line in operation. There is no heavy equipment required

or expensive skilled labour costs. Some composite repair

systems will achieve full cure in two hours then be ready

for re-coat then backfill. However, not all composites are

created equally. There are attributes of each system that

affect its installation, performance, and durability.

There is, however, one commonality that every

composite system shares, and that is the method in which

they repair anomalies in pipe wall. The concept is similar

to that of a steel sleeve, a high modulus filler material

is used to transfer the stress experienced in a defect in

the pipe to the encompassing sleeve/wrap. This filler

material, held in place by the outer sleeve, prevents the

damaged area from bulging and subsequently fracturing.

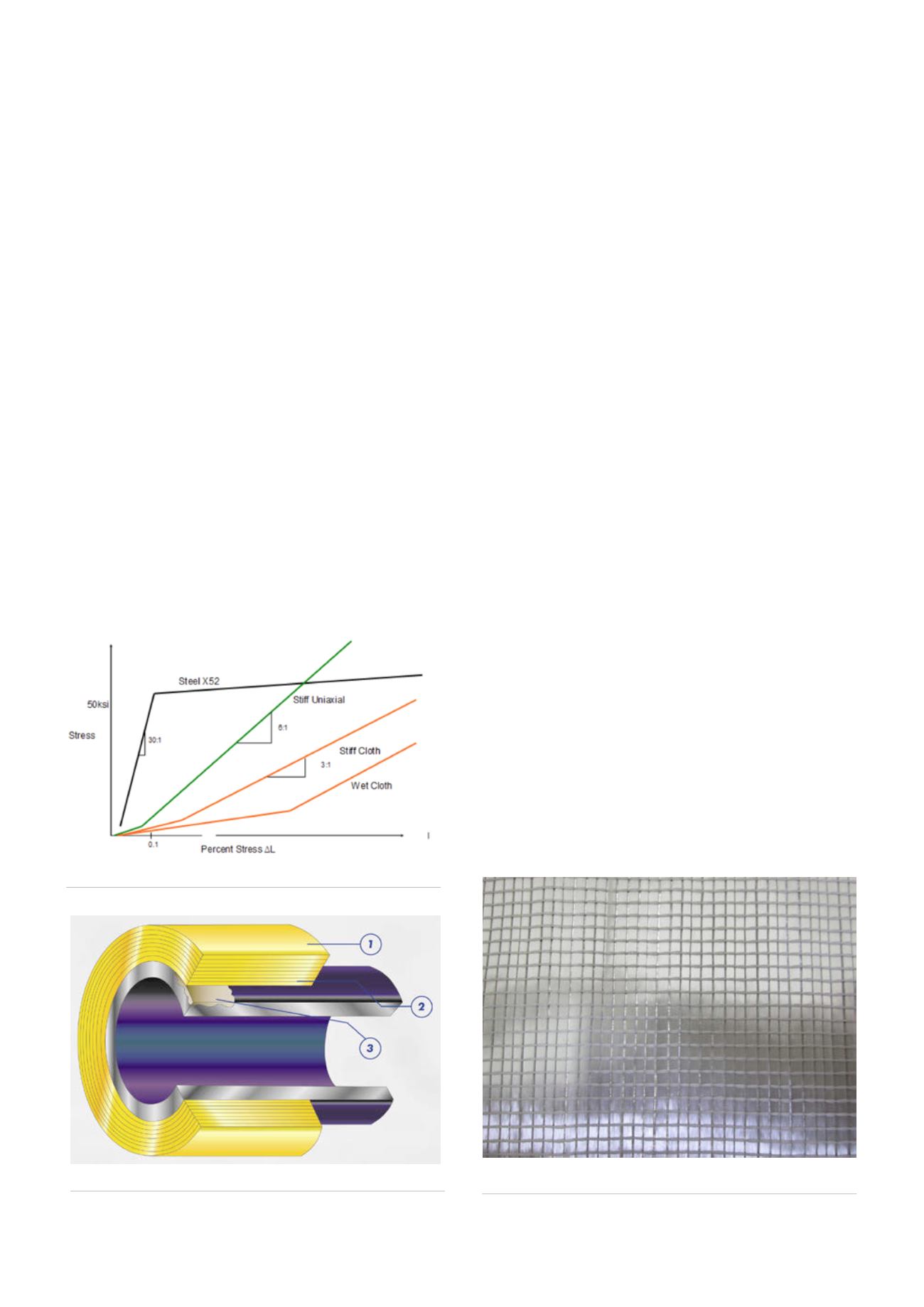

In a situation where a pipe is subjected to a high

enough stress, the steel enters what is called a plastic

region, in which the steel will experience a large strain

in relation to the amount of additional stress (this is

represented by the nearly horizontal section of steel line

in Figure 1). It is in this region that the composite takes

up the load felt by the steel and begins to assume any

added stress, preventing the steel from fracturing. Due to

the inherent nature of most composite systems designed

for high pressure pipeline repair, they are less stiff than

steel, and that is why they do not perform until the steel

begins to deform plastically. This can be seen in Figure 1,

specifically the ‘stiff uniaxial’ composite. Stiffness, or, the

modulus of elasticity, is represented in the figure as the

slope of each line. The slope can be considered stiffness

because it displays how much each material will strain for

a given amount of stress.

Different composites architectures

A point of distinction needs to be made between the

different composites architectures. All composites are

composed of a strength member and a bonding matrix. For

high pressure pipeline applications, the strength member

is typically ‘E-glass’ or electrical grade glass fibres.

