service to potential new customers – the Summit project

involves installing more than 2 million ft (609 600 m) of

6 in. (15.2 cm) HDPE natural gas pipe through some of the

densest rock found anywhere in the US. When complete,

this extensive pipeline network will provide natural gas

to the towns of Gravois Mills, Laurie, Sunrise Beach,

Camdenton, Osage Beach and Lake Ozark, Missouri.

More than 30% of the pipeline – approximately

600 000 ft (182 880 m) – is being installed by horizontal

directional drilling (HDD) technology. The largest and

most costly components of the Summit project – three

trenchless bores beneath the lake at sites alongside the

three major bridges in the area: the Community Bridge,

Hurricane Deck and Niangua – were also the most visible

and challenging. Lone Star Directional Drilling, based in

Clarksville, Texas, was selected by general contractor

J.F. Construction Services, based in DeWitt, Missouri, to

complete the bores. John Dagenhart, founding partner of

Lone Star Directional Drilling and a 20-plus year veteran

of HDD, explains the rationale for selecting the Vermeer

D1000x900 Navigator® horizontal directional drill for the

challenging lake-crossing bores.

“We’re using the D1000x900 drill for many reasons,”

Dagenhart says. “For a maxi drill, the D1000x900 drill is

a relatively easy system to operate…and it’s powerful.

The drill is also very durable and reliable, which is

important given the complexity and the length of the

three lake crossings. We knew the D1000x900 drill had

the capabilities to effectively power through the rock. But

because of the intricate complexity of the lengthy bores,

accuracy and durability are also critical.”

High visibility; strict tolerances;

environmental sensitivities

Dagenhart recalls the first visit he made to the lake with

Jim Frock, founder of J.F. Construction Services, to survey

the new Summit project installation route.

Among the many objectives of the trip was

to identify launch sites with enough area to

accommodate the drill and various support

equipment necessary for completing the

three lake crossings as specified in the drill

plan.

“Finding launch sites with enough flat

area in close proximity to where we’d be

drilling was a challenge,” Dagenhart says.

“There are few areas of flat space desired

for launch sites because the steep terrain

is prevalent right up to the lake’s edge.

All three bores were also situated near or

alongside bridges, where the depth of the

water averages from 90 ft (27.4 m) to more

than 100 ft (30.5 m). Since we were required

to maintain a 40 ft (12.2 m) clearance, the

bores needed to reach a depth of 150 ft

(45.7 m) very quickly; a challenging feat given

the proximity of the launch sites to the

lake’s edge.”

The first bore, completed alongside the Niangua

Bridge, consisted of a continuous 3500 ft (1066.8 m)

shot that took just less than a month to complete.

The second was a 3600 ft (1097.3 m) shot located near

the Community Bridge. Just completed, the third and

final lake crossing was a 6000 ft (1828.8 m) bore near

Hurricane Deck where, coincidentally, a new bridge was

also being built.

“Construction of the new bridge, along with concerns

levied by the bridge construction contractor involving the

demolition of the old bridge, prompted an alteration to the

tolerance,” Dagenhart says. “The specified tolerance on that

bore was increased to 100 ft (30.5 m). As a result, the bore

near the Hurricane Deck Bridge required reaching a depth

of 278 ft (84.7 m) quickly.

A 9 7/8 in. (25.1 cm) chisel bit with tungsten carbide

inserts was chosen for all three bores. “We’ve found that

once we encounter rock in excess of 6000 psi (413.7 bar),

depending on the pipe we’re installing, bits with tungsten

carbide inserts will last longer,” Dagenhart says. “This was

important on a bore of this length, beneath the lake, that

we not have to pull back and change a worn bit before

completing the shot. Experience told us this was the type

of bit we needed to use.”

In addition to the limited space for establishing a launch

site and strict tolerances required in the drill plan, the hard

rock – much of which is fractured in gravel, cobble and

some limestone – presented additional challenges for the

Lone Star drill team. Given the tough conditions, Dagenhart

has been pleased with the average daily production rates

by the D1000x900 drill of approximately 300 ft (91.4 m)

per day. “If we can average 10 pipe joints a day, we’re very

happy,” he says.

