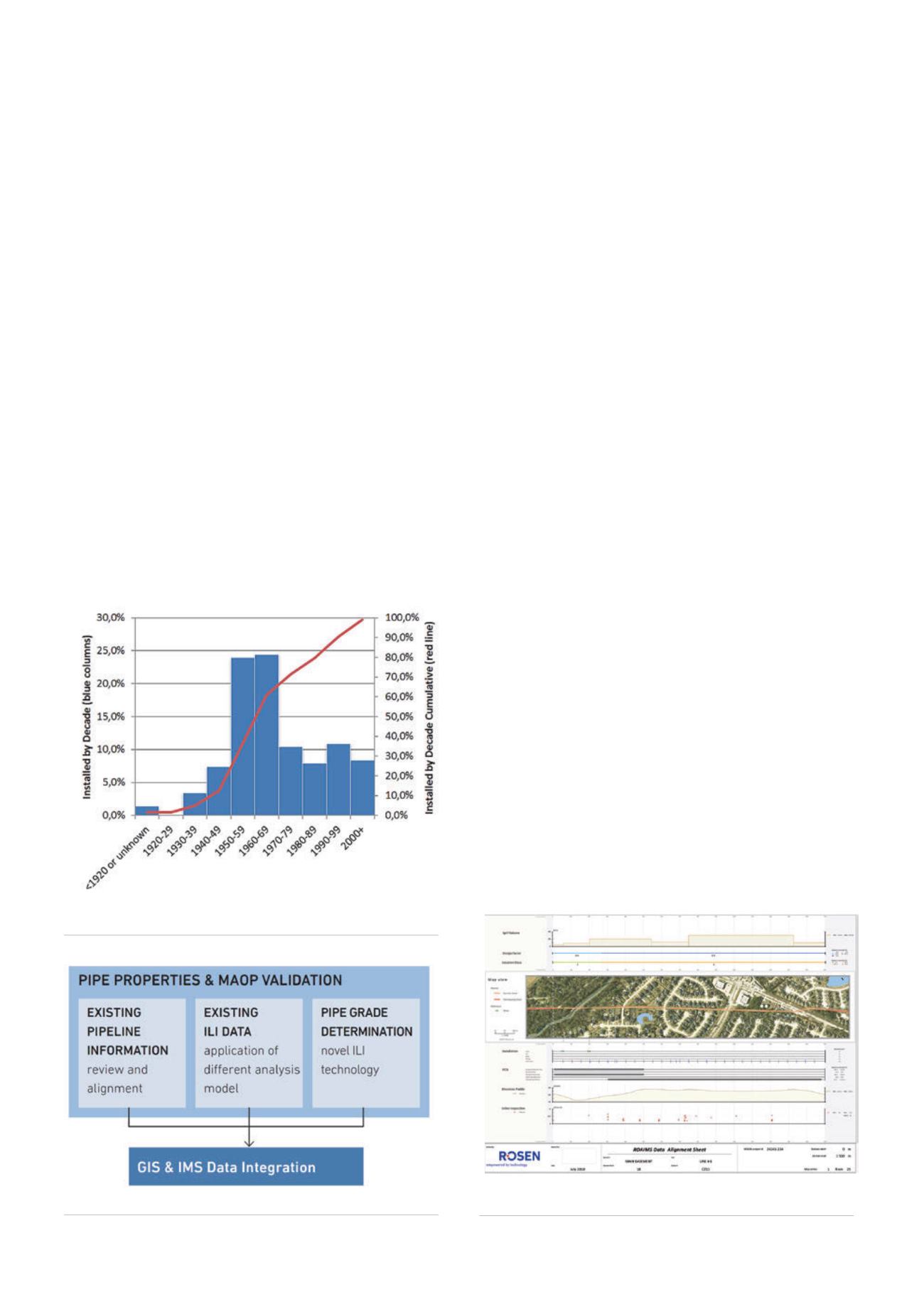

The example of natural gas transmission pipelines in the

US alone (Figure 1) reveals the challenge the pipeline industry

is facing today. According to Kiefner and Rosenfeld (2012),

approximately 66% of all natural gas transmission pipelines in the

US were installed prior to 1970.

1

This translates into 200 000 miles

(320 000 km) that are likely affected by incomplete and/or

uncertain records.

