release from within a pipeline system, the consequences can

be minimised by:

)

)

Reducing the time required for detection of the release.

)

)

Reducing the time required to locate the release.

)

)

Reducing the volume that can be released.

)

)

Reducing the emergency response time.

The volume of an unintended release depends on the

leak rate and the length of time before the leak is detected,

with the leak rate in turn primarily dependent on the pipeline

pressure and defect hole size. In order to determine the

impact that any leak detection technology would have on

limiting the spill size, some understanding of the leak rate

distribution would be required. Unfortunately, the majority

of the release data catalogued in North America only

captures the total release volume (such as the PHMSA dataset

discussed earlier). To circumvent this problem, a methodology

and dataset published by Det Norske Veritas, Norway, (DNV)

was applied that provides the hole size distribution for

hydrocarbon equipment including pipelines.

From this data,

3

it can be derived that leaks

caused by smaller diameter holes occur

much more frequently than leaks due to

larger holes. Intuitively this makes sense as

corrosion processes are not likely to result

in a very large diameter hole instantaneously

but rather allow a hole to grow in size over

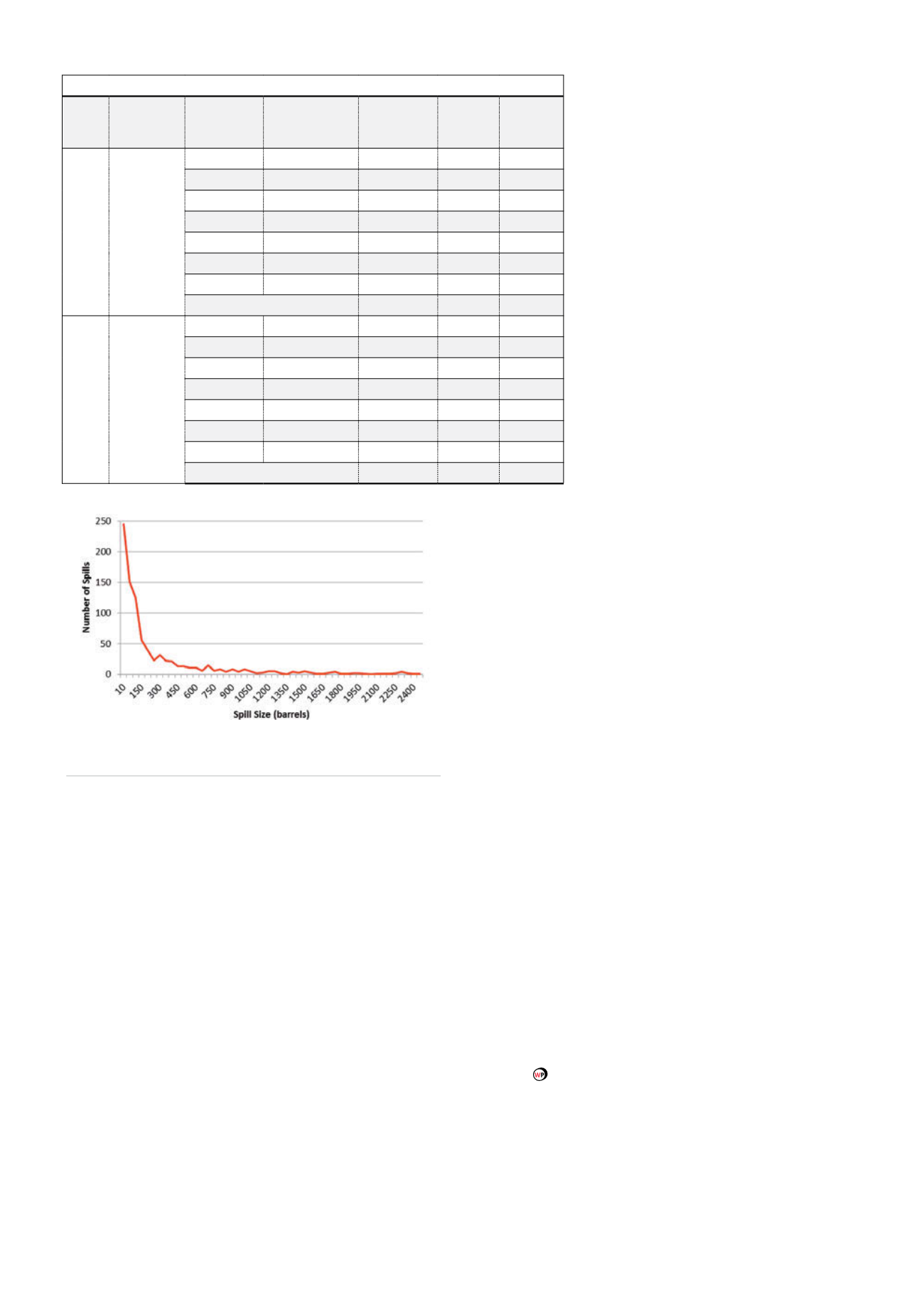

time. The PHMSA data discussed earlier also

seems to support this indirectly through

its distribution of total spill amounts as

presented in Figure 6.

The pipeline aerial surveillance frequency

for the realSens technology is driven

primarily by the goal to reduce the volume

of product that can be released due to a leak

caused by a pinhole. As established earlier, a

SCADA/CPM system will typically be capable

of alarming leaks down to about 1% of the

pipeline flow. For a 100 000 bpd pipeline

operating at 5000 kPa, this would correspond

to a significant 1000 bpd leak rate originating

from a 6 mm dia. hole.

The lower end hydrocarbon leak rate sensitivity threshold

for Synodon’s technology is around 4.5 bpd. The hole size

that would result in a leak of this magnitude from the pipeline

conditions presented above is 0.4 mm.

Let us consider two surveillance intervals for this analysis:

30 days and 90 days. Since the likelihood of a leak developing

