resulting weld deposits exhibit excellent tie-in and a flat

bead profile (Figure 2). Additionally, spatter and overspray

levels are the lowest in the industry, with high deposition

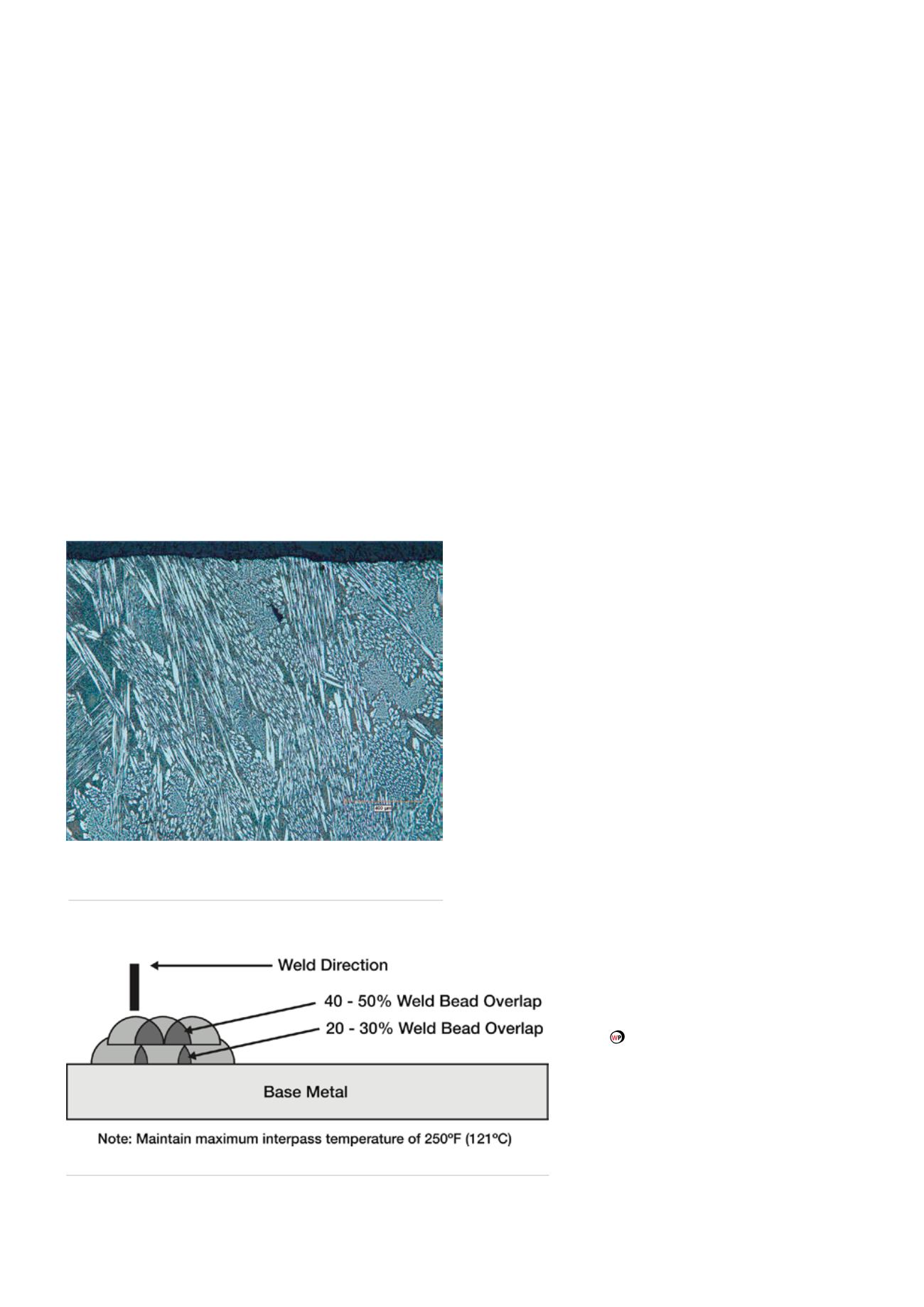

efficiency. The resultant weld deposits can be characterised

by a high concentration of uniformly-distributed primary

chromium carbides throughout (Figures 3 and 4).

Procedures for the reapplication of chromium

carbide cladding on a worn elbow

The following section assumes a worn elbow has been taken

out of service following inspection.

)

)

Prior to repairing the existing cladding, the elbow

should be preheated in a large oven to 600°F (316°C)

in an attempt to burn off as much of the hydrocarbon

contamination on the surface and within the cross

check cracks of the original chrome carbide overlay as

possible.

)

)

Next, the inside diameter of the pipe surface should be

cleaned and inspected for spalling prior to welding the

new chromium carbide overlay.

)

)

