June

2015

Oilfield Technology

|

53

bits, a proprietary body construction was developed. This new

body type, called ‘composite‑bodied’, includes a high strength

steel structure and a thick tungsten carbide matrix shell. Because

the primary structure of the bit is steel, composite‑bodied bits

enjoy all the performance benefits of steel‑bodied bits. Further,

because the tungsten carbide shell contains a higher percentage of

carbide than a conventional matrix‑bodied bit, the wear resistance

of the new body construction is higher than that of matrix bits. As

seen in Figure 3, even in bits of identical cutting structure design,

the composite body far outlasts matrix bodies in comparable

applications. The pictures shown in Figure 3 are of SHEAR BITS’

Oilsands Series PDC bit designs that drilled lateral intervals in

Canadian oilsands applications. This application is well known

to be one of the most challenging in the world with regard to bit

body wear, as is exemplified by the extreme matrix loss on the

matrix‑bodied bit runs.

2

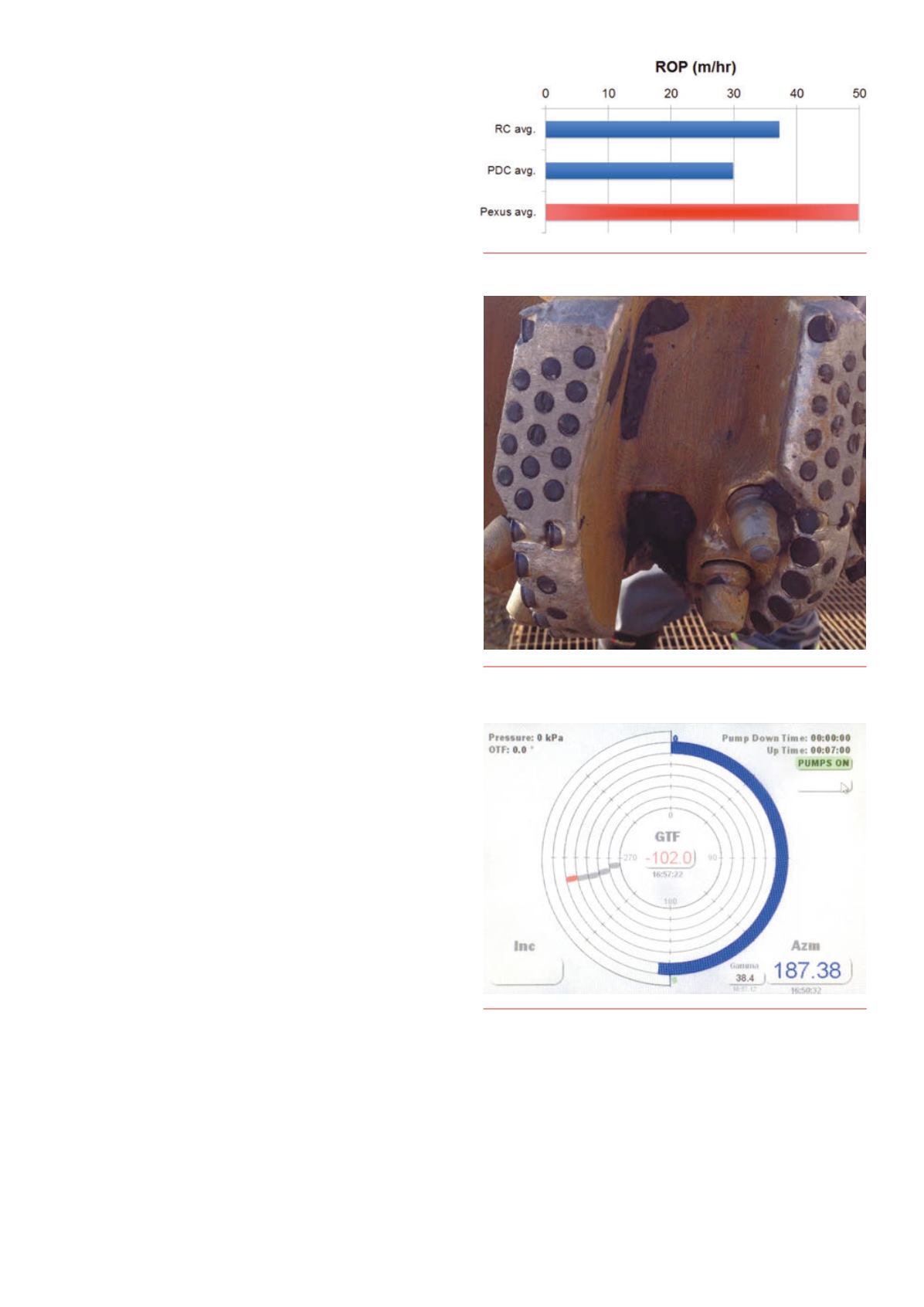

Over the last 1 ½ years, Pexus hybrid bits have proven to be

successful in drilling large diameter vertical surface intervals

throughout Western Canada.

1

However, there are many more

applications where this technology has already proven to

be of significant benefit to drilling programmes. The hybrid

gouging/shearing cutting structure has demonstrated smoother

drilling behaviour and greater resistance to impact damage than

conventional PDC bits, and also higher ROP than rollercone bits.

Therefore, in many situations where directional drillers struggle

to control PDC bits, or resort to running rollercone bits in order

to achieve the directional targets, Pexus technology can deliver

improved ROP and durability. Additionally, in applications where

the formation is either heavily interbedded or contains significant

percentages of conglomerates, chert or pyrite, Pexus technology can

enhance performance over conventional bit types.

Intermediate and production holes are commonly drilled

with either PDC or rollercone bits, both of which have their own

unique set of disadvantages. Drilling with rollercones often means

compromising on ROP and commonly requires multiple trips to