is randomly distributed over these intervals, we can use the

midway point for a typical case analysis and the entire interval

as the worst case scenario. Table 1 lists the largest spill amount

that a leak caused by a 0.4 mm hole would be limited to by

using realSens.

Other holes sizes can develop in the pipeline than the

smallest one detectable by Synodon’s system and in general,

the leak rate increases with the square of the defect radius.

At the same time however, the likelihood of larger holes

developing decreases linearly with the radius. To illustrate this,

the numbers in Table 2 have been calculated for a 0.8 mm

defect using the same assumptions as presented in Table 1.

From Andy Bolsover et al, we can extrapolate that the

likelihood of a 0.8 mm defect developing in the pipeline is

roughly half (50%) that for a 0.4 mm hole.

3

Conclusion

The limitations of the existing SCADA/CPM systems highlight

the need to enhance the detection of leaks below 1000 bpd.

Synodon has demonstrated its realSens technology’s ability at

detecting these small leaks down to approximately 4.5 bpd.

Given this new capability, a pipeline operator can determine

the optimal surveillance frequency based on their unique risk

profile and desire to limit the maximum size of a potential

release.

References

1.

US Department of Transportation (DOT),

Pipeline and Hazardous Materials

Safety Administration (PHMSA)

: Leak Detection Study – DTPH56-11-D-000001.

2.

API Standard 1160: ‘Managing System Integrity for Hazardous Liquid Pipelines’,

First Edition, November 2001.

3.

BOLSOVER, Andy, et al (2013), A Public Leak Frequency Dataset for Upstream and

Downstream Quantitative Risk Assessment.

Figure 6.

Distribution of US spill sizes, significant leaks,

2002 - 2009.

Table 3. Detection results summary

Series N

2

flowrate

(scfh)

Pass no.

Mass (kg)

OSA

evaporation

rate (g/min)

Wind

direction

Detection

1

250

0

28.30

-

-

-

1

28.28

20

NNW missed

2

28.26

20

N

no

3

28.22

40

NNE

yes

4

28.18

40

NNE

yes

5

28.16

20

W yes

6

28.12

40

SW no

Average OSA evaporation rate: 30

-

-

2

500

0

28.84

-

-

-

1

28.78

60

S

weak

2

28.7

80

S

missed

3

28.64

60

SW yes

4

28.6

40

SSW yes

5

28.56

40

S

yes

6

28.52

40

SE

yes

Average OSA evaporation rate: 55

-

-

30

World Pipelines

/

JANUARY 2015