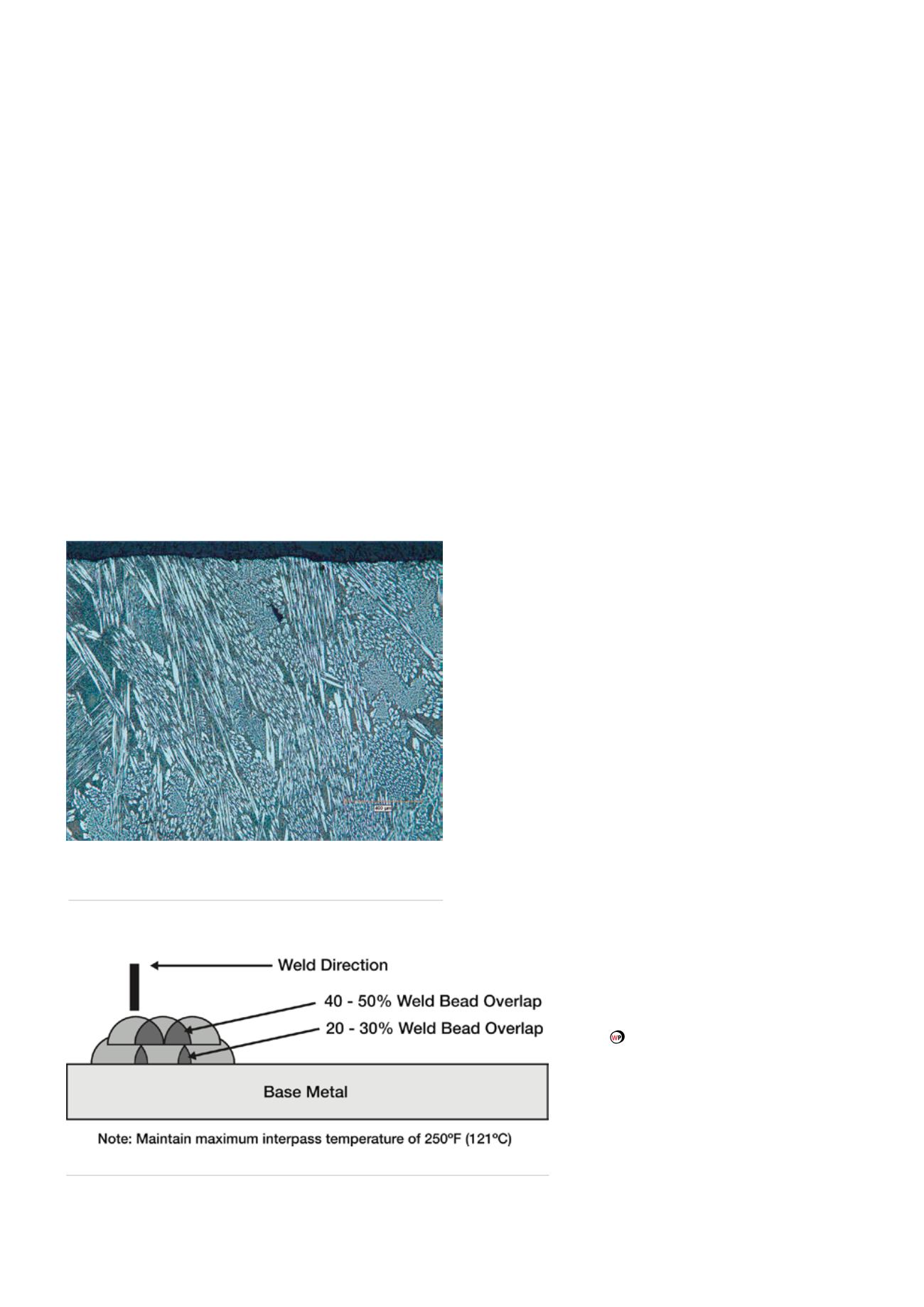

The recommended welding procedure includes the use

of stringer beads with 20 - 30% tie-in on the first layer

to establish a uniform cross check pattern (Figure 5).

This first layer is primarily used to achieve a new base

layer of chromium carbide over the top of the existing

worn overlay deposit, which may still contain a high

level of hydrocarbon contamination in the cross checks.

It is normal to see some porosity in this first layer,

although the amount can be greatly reduced by opting

to use a modified chromium carbide formulation like

Stoody PR2009 due to the high level of deoxidisers

formulated into the wire design.

)

)

A second layer of chromium carbide should then be

deposited over the first layer. If using Stoody PR2009

the degree of porosity will be substantially reduced

(Figures 1 and 2).

)

)

The weld surface of both layers should contain

cross check cracks perpendicular to the weld bead

and have hairline fractures spaced approximately

3/8 - 5/8 in. apart along a single bead. The two factors

that determine cross-check frequency and spacing

are the Interpass temperature (cooling rate) and bead

configuration. This is normally controlled by spraying

a mist of water on the outside surface of the elbow or

pipe a suitable distance from the arc on the inside of

the pipe. The cooling spray should not be directly on

the outer surface of the pipe where the welding is taking

place. If the Interpass temperature is not controlled and

becomes excessively high or the bead width too wide,

(Figure 5) the cross-check pattern will grow to greater

than 1-¼ in. apart with wide cracks running perpendicular

and longitudinal to the weld bead. Large cracks can

possibly cause catastrophic failure such as spalling.

Conclusion

With the current low price for oil placing the industry under

considerable pressure to reduce costs, one area where

savings can be made is in pipeline maintenance. In particular,

selecting the right consumable and process for cladding the

internal diameter of sections of pipeline and elbows that

have suffered abrasive wear can achieve very favourable

results. Although the optimum consumable

may not have the lowest purchase price,

the excellent deposition and weldability

characteristics in the presence of hydrocarbon

contamination, coupled with the long-term

resistance to further abrasion, can deliver a

valuable overall reduction in maintenance

costs.

NOTE: The information contained in this article

is a general overview regarding pipe and elbow ID

cladding and is for informational purposes only.

Individuals should consult with their vendor/vendor

literature for guidance in determining optimal welding

procedures for any applications.

Figure 5.

Horizontal welding – stringer bead profile.

Figure 4.

A 100X photomicrograph of the Stoody PR2009

weld deposit surface shows the concentration of uniformly

distributed chromium carbides (white) in an iron-based matrix.

124

World Pipelines

/

JUNE 2015