)

)

When the side boom climbs a slope, an unsecured load

may hang far enough back to cause an upward and

rearward shift of the C of G, which can fall dangerously

close to the tipping point. Securing the load to the

boom maintains the C of G within the base of the

tractor and within acceptable limits.

)

)

Stalling or inadvertent shutting off of the engine may

result in loss of control and runaway of an older model

tractor with hydraulically assisted, mechanical-linkage

brakes. Have the breaks adjusted to manufacturer

specifications before deployment to slope work areas.

)

)

Breaking over the crest of a hill too quickly, where

the distance the boom head travels is greater than the

distance the tractor travels, causes the load to swing

forward since the boom head speed is momentarily

greater than the ground speed of the tractor. This rapid

shift in load may cause the tractor to tip over.

)

)

When equipment is not in use/standby position during

construction on a 15 - 17˚ slope, it will have its tracks

blocked with wooden skids, earth berms or other

method, unless soil conditions or the weather make

the slope and soil conditions more unstable, in which

case winching and anchoring may be required.

)

)

Pipe sections and/or dead man winch tractor may need

to be secured with an anchor such as a water filled,

buried pipe joint, a D8/10, Excavator or 594 side boom.

A dead man tractor should be of sufficient size and

equipped with an adequate winch assembly to hold and

support the side boom tractor working on the slope, in

the event that the side boom being supported loses all

power. The dead man winch tractor should be secured

whenever possible to a fixed object further up the

slope for additional safety.

)

)

Single strung pipe joints may need to be prevented

from sliding down slope.

Boom operators

When operating side booms on slopes, the stability of

the tractor is the major concern. There is no such thing as

drive by numbers. Operating a side boom on a steep slope

is an acquired skill, a seat of the pants operation. There

is no hard and fast formula for where a load should be

carried – boomed up or out. It has to be boomed out far

enough away from the tractor so as not to tip the machine

fore or aft but not so far as to turn the machine away

from its direction of travel. Evaluating the competency of

side boom operator is essential.

It is vital for the individual operator to have

confidence in his supervisor, who will give him/her

direction, the mechanical serviceability of his machine, and

his own ability. On steep slopes, it is vital to have ample

winching capacity on hand. The need for a winch line

should be assessed early and attached well before there is

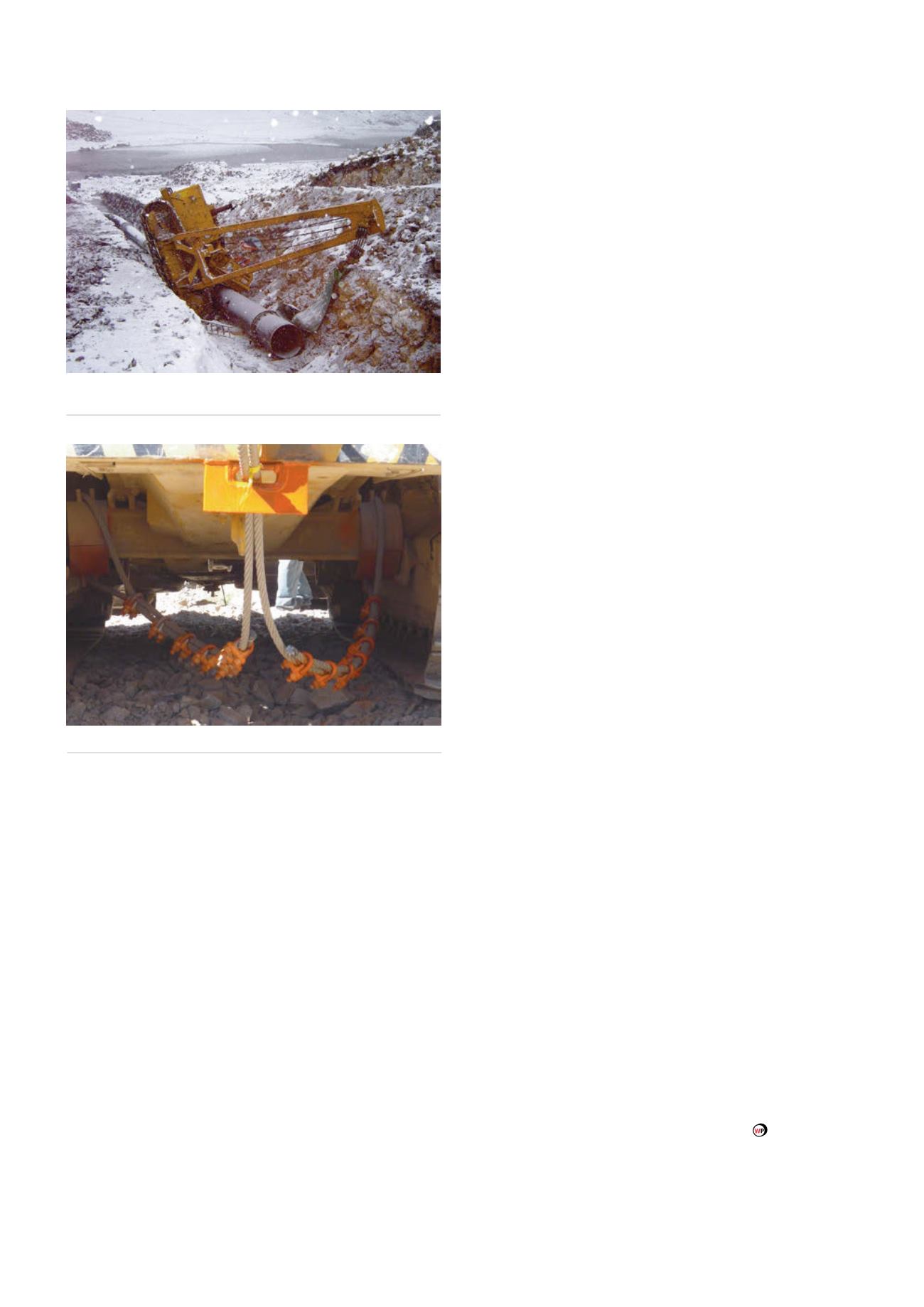

no other option. The hard-bar harness is the best selection

for securing the side boom to the winch line hook.

