loads, and parking heavy equipment on a steep slope

requires detailed planning and is work for competent

and experienced supervisors and operators who possess

a specific knowledge and skill set, as described in this

article.

The worksites and access roads on slopes are distant

from management offices and supervision and usually

vehicle drivers and heavy equipment operators find

themselves facing steep slopes alone. Identifying and

managing the risk of ascending or descending these

isolated slopes requires adherence to a safe work

procedure which, in its preparation, has considered the

hazards and details a system of controls to mitigate the

risks in the absence of supervisory control.

In mountainous terrain, each slope should be measured

separately to identify how steep it is. Slopes are measured

in two ways, not to be interchanged: degrees of slope (as

an angle of inclination to the horizontal), or percentage

of grade, (which is in terms of length of rise or drop, per

length of horizontal distance).

Once the slopes are measured, a safe work procedure

will require the classification of the different degrees

of slope from zero to extreme. A simple system, which

works well, is to colour code the different classifications

of slopes on a project road access and ROW map. Onsite,

colour coded physical markers are erected at the top and

bottom of the slopes:

)

)

0 - 7° normal slope – classified green.

)

)

7 - 15° medium slope – classified yellow.

)

)

Above 15 - 25° steep slope – classified blue.

)

)

Above 25° extreme slope – classified red.

The defining degrees for each classification of

slope varies from project to project, at the discretion,

experience and confidence of the contractor’s

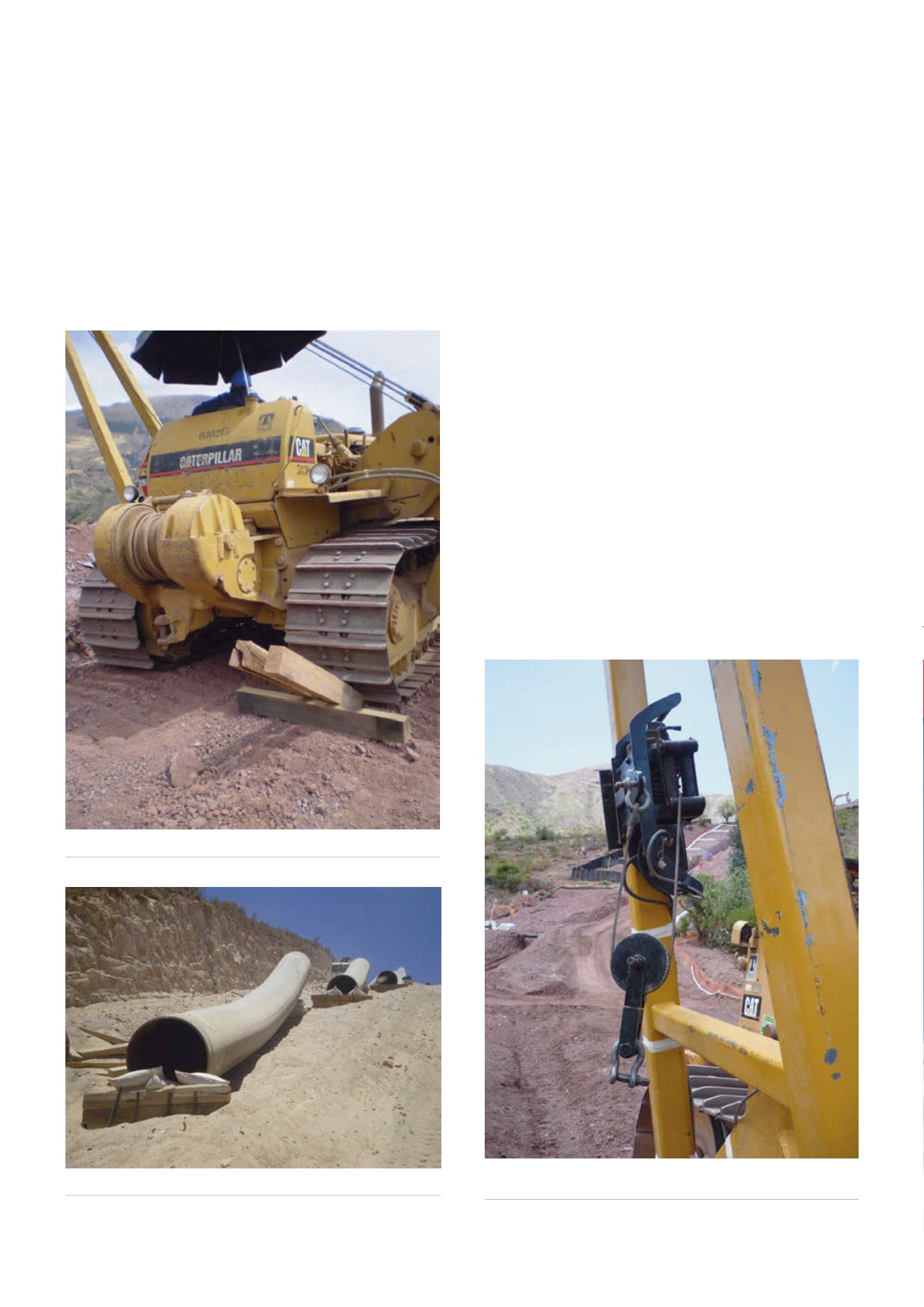

Figure 2.