complete an interval, whereas PDC bits often lack steerability and

suffer from durability issues in highly transitional and interbedded

formations. Applying Pexus technology in these situations has

produced improved performance in hole sizes from 6 ¼ in. up to

12 ¼ in. diameter. In larger hole sizes, such as 10 ⅝ in. to 12 ¼ in.

diameter, directional programmes with relatively high build rates

can be very challenging with PDC bits due to the torque response

that comes along with shearing cutting structures. The total

torque output of any drill bit is relative to the diameter of the

bit as larger bits require more torque to drill. The fluctuations in

torque response from a PDC bit also increase in proportion to its

diameter. Therefore, larger diameter PDC bits create both more

overall torque and larger swings in torque as they drill. As a result

of this situation, as the diameter of the bit increases, the likelihood

to perform directional work with a PDC versus a rollercone bit

decreases. In other words, in larger hole sizes, it is still more

common to drill challenging directional intervals with rollercone

bits instead of PDC bits.

In order to tackle smaller diameter build and lateral intervals

more effectively, SHEAR BITS has developed a new approach to

the Pexus gouging insert layout and blade geometry to incorporate

all of the benefits of the technology in bit sizes as small as 6 ⅛ in.

(156 mm). Unlike the ‘full gouging’ layout, where there are gouging

inserts in front of every blade of PDC cutters, used in larger hole

sizes that has proven to be highly effective in applications that

contain large gravel or conglomerates, the design strategy for

smaller hole sizes only incorporates gouging inserts in selective

regions of the bit. Figure 5 shows an example of one Pexus hybrid

design for lateral production intervals. The 6 ¼ in. (159 mm)

SHP613D has gouging inserts mounted only in front of the three

secondary blades of the bit, and includes six nozzles to effectively

dedicate hydraulic energy to every blade of PDC cutters. This layout

improves cooling and cleaning around all of the PDC cutters to

increase cutter life and ROP, while still providing the durability and

behavioural benefits of the gouging cutting mechanism.

Figure 6.

ROP comparison in 12¼ in. oilsands build interval.

