equipment is set up on the entry side – in this case, near

Rio Grande City, Texas. The 750 t thruster and Direct Pipe

machine were welded to the product pipe and launched

from inside a shallow sheet-piled pit on the Texas side.

The operator’s control container was placed beside the

launch pit. The machine and pipe was precisely steered

along the alignment to a small, simple retrieval pit on the

Mexican side of the crossing.

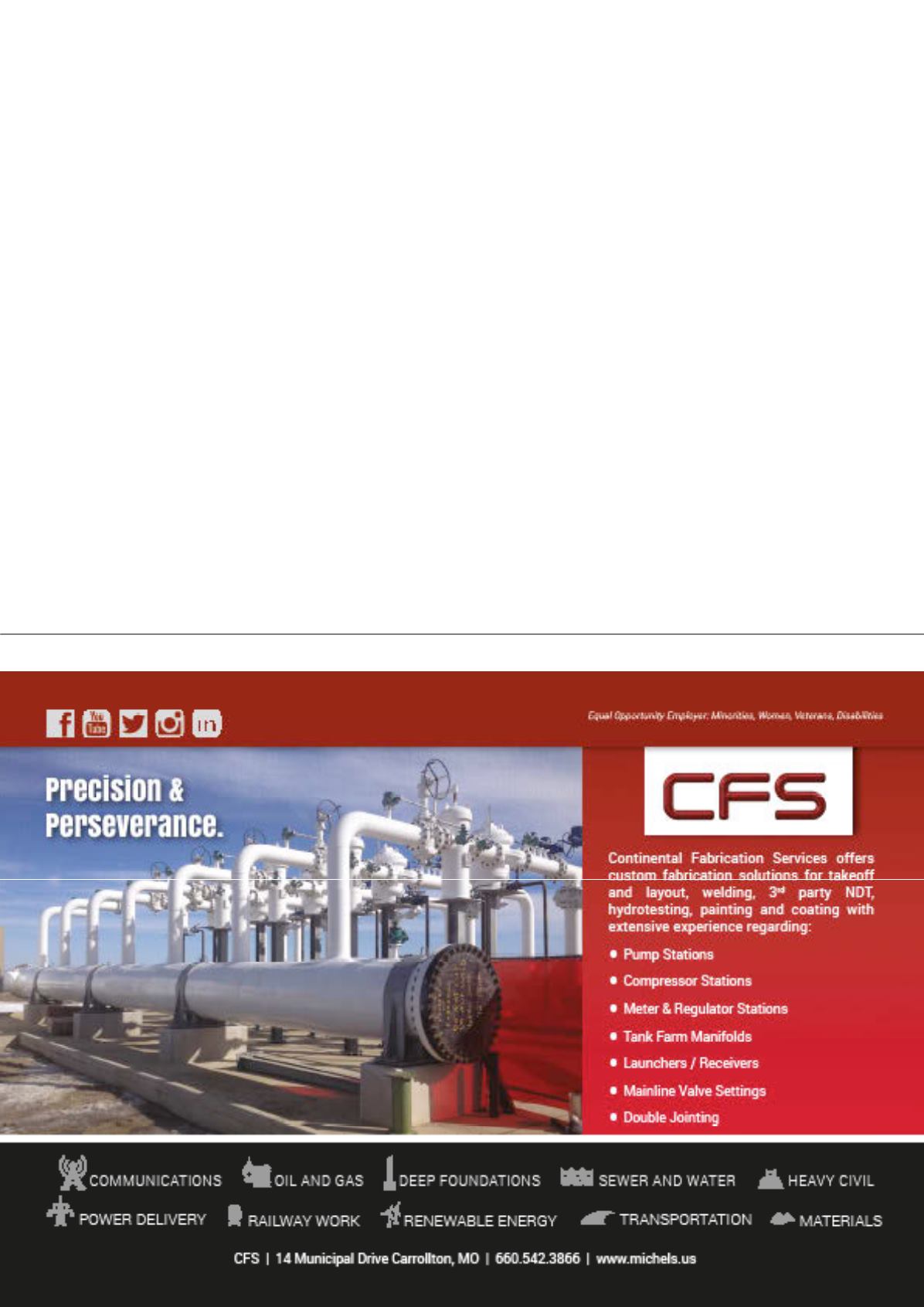

Michels is among the world’s most experienced

contractors using Direct Pipe and has succeeded at many

other challenging projects. Direct Pipe is a single-pass

installation that combines microtunnelling and a thrusting

system to directly install steel product pipes.

An operator on the surface monitors and corrects alignment

changes and controls the tunnelling head and thrusting unit

simultaneously. A gyro-compass is used for horizontal orientation

and a hydraulic water levelling system is used for vertical

orientation. The two combine to allow for an accurate curved

drill the same as an HDD installation in relatively shallow depths.

For the Rio Grande crossing, depth of about 40 ft was realised.

Keeping to schedule

As always, Michels’ comprehensive planning and construction

management procedures played key roles in the ultimate

success of this project. As such, long before crews arrived at

the Rio Grande, extensive preparations were put into place.

Michels is proud of the size, diversity and condition of

its equipment fleet. The company’s talented support teams

maintain the equipment and make sure the right pieces are

ready to be mobilised to the project sites. For this project,

a thruster, Direct Pipe machine, mud cleaning system and

support equipment was required for Direct Pipe and pipeline

management.

Michels is aware that any down time not only impacts

the overall project, but the customer and affected property

owners as well. By keeping its equipment in top condition and

by training its teams to quickly diagnose and respond to any

unanticipated mechanical issues, Michels strives to keep the

project on the committed schedule.

This project presented several unusual elements that

were also addressed before mobilisation. As always on

Michels’ projects, the safety of its crews, customers and the

communities in which it works is of paramount importance.

The company’s project management and HSE teams have

vigorous standards for safe working conditions.

A local contractor was hired from Mexico to assist

with removal of the machine from the retrieval pit and to

transport it back to the US. Throughout the duration of the

project, and with the co-operation of its project partners,