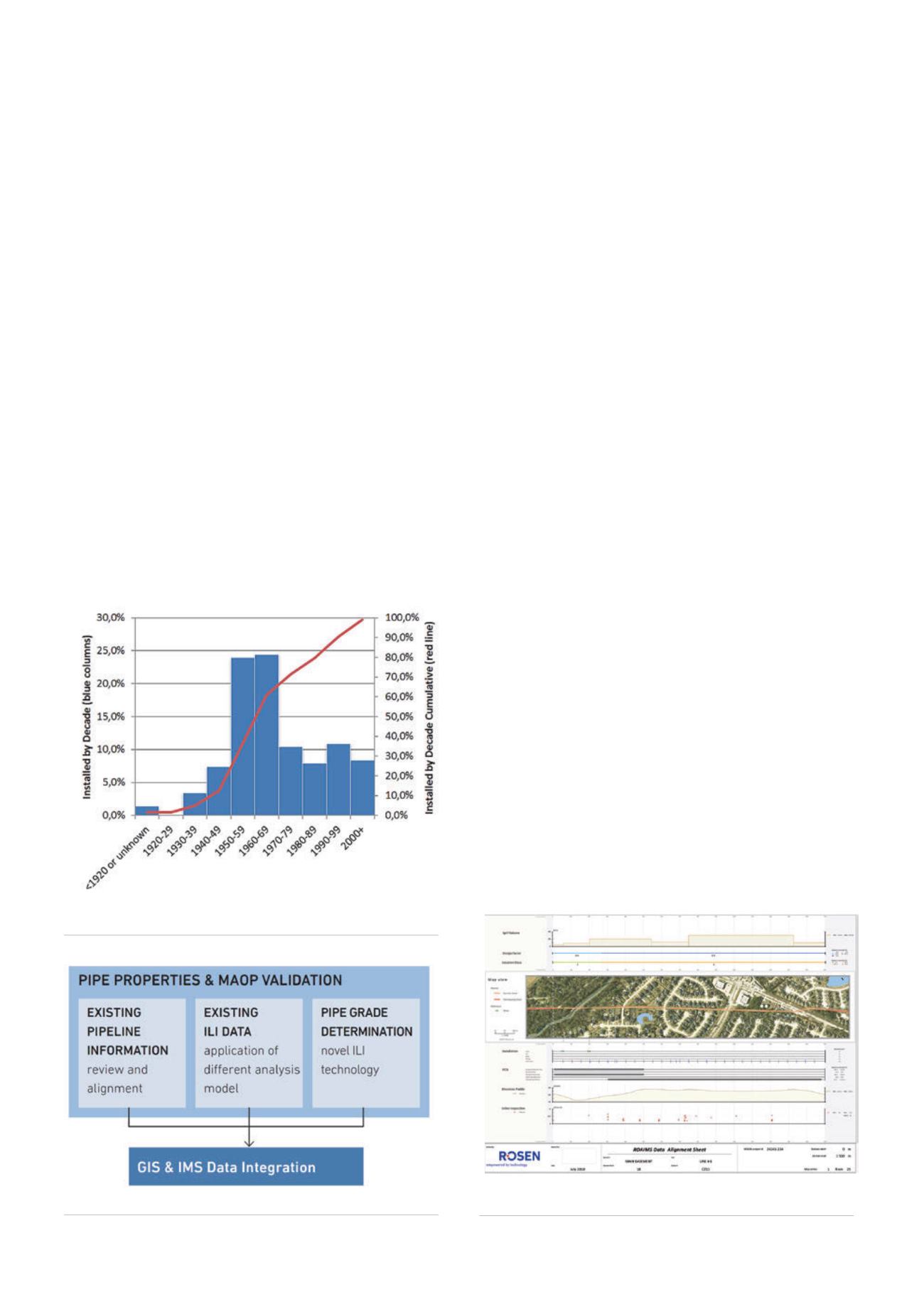

The integrated approach

With a novel integrated approach, ROSEN offers a service for

pipeline property and MAOP validation at highest confidence. The

company’s integrated approach is:

)

Verifiable – confirmed by other complementary, but separate,

documentation.

)

Traceable – originating from specific sources containing all

information for MAOP calculation.

)

Complete – finalised and evidenced by signature, date or

other appropriate marking.

ROSEN’s integrated approach comprises of three

complementary activities. The combination of these activities

addresses all aspects required for the validation of the maximum

allowable operating pressure. The gathered information is prepared

for easy integration into a geographical information system (GIS)

and to be further processed in an integrity management system

(IMS). The combination of activities is adjusted to project specific

needs. This ensures an optimised process and the highest possible

efficiency.

A comprehensive review and alignment of records

(centrelines, associated data, as-built drawings, pipe-tallies

including design calculations of piping, fittings, hydrotest pressure

records, previous and current operating conditions, MAOP, etc.) is

provided. Analogue information is digitised and incorporated into

a GIS or IMS database.

The high degree of automation of the ROSEN data analysis

routines and processes, and redesigned algorithm allow for

efficient, in-depth analyses, of existing ILI data obtained from

previous inspection runs with regards to pipeline properties,

which at the same time are used to validate and update route

information coming from a pipeline GIS.

Challenges of MAOP validation

Conventional ILI technologies are capable of delivering relevant

information for MAOP calculation, such as wall thickness and

diameter. However, as a missing element, in the past there

has been no economic means for accurately measuring yield

strength. When pipe yield strength data is missing, operators are

required, by regulation, to either base the MAOP calculation on

conservative assumptions of yield strength or remove the pipe

from service for destructive tensile testing. Aware of the existing

market need, ROSEN has developed the first ILI system capable of

continuously identifying and differentiating the pipe steel grade

and its subsequent yield strength.

ROSEN’s innovative material characterisation services RoMat

assists the operator and provides an assessment of the pipe

property yield strength of each pipeline joint.

In comparison to other statistics analysed by ‘in the ditch’

methods, ROSEN’s innovative RoMat service delivers a high

resolution strength profile of the entire examined pipeline section.

There is no longer a need for critical assessments because the pipe

properties of every joint are known. The pipe grade assessment

concludes with a report of the specified minimum yield strength

(SMYS) according to the ASME B 31.8 and the API 5L.

This makes ROSEN’s technology for RoMat ILI services first

choice for regulatory requirements to guarantee safe service

conditions.

The key advantages are:

)

Rebuilding of pipe property SMYS for entire pipeline sections.

)

Completion of known SMYS gaps in pipe tallies.

Figure 3.

Review and reporting of aligned records in Alignment

Sheet.

Figure 1.

Diagram showing the relative pipeline installation by

decades with a maximum in the 1960s.

Figure 2.

Schematic view of ROSEN’s integrated approach.

46

World Pipelines

/

JANUARY 2015