66 |

Oilfield Technology

June

2015

flooding operations operate with an oil cut of less than 20%, because

the water injected is unable to displace the crude oil trapped in

the tight carbonate rocks. Furthermore, the huge volumes of water

produced need to be treated and recycled; the higher the water cut,

the higher the operating costs. Adding surfactant formulations to

the injected water has the potential to improve the water flooding

process significantly by favourably affecting the oil cut, and the

overall oil recovery from the reservoirs.

School of rock

Carbonate reservoirs are a challenging porous rock system with pore

networks spanning a wide gamut of length scales: from the tight low

permeability matrix with length scales less than a micron, to vugs, or

connected porous networks on millimetre length scales created over

decades of water flooding, to high permeability fracture networks,

which can be a millimetre wide with length span of a few hundred

meters. The high permeability zones are easy to flow through and

are well swept by water, allowing ‘easy’ oil residing in these zones

to be recovered early on during the water flooding process. The

‘difficult’ oil trapped in tight pores is inaccessible to the water flow

path and is left behind. Furthermore, since the carbonate rocks

have a preferential affinity towards oil, water imbibition into the

tight carbonate matrix becomes very challenging. Thus, oil recovery

factors by water flooding in carbonate formations have remained low

(typically less than 30%) primarily due to:

Ì

Significant permeability contrasts leading to poor sweep

efficiency.

Ì

Significant amounts of oil trapped in tight low permeability

pores.

Ì

Low imbibition of water in tight pores.

Ì

Heterogeneous reservoir rock properties.

To improve the oil recovery factor, specially tailored chemical

formulations can be added during the water flooding process to allow

water to sweep the tight pores, effectively recovering the ‘difficult’ oil

left behind.

Enhancedwater flooding: thenew

frontier

Since carbonate reservoirs have low oil

recovery due to their preferential affinity to

oil (oil‑wet rock surface) and the trapping of

oil in tight pores, a viable method to release

the trapped oil is through the addition of

surfactants that enhance imbibition of water

in tight pores by capillary action. Capillary

action is the primary mechanism behind many

natural processes, like the rise of water in tall

trees through long slender pathways. The

phenomena of enhancing water imbibition into

tight pores and displacing oil trapped in the

pores by capillary action depends primarily on

the affinity of the rock surface (wettability) to

the imbibing medium (water), the interfacial

tension (IFT) between the imbibing fluid

(water) and the displaced fluid (oil), and the

pore diameter. The preferential oil wetness of

the carbonates and the interfacial resistance

between oil and water adversely affect the

displacement of oil through the tight pores.