E-glass was selected for most rigid composite sleeves

because of its high strength (tensile strength of 500 ksi),

electrical properties, availability, and compatibility

with the selected resin (matrix). An isophtalic polyester

resin is sometimes chosen as the matrix due to its low

moisture absorption, excellent resistance to chemicals,

and good thermal properties. To create this stiff uniaxial

composite, 600 000 strands of the E-glass are combined

with the liquid isophthalic polyester resin, wound around

a cylindrical mandrel then allowed to air cure. Hardening

in this orientation allows the composite to retain a

cylindrical shape memory, and in turn it will conform

snugly to the pipe without introducing any kinks or stress

concentrations in the composite’s strength members

(fibres). This specific architecture is deemed ‘uniaxial’

because all of the fibres are oriented in one direction, the

‘hoop’ direction. The fibres are continuous strands around

the entire cylindrical sleeve, which is eight revolutions

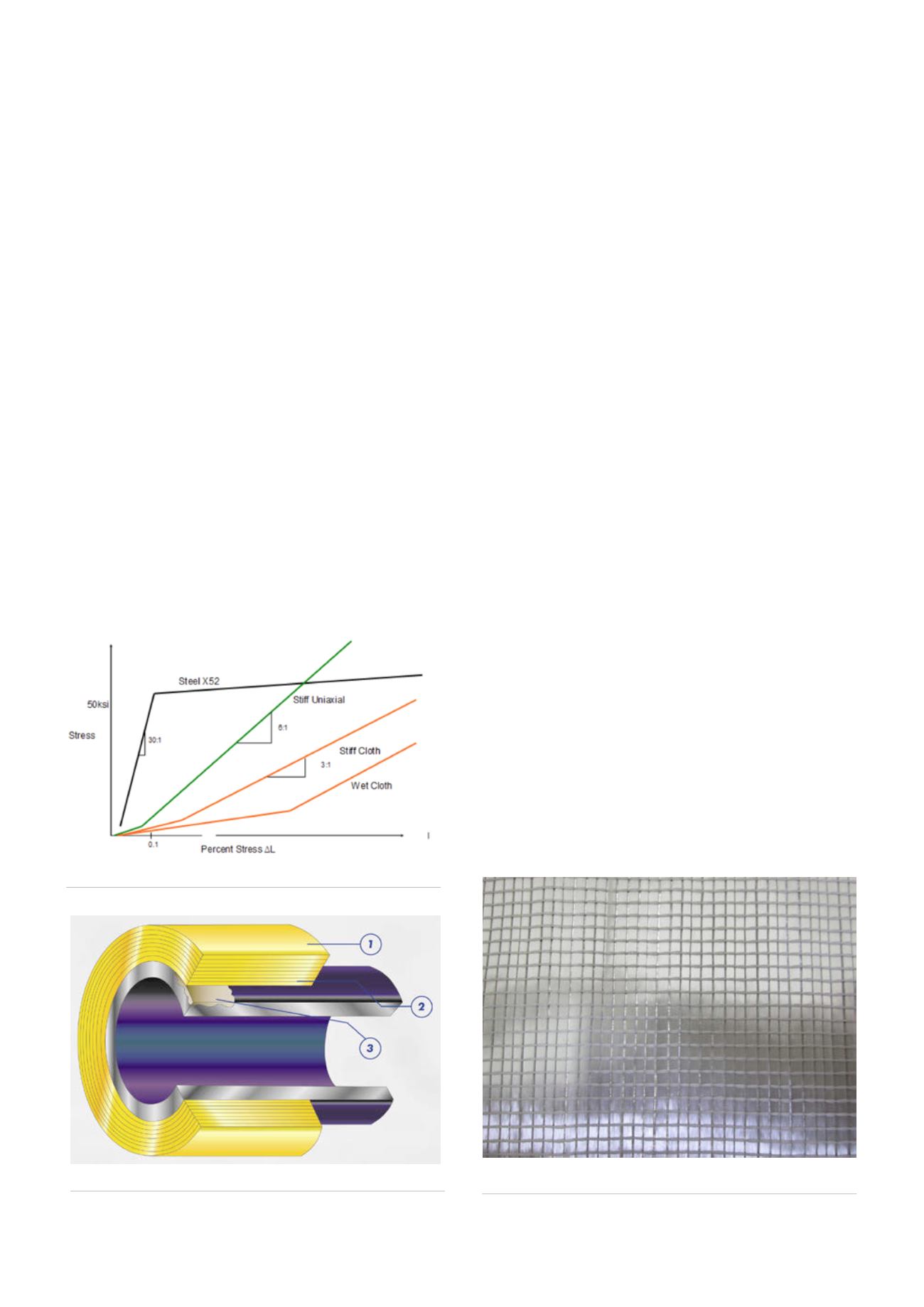

or ‘layers’ around the pipe. Figure 2 shows the essential

pieces of a rigid composite repair: the composite sleeve,

the adhesive between each layer

2

and on the pipe, and

the high stiffness filler material.

3

The ‘stiff cloth’ architecture is similar to the previous

example in that the glass fibres are combined with a liquid

resin, wound on a cylindrical mandrel, and then allowed

to air cure. The difference being the strength member is a

Figure 1.

Graph showing steel subjected to stress.

Figure 2.

Rigid composite repair.

Figure 3.

Tensile strength and modules of elasticity were

analysed.

146

World Pipelines

/

AUGUST 2015