type of equipment, without any heat-affected zones and with

optimal, consistent high quality.

Special cases concerning processes using

high density energy sources

High density energy source processes concern laser and electron

beam welding. Both processes use a beam (a laser or electron

bombardment) accurately focused to make the energy that is

aimed at the part to be welded melt the metal. Using these

techniques, welding can be performed over depths of several

hundred millimetres in a single pass and with a bead that is rarely

more than 5 mm wide.

Assemblies welded in this way do not require bevels but

extremely accurate facing on part ends. For example, preparation

for laser welding will be acceptable if the alignment fault is less

than 1/10

th

of a millimetre. Moreover, parts must be totally free

of any contamination for using these technologies successfully,

especially electron beam welding. As electron beam welding

operations are carried out under vacuum conditions, no water

or hydrocarbon residues must be allowed to enter the chamber

as their presence is liable to make creating a vacuum a more

delicate task.

Using these ultra hi-tech methods requires the presence of

suitable machining equipment capable of perfectly preparing the

ends to be welded.

Welding is always a delicate operation. A large number of

parameters have to be known and mastered for obtaining the

best possible results. Otherwise, they are all as many defect

causing factors liable to occur during or after completing the

welding bead and which may deteriorate the quality of the total

assembly.

Despite upgrading techniques and increased knowledge on

the subject, industrialists are regularly confronted by problems

involving non-conform welded joints. The consequences of a

poor weld can be disastrous for the success of a project, in terms

of both schedules and budgets. Eliminating a welding bead and

re-building it may take several hours or even several days in the

case of major assemblies.

Correctly preparing the edges to be welded will never

prevent 100% of all the reasons for defects from occurring, but

it will increase the final quality of the welded assembly in every

single case.

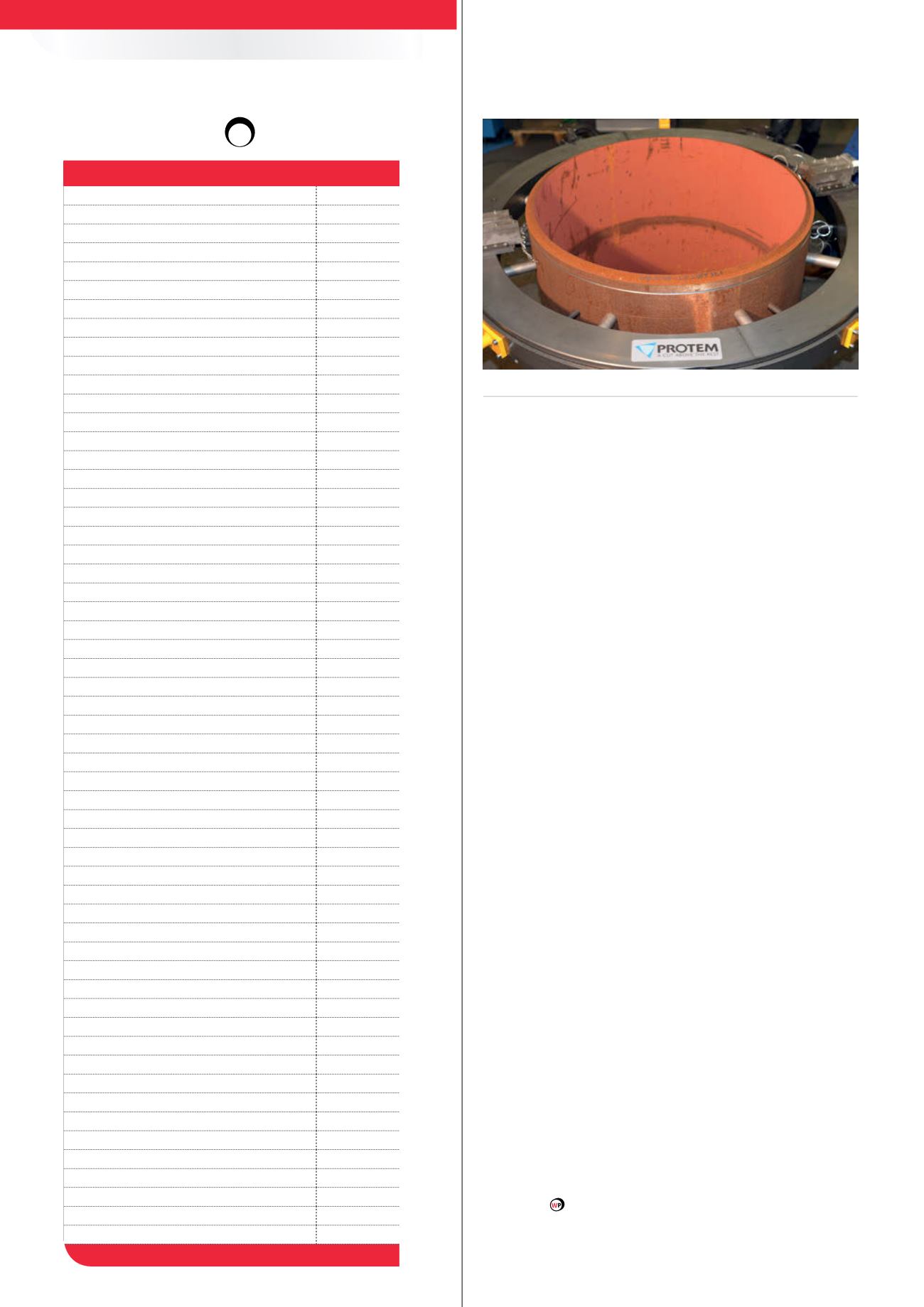

Figure 6.

Protem splitframe TTNG.

Advertisers’

Direct

o

ry

Advertiser

Page

ABC

58

ADIPEC

54

Aegion

51

American Augers

45

APS Dubai

76

Baker Hughes

41

Canusa-CPS

9

CFS (Continental Fabrication Services)

115

CRC-Evans

OFC, 21, 106

DENSO GmbH

39

Denso North America, Inc.

97

Enduro

OBC

Erciyas

47

Farwest Corrosion Control Company

111

FlexSteel Pipeline Technologies, Inc.

91

Girard Industries

76

Gulf Interstate Engineering

27

Hoelscher Dewatering

80

Holdtight Solutions, Inc.

61

IPLOCA

100

Laurini

37

Maats Pipeline Equipment

6

Magnatech International

IBC

Mears Group, Inc.

123

Midwestern

4

NACE

79

NDT Global

17

Neptune Research, Inc.

23

Pigs Unlimited International, Inc.

33

Pipeline Inspection Company Ltd

65

Pipeline Machinery International

2

Polyguard Products

29

Polysoude

70

Prosoft Technology

57

Protem

86

PWT

89

Quest Integrity

109

RAE Energy

73

Rosen

IFC

Schoenbeck GmbH & Co. KG

116

Shaw Pipeline Services

11

STATS Group

53

Sulzer

85

T.D. Williamson

13

The Pipeline + Energy Expo

TM

100

TPS 15

48

Tracto-Technik GmbH & Co. KG

99

Tri-Tool

66

Tulsa Rig Iron

120

Universal Pegasus International

83

Vacuworx

69

Vermeer

63

Volvo

105

Wasco

103

World Pipelines

75, 119, 120

Worldwide Machinery

93