156

World Pipelines

/

AUGUST 2015

In-house training programme

An in-house training programme is effective but can also be

very costly and time consuming. The advantage of creating

your own in-house course is that it will reflect your company’s

culture and way of doing business. The key is getting the

right people together to build and implement a training

programme. Building a training course is not something that

should be left up to the company’s safety department to

create in isolation; it needs to involve experienced operators,

equipment managers and mechanics to ensure the programme

reflects real world operations.

So, what should be included in your training course?

Start with the legislated requirements in your jurisdiction

or the jurisdictions in which you operate, always default

to the highest standard. By doing so, you are always

compliant.Next, look to any consensus standards relating

to pipeline equipment

operation, such as the

American Society of

Mechanical Engineers

Standard ASME B30.14 Side

Boom Tractors. This standard

is full of information on side

boom operations including

qualifications for operators

and inspection requirements.

Client requirements are

also a good source of

information. Many large

pipeline operators have

specific procedures or

standard operating practices

that they expect equipment

operators to know and

follow while working on

their spreads, which will add

value to your training. Most

health and safety legislation

requires that equipment be

operated in accordance with

manufacturer’s recommendations contained within the

machine’s manual; including the manufacturer’s instructions

in your training programme is a must. Lastly, your

training needs to be include your company’s policies and

expectations on how machine operators use and care for

your equipment. Once you have developed your training

programme you then have a standard to evaluate machine

operators against in order to deem them competent. As

with every training programme, there needs to a practical

component that allows the machine operators to take

the knowledge they gained from classroom education and

apply it in the field in a controlled environment under the

watchful eye of an experienced operator.

Deeming competency

The age old question; who is qualified to deem pipeline

equipment operators competent? This is one of those chicken

and the egg scenarios. Remember that someone had to be

the examiner for the first drivers test. Safety regulators often

define a qualified person as someone who is knowledgeable in

their area of work, the hazards involved, and the methods to

control those hazards. Once you have developed your training

programme using regulatory requirements, industry standards,

best practices and machine manufacturer’s instructions for

the safe use of the equipment, you have pretty much covered

those bases. This is where having experienced operators

involved in developing your training really pays off. Having

your experienced operators demonstrate the competencies

that they helped develop as part of the training programme

allows you to ‘test drive’ your programme to ensure you

have it right. Then the operators who helped develop the

programme act as your evaluators to assess the rest of your

machine operators.