Blocking of tracks with skids when parking on slope.

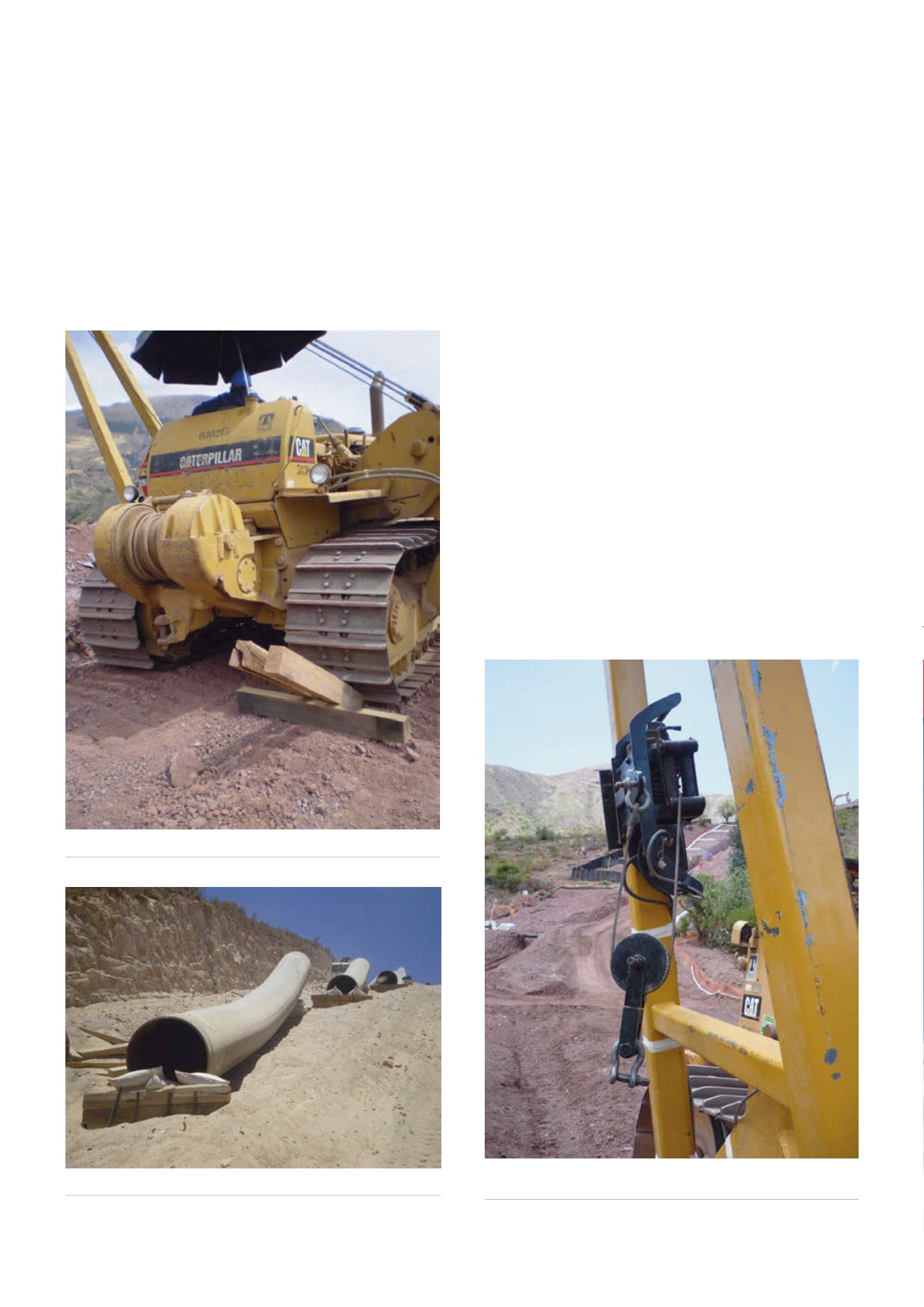

Figure 4.

Retractable device to secure the load close to boom

when ascending or descending a slope.

Figure 3.

Strung pipe joints prevented from sliding down slope.

162

World Pipelines

/

AUGUST 2015