high voltage power lines affecting corrosion growth. In addition,

operational pressure histories let us calculate fatigue effects in

the presence of corrosion or other defects, including how this

changes over time.

Pipeline integrity should not be treated as an island within

an organisation, becoming disconnected from the rest of the

business. The fitness for service, reliability and risk levels of a

pipeline are critical in optimising and managing operational

performance and risk. This perspective illustrates how valuable

inline inspection data can be to a pipeline operator. Control

rooms and asset performance teams must provide on-time,

accurate and consistent information to other departments

within the organisation to set the stage for optimal and

time-critical decisions that impact safety and operational

performance. For example, asset condition

affects potential throughput and security

of supply. In order to ensure that this is

best managed, it must be integrated with

state-of-the-art network optimisation and

planning tools, such as DNV GL’s Synergi

Gas or Synergi Pipeline Simulator. Close

links must also be made to control room

applications, for example leak detection

solutions, such as that provided by Synergi

Pipeline Simulator. In this application we

view our probability of failure of a pipe

segment, as calculated in our integrity

analysis, as the probability of a leak in

that pipe segment before taking account

of any live operational SCADA data. Of

course time factors and failure probability

over time due to condition degradation

must be taken into account. Pigging data

can therefore be used to tune sensitivity

in leak detection relating to corrosion or

stress corrosion cracking factors. Other

data sources, for example call-before-you-

dig or tracking company field activities

from a work management system, could

provide the same input for potential

third party incidents. Combining these

has the potential to greatly improve leak

detection performance and as part of

an emergency response system can be

critical in determining effective responses

and follow-up actions in the case of

incidents.

Overlooked information

sources

One of the largely overlooked and

certainly underutilised information sources

is that described in big data terminology

as unstructured data. This is data that

is not stored in the typical relational or

spatial databases, such as field reports,

email communications or reports with

expert opinions and exchanges including

understanding from domain and

pipeline-specific experts. Think also of

those companies that use internal social media for business

purposes. On platforms such as Yammer, junior and senior

engineers alike exchange valuable information daily, on

operational and more general professional subjects. How can

we make any possible use of this? Well, think of Google, and

how they crawl through websites and pick up keywords and

expressions, making the empirical correlation with search terms

to return content of potential interest, including a priority rating.

Think of the power this could bring to help understand the

cause of specific conditions and possible problems with your

pipeline. Now combine this with input from more conventional

sources, such as the results of the advanced analytics described

earlier and you begin to see the future of pipeline integrity

analysis.

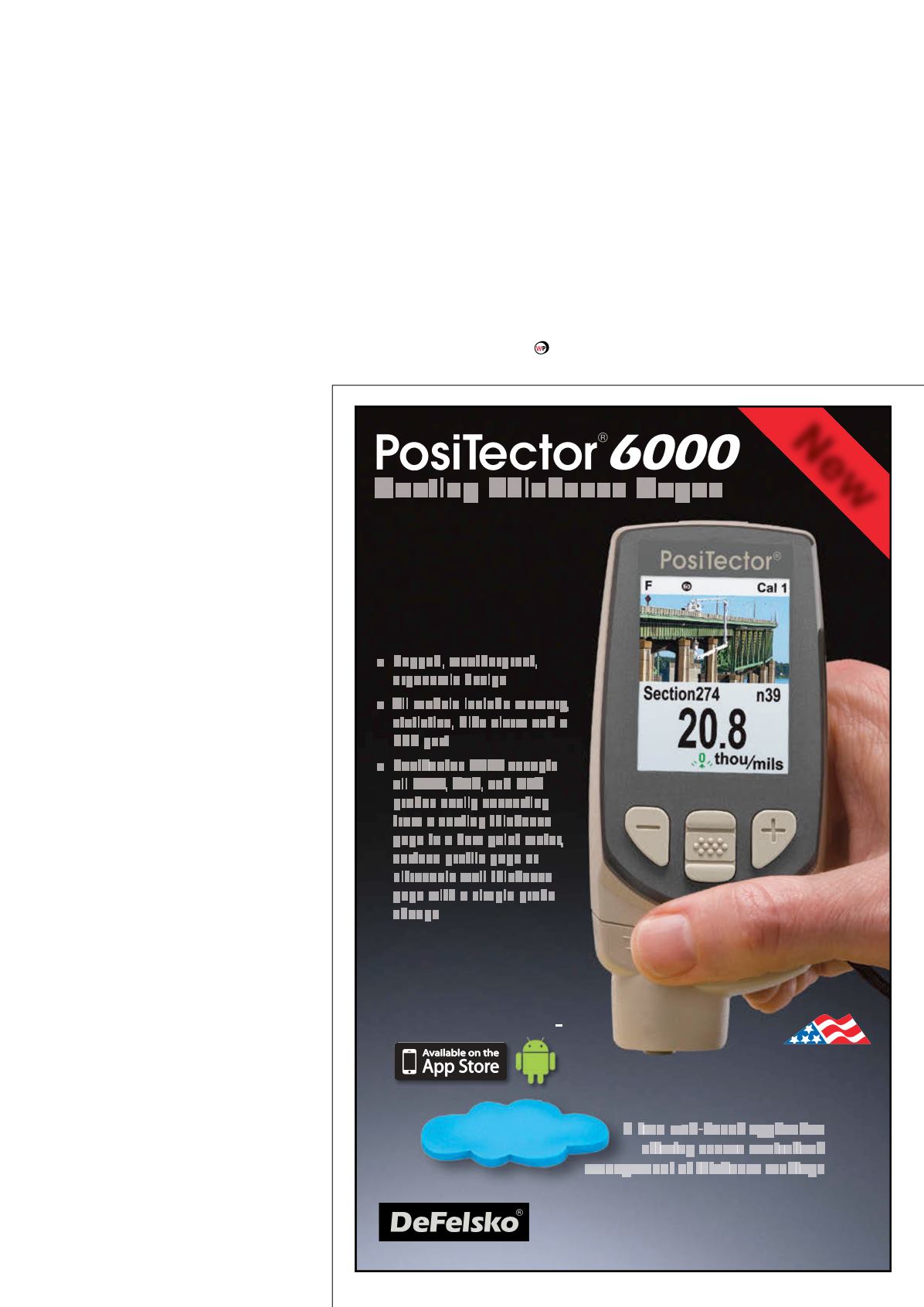

New

Coating Thickness Gages

Now Advanced models come

with

WiFi

and

PosiSoft Mobile

for complete portability

and expanded functionality.

n

Rugged, weatherproof,

ergonomic design

n

All models include memory,

statistics, HiLo alarm and a

USB port

n

PosiTector 6000

accepts

all

DPM

,

SPG

, and

UTG

probes easily converting

from a coating thickness

gage to a dew point meter,

surface profile gage or

ultrasonic wall thickness

gage with a simple probe

change

A free web-based application

offering secure centralized

management of thickness readings

Made in U.S.A.

Advanced model

The Measure of Quality

DeFelsko Corporation

• Ogdensburg, New York

+1 (315) 393-4450 •

1-800-448-3835

Simple.

Durable.

Accurate.