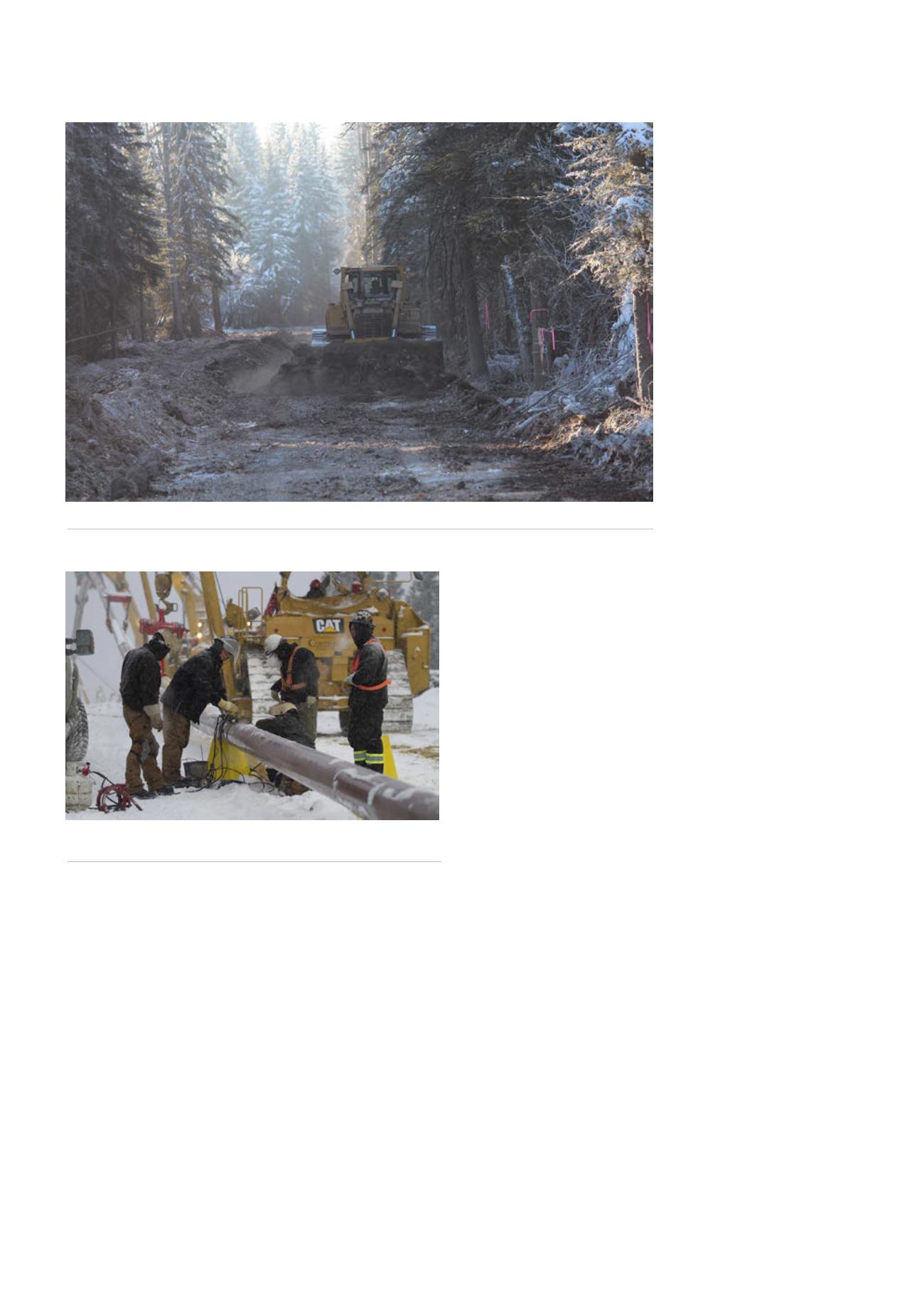

Figure 3.

Pipeline operations are often within a machine’s

safety zone.

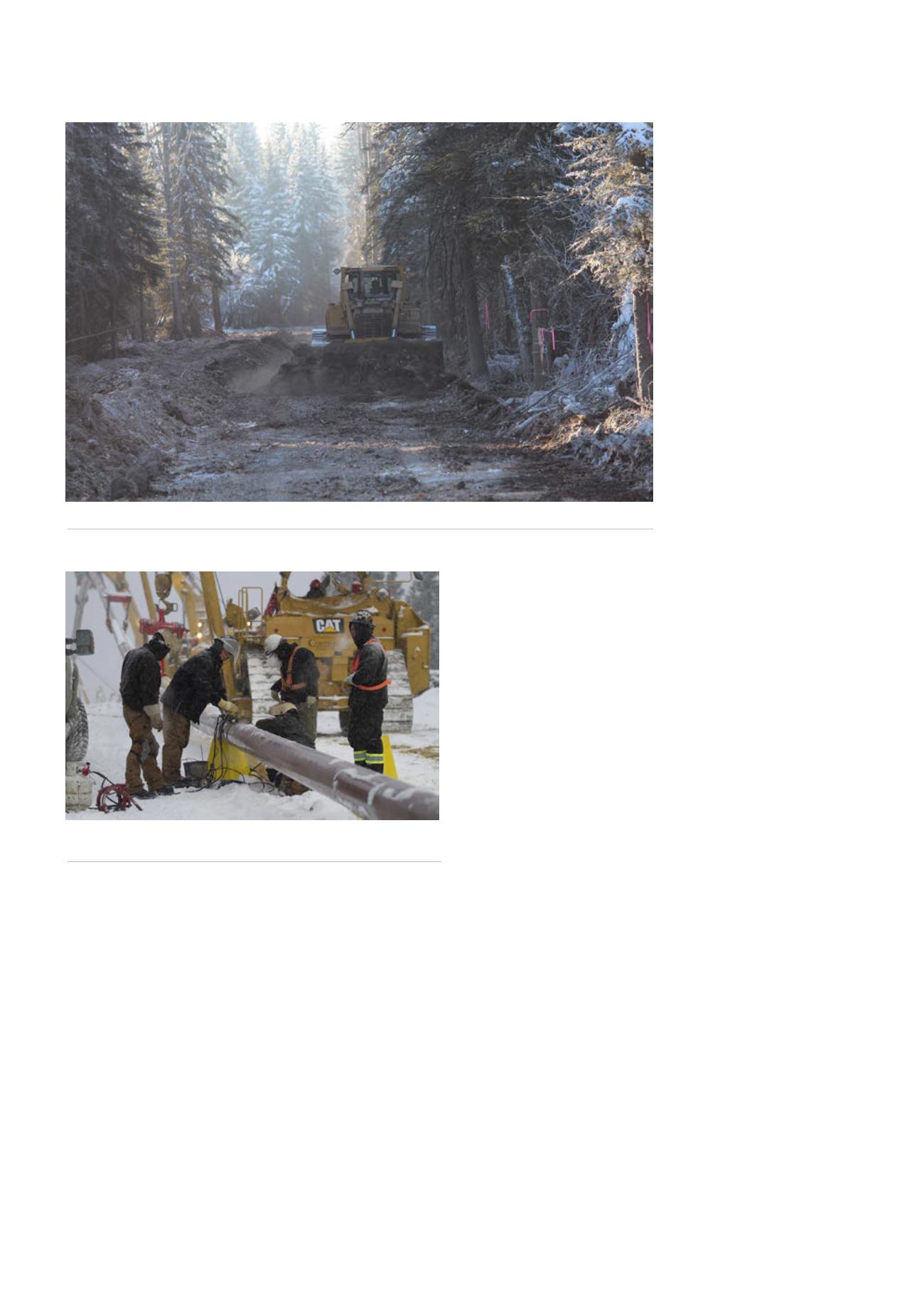

Figure 2.

Ensure the operator sees you before entering the safety zone.