Back reams were not necessary on the first bore,

although, on the Community Bridge crossing, where the

drill plan specified 8 in. dia. (20.3 cm) steel pipe versus the

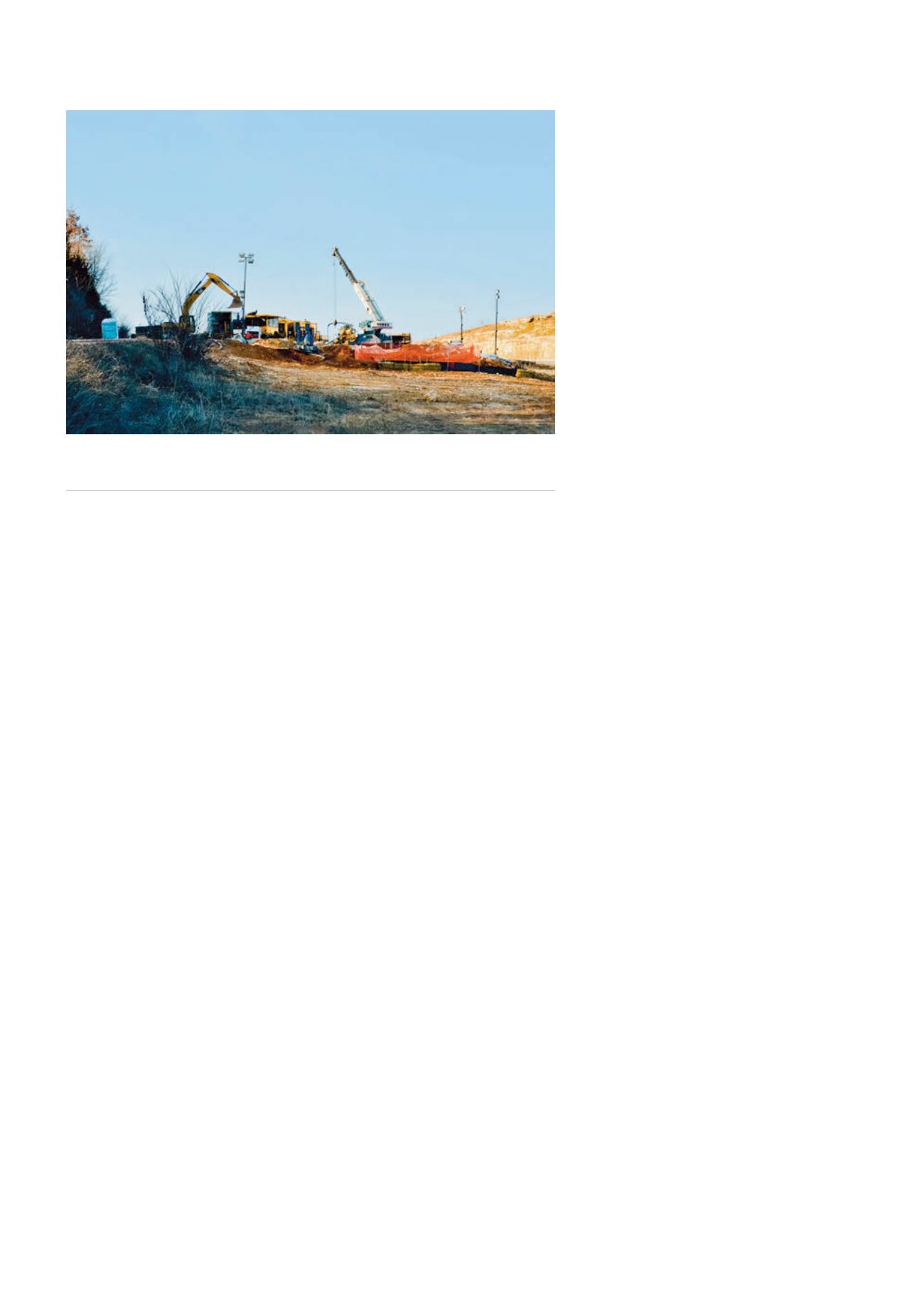

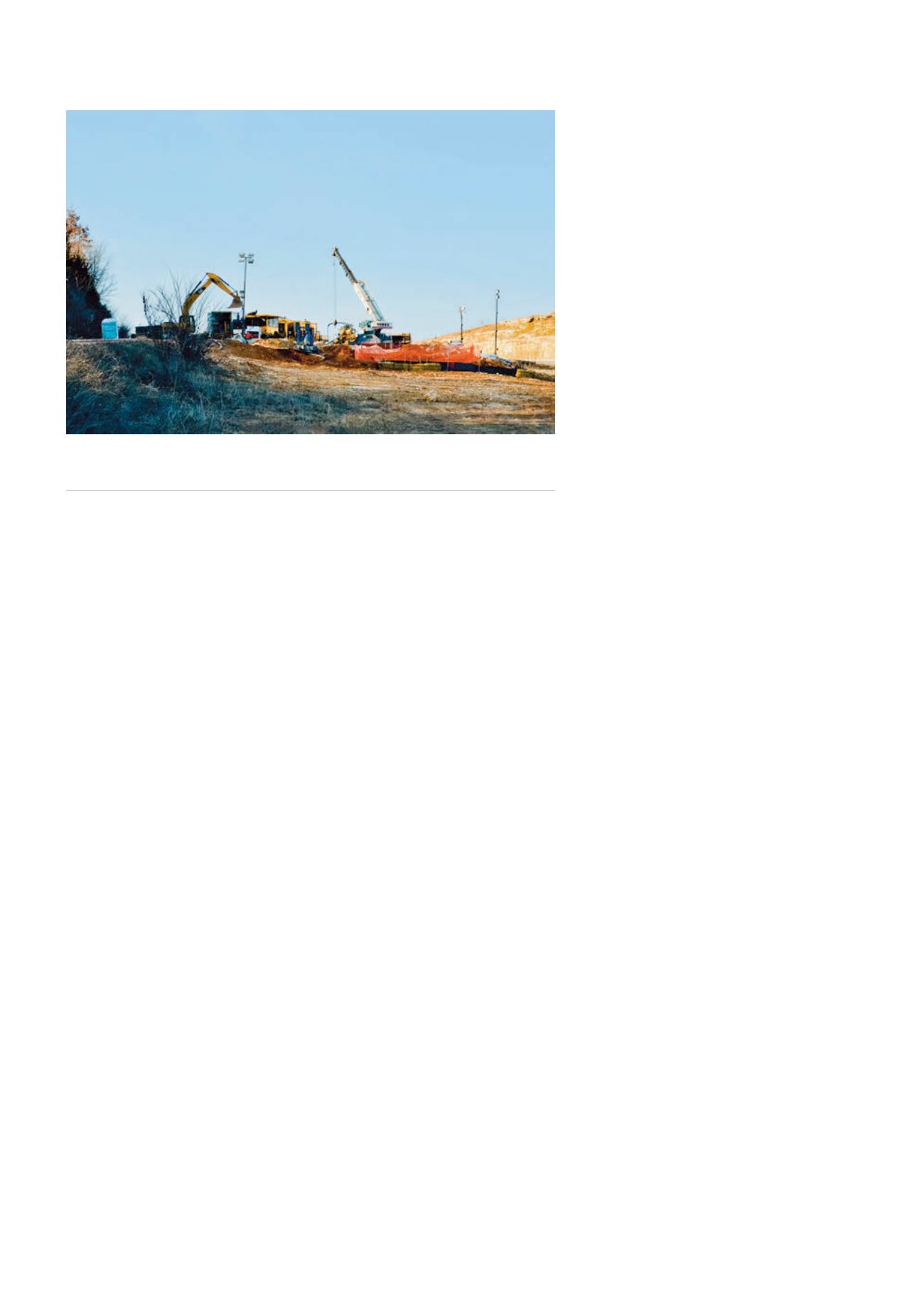

Figure 2.

Lone Star Directional Drilling works on three trenchless bores on the

Summit project near the Lake of the Ozarks. The three bores are located beneath

the lake at sites alongside three major bridges in the area.

118

World Pipelines

/

JUNE 2015