The wrong attachment point on the tractor can upset

the balance of the tractor under load. Winch tractor

operators must be unquestionably competent. Descending

downhill, operators must select a gear that will prevent

excessive speed and be trained and competent in cross

steering in the event of unexpected loss of traction on the

slope which can occur unexpectedly with minimal rain and

the right soil conditions.

Boom operators packing prep machines must be

cautious when climbing or descending steep hills – weight

of end prep machine hanging off at an angle to the boom

can pull a side boom tractor over.

Parking equipment on hills – set parking brake lever;

turn sideways to slope; dozers drop blade, dig in corner

bit.

If you leave equipment unattended always push the

safety lever down, which locks the transmission on the

transmission shifter tower.

When operating on steep slopes, boom operators must

not leave their equipment unattended. Boom operators

must stay on their equipment at all times.

Notes

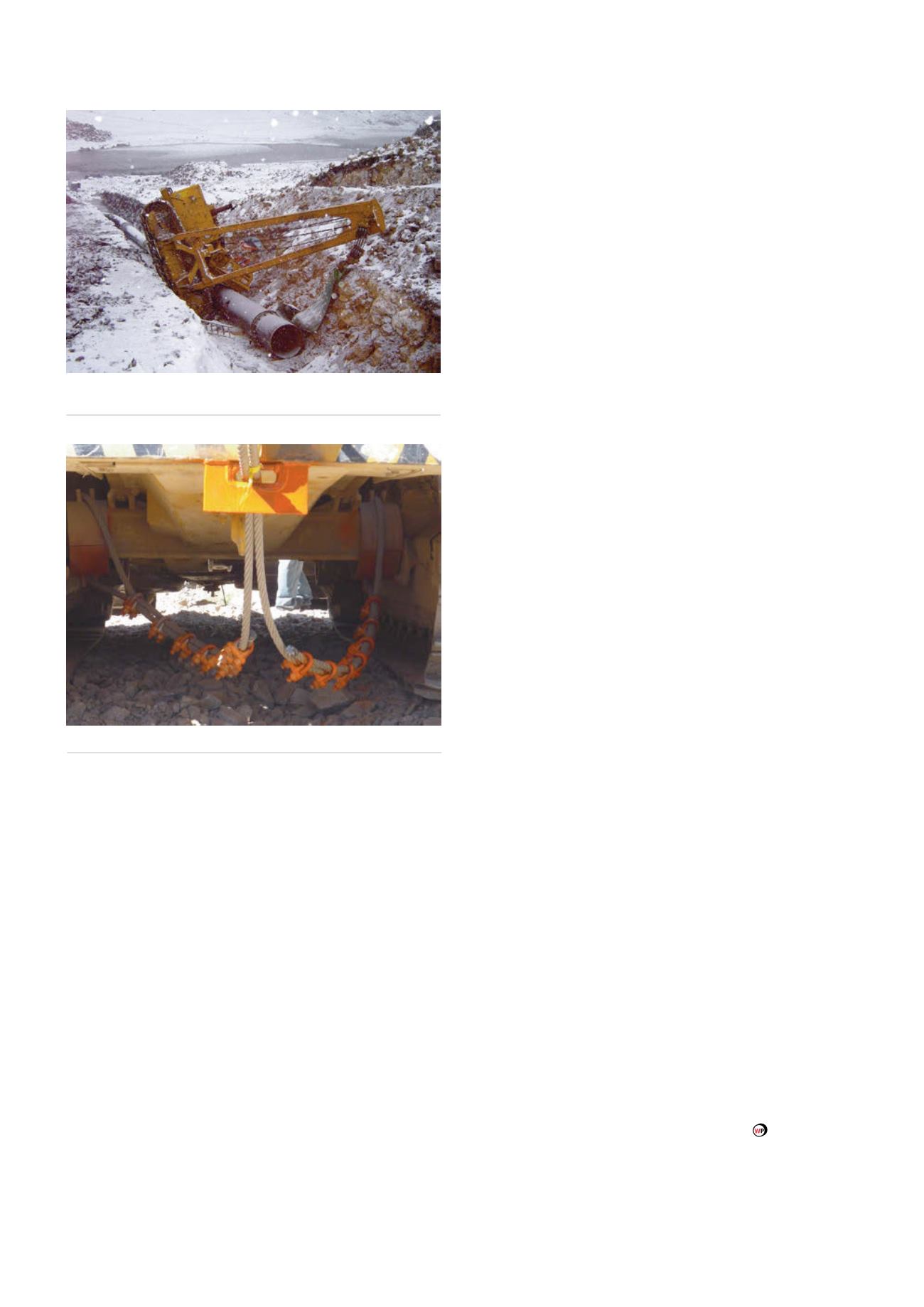

Figure 7.

Consequences of not winterizing your equipment in

sub-zero weather.

Figure 8.

The hard-bar harness provides best tractor stability.

166

World Pipelines

/

AUGUST 2015