A certain class of specially designed

surfactant formulations can significantly

enhance the capillary imbibition of water by

altering the affinity of carbonate rock surface

from oil (oil‑wet) to water (water‑wet). Through

application of such formulations, oil attached

to the rock is released and the imbibition of

water into tight matrix is enhanced. This results

in the further release of additional oil, while

allowing more water to be imbibed into the

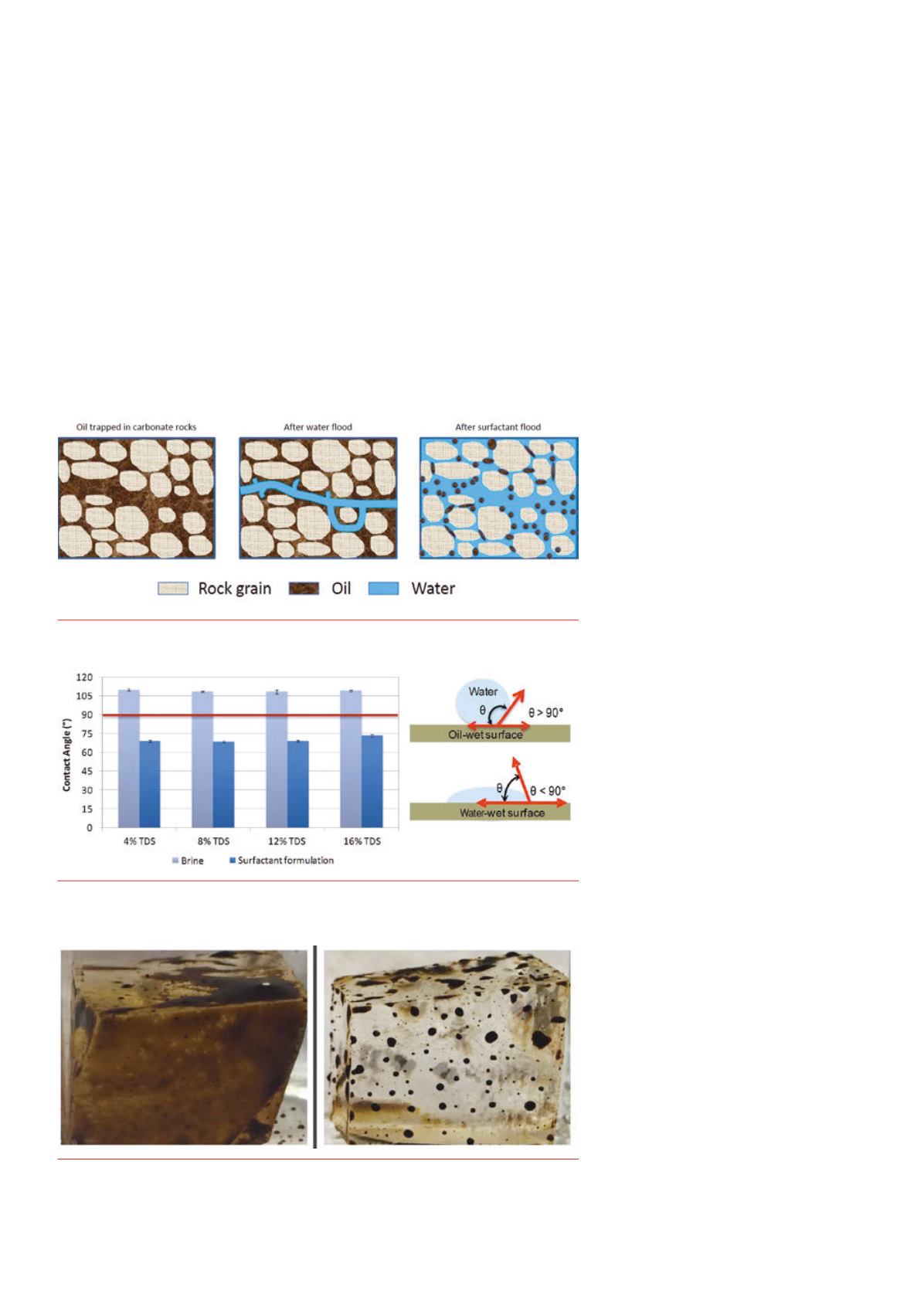

rock matrix. An illustration of this concept is

shown in Figure 1. Furthermore, if more water

can be injected while keeping the injection flow

pressure constant, more fluid can be produced

without any additional energy input. The

application of such surfactant formulations

must be economically viable. Therefore, the

surfactant formulation must be an effective

wettability altering agent at low dosages.

The phenomena of wettability alteration

of rock surfaces can also be achieved by

Figure 1.

An illustration of enhanced imbibition of water in oil‑wet carbonate rockmatrix using

surfactant formulation.

