combination with a recycling machine because it does not

have extra additives, which can obstruct the screens. The

drilling fluid was checked continuously during mixing, upon

return to the recycling unit, and then finally when it came

out of the recycler. When necessary, the mud-engineer

could instruct to adjust the bentonite content, increase it or

dilute it.

For the lubrication of the tunnel, Tunnel-gel Plus in

combination with some additives was used. PAC-L has been

added to give a stronger filtercake in the several formations,

which had to be passed. When the formation became too

coarse, a fibre (IPR-007) in combination with the PAC-L was

added to the bentonite, which sealed the coarse formation

completely. The fibre fixes the coarse formation and creates a

kind of spider web, reducing the pores). The bentonite and the

PAC-L can easily attach themselves to the fibre and seal the

formation.

During the drilling it was noted that, when adding a

lubricant (IDP-605) to the bentonite, the friction was reduced

by half. In addition to using the correct type of bentonite, the

total fluids system resulted in extremely low pushing forces

and drilling speeds of up to 40 m/day.

Inter-jack stations: available but not used

Since the geological conditions were expected to be complex,

it was decided to install inter-jack stations at approximately

every 150 m. In case of unexpected circumstances, which could

cause temporary increase in pushing force, then the inter-jack

stations would be available for support. However, none of

the stations has been required for such complementary push

force. Only after a temporary suspension of the pushing during

replacement of the cutting disks the inter-jack stations were

used to assist in the resumption of the pushing.

Underwater cutting disks replacement

At a distance of 178 m from the starting point, it became

clear that the cutting disks needed replacement. As the

disks are placed in front of the machine, whilst the machine

is submerged under the river’s soil, divers had to enter the

machine’s head front door to access the disk slots and replace

the disks.

Stringent safety requirements

The HSE requirements for an accessible subsurface tunnel

of this length were obviously significant and stringent.

Maintenance and inspection crew were entering the tunnel on

a daily basis, up to the machine at the end of the tunnel. For

the purpose of increasing safety, A.Hak Drillcon has used an

entire range of navigation, survey and monitoring technology

from Herrenknecht’s subsidiary VMT. Using IRIS.microtunnel,

a webbased data management and monitoring system, it was,

among other things, possible to permanently monitor all

support pressures while comparing them in parallel with the

fluctuating tides of the Elbe.

The safety concept of the site is realised through the

communication infrastructure HADES: The wireless and fibre-

based system is a supplier of video images and gas detection

values, provides the network connection for the installed

geoscanne, equips the staff on site with mobile phone and

integrated gas and fire alarm and provides an access control

into the shaft via RFID tags.

Gas pipelines pull-in

Upon completion of the concrete tunnel, the two 750 mm gas

pipelines were pulled into the tunnel with assistance of one of

A.Hak Drillcon’s HDD rigs. The drill rod was led into the tunnel,

connected to the pulling head of the pipelines, and supported by

carriages, the pipelines were pulled into the tunnel towards the

HDD rig.

Grouting after completion

When the pipelines and the HDPE conduits assembly had been

pulled into the tunnel, a final inspection took place. Then upon

acceptance of the pull-in operation, the empty space between the

assembly and the tunnel was filled entirely with grout, rendering

two gas pipelines and the conduits as encased in one solid

concrete underpass under River Elbe.

A high profile project

A high profile project has been completed successfully. This

tunnel ranks amongst the largest microtunnelling projects in the

world!

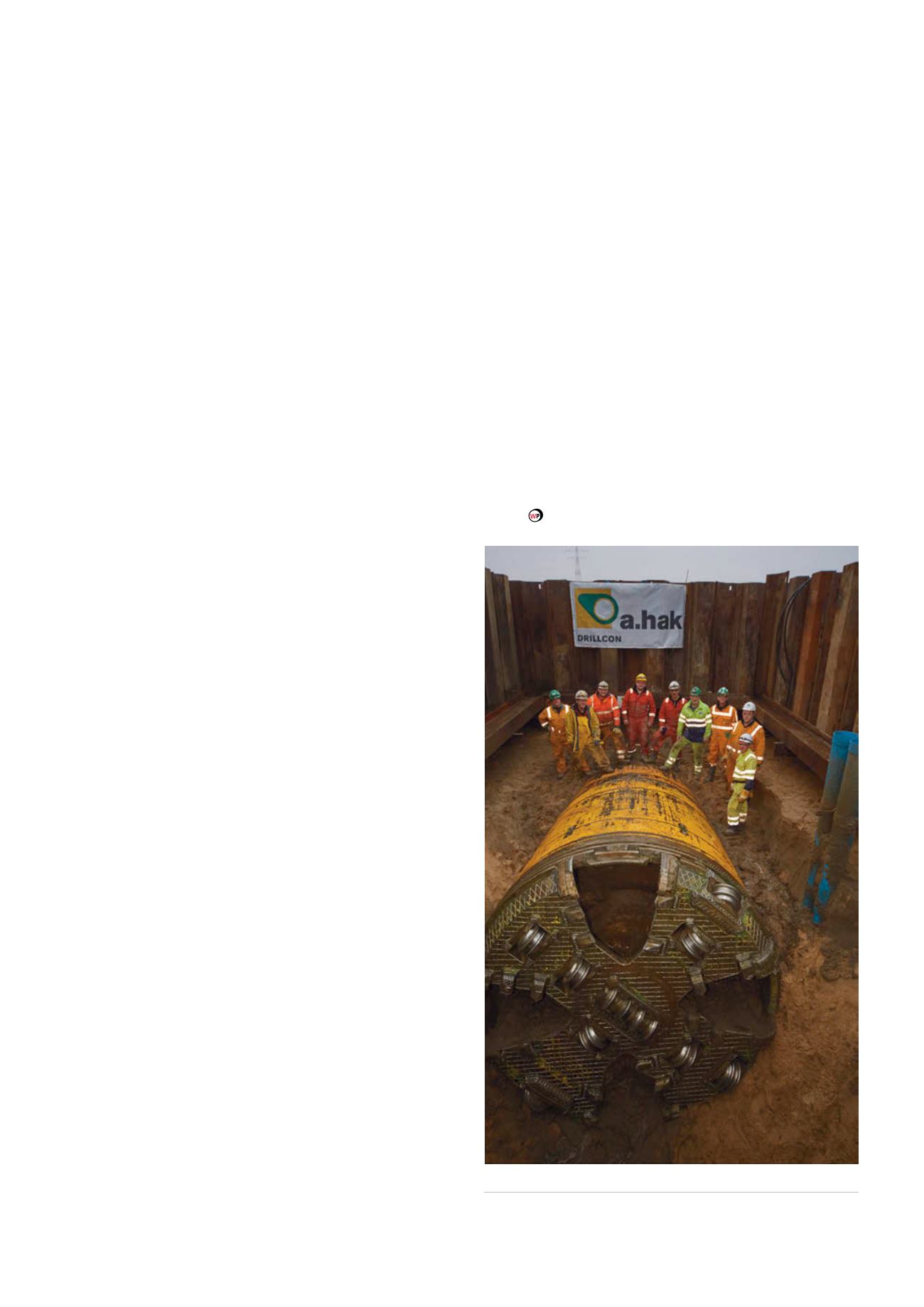

Figure 3.

Emerging in the reception shaft on Lühesand Island.

AUGUST 2015

/

World Pipelines

151