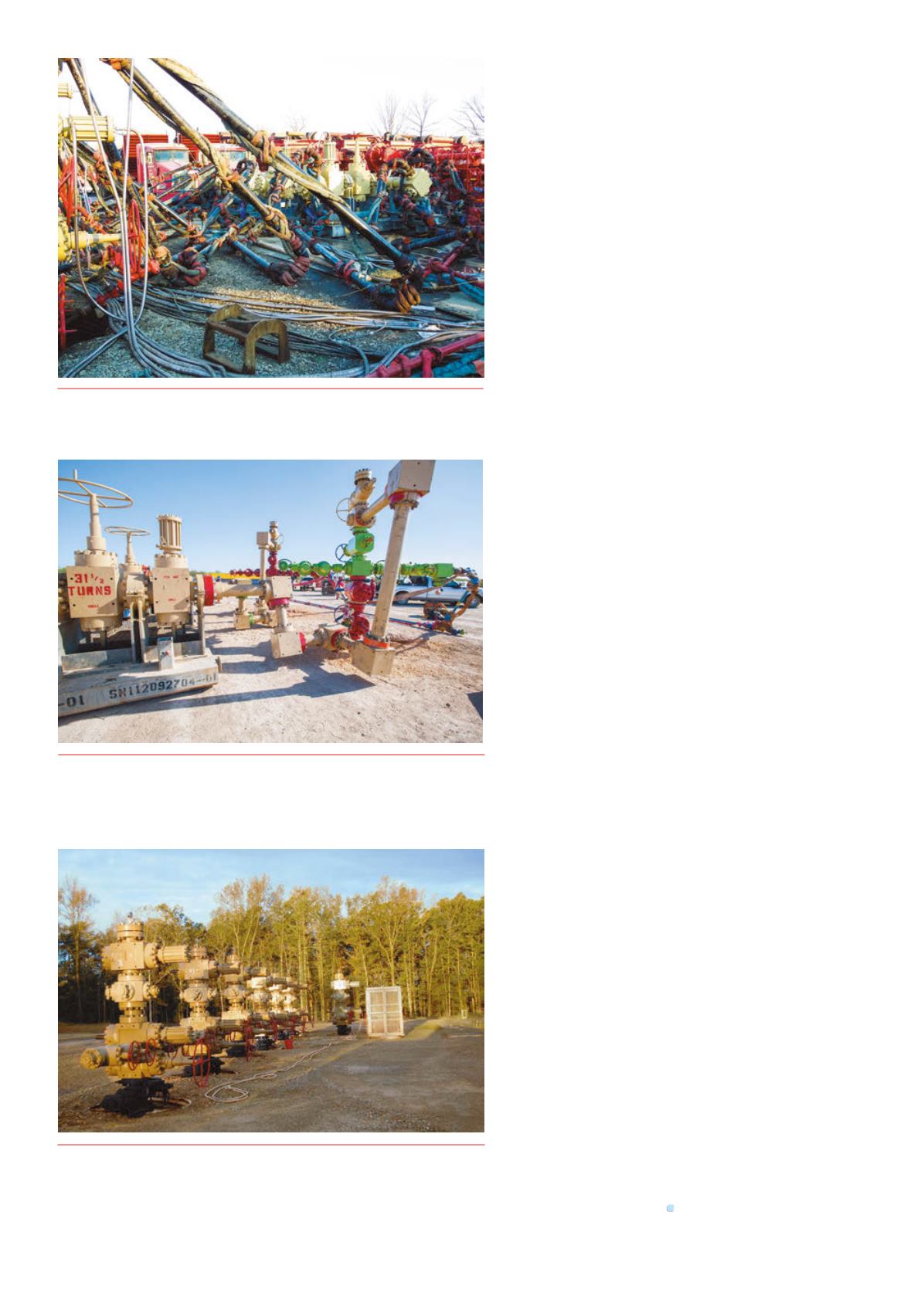

Figure 7.

FracServ™valve integrity protectionplan establishes a sequence

of activities and inspections designed to ensure that any degradation of frack

equipment is identifiedand correctedbefore the equipment is reassigned to

another frack job.

Figure 6.

One answer is Cameron’sMonoline™Frac FluidDelivery System. This

systemreplaces the need to rig-up four separate flow lines to the frack treewitha

single line featuringa large inner diameter bore to accommodate the large frack

fluid volumes required in today’s hydraulic fracturingprogrammes.