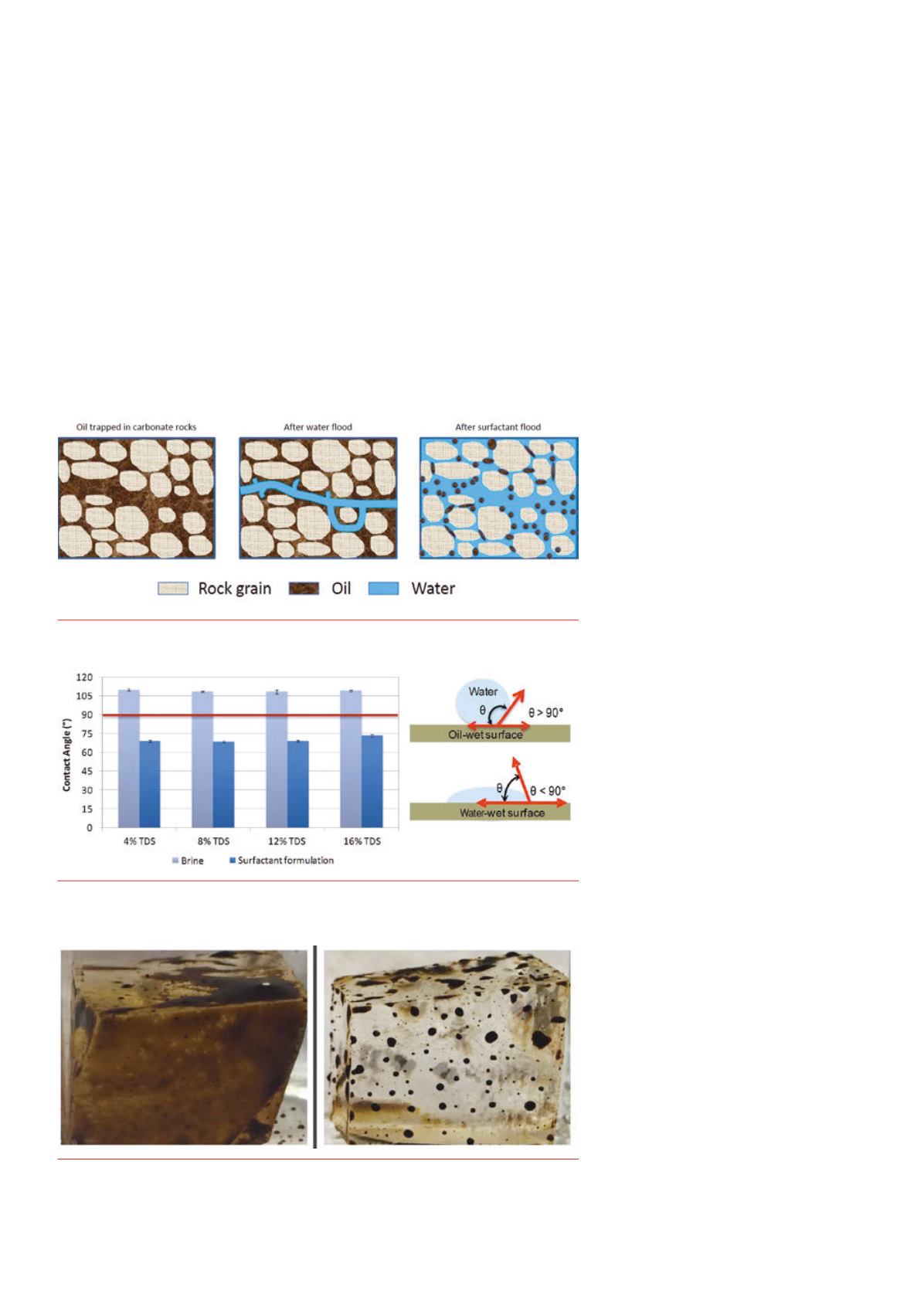

Figure 2.

Contact angle results for brine ona hydrophobic surface before andafter addition of

surfactant formulation (left); and schematic illustration of the change in contact angle ona surface

after wettability alteration fromoil‑wet towater‑wet state (right).

Figure 3.

Visuals of oil–wet calciteplates exposed tobrine (left), and surfactant formulation inbrine

(right). The calcite plate on the right shows the oil has been etched out and the oil‑wet surface has

beenmodified to becomemorewater‑wet.