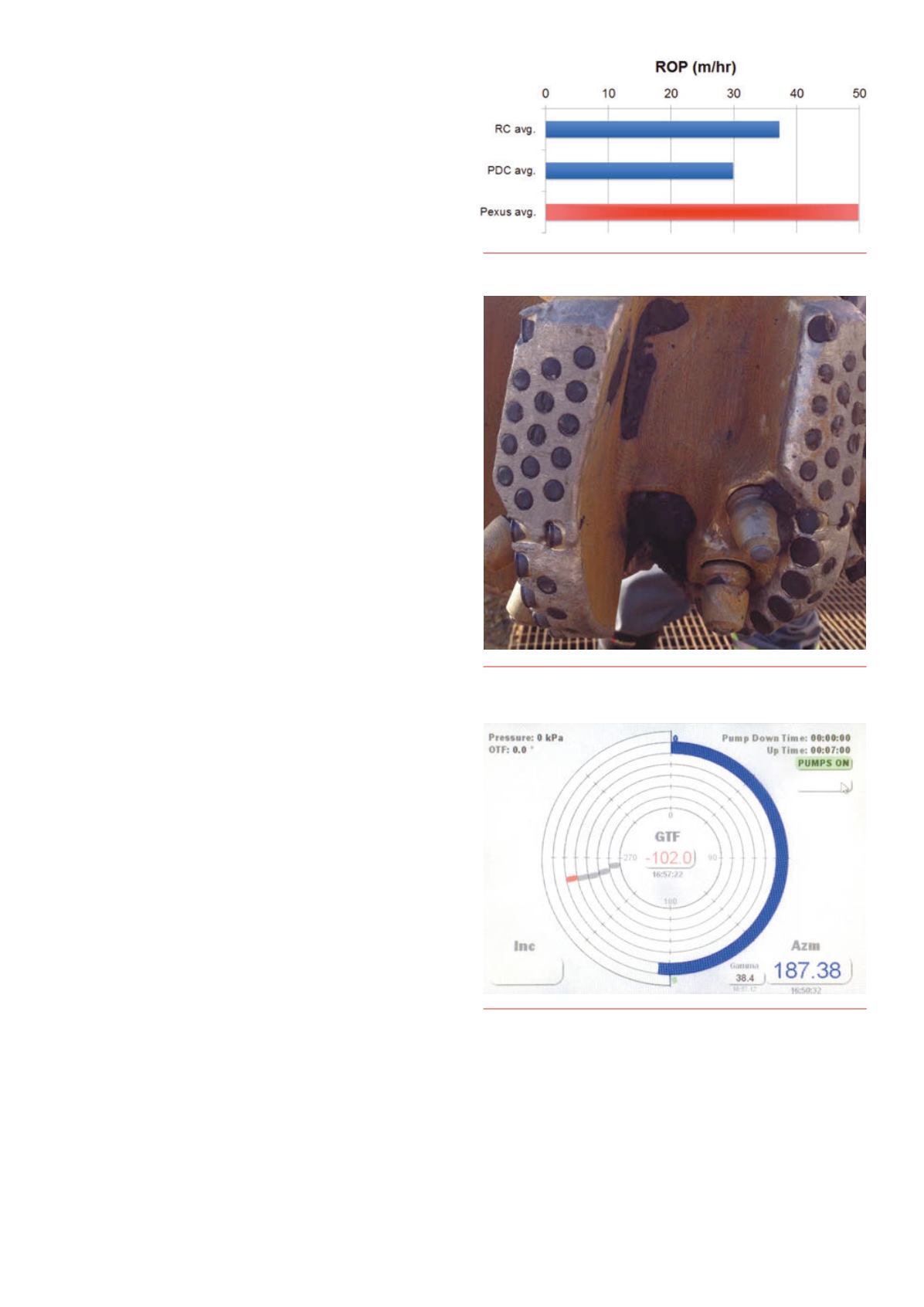

Figure 7.

Dull condition of a 12¼ in. Pexus hybridbit after completinga

challenging S curve interval.

Figure 8.

Photo of toolface plot takenduringa slide in the 6¼ in. SHP613D

run.