158

World Pipelines

/

AUGUST 2015

Third party training providers

There are several companies that specialise in pipeline

equipment training and competency evaluations. The courses

they provide can be tailored to your specific equipment

and operations. Some even offer computer based training

modules that increases training flexibility. Most third party

training providers will come to your project and work with

your equipment and operators onsite, which for many pipeline

contractors is a very attractive option.

Machine safety zones

A way to protect workers from injury while working with pipeline

equipment is the use of machine safety zones. A machine safety

zone includes the maximum reach of the machines boom, stick,

counter weight or other attachment plus a buffer distance for

360˚ around a machine. Workers are instructed to stay out of

the safety zone unless a specific task requires them to be within

the zone. Any worker that is required to enter the safety zone

must first make eye contact with the operator. Once the worker

has made eye contact with the operator, they would then signal

the operator that they wish to enter the safety zone. If it is safe

for the worker to enter, the operator would then idle down

the machine, place any applicable attachments on the ground

and then signal the worker that it is ok to enter. If an operator

notices a worker who enters his machine’s safety zone without

first notifying him and receiving permission to enter, the operator

would stop operations and sound the machines horn if equipped,

to provide a friendly reminder to the worker that they have

entered a potential danger area.

Working inside the safety zone

A majority of the pipeline work such as stringing of pipe,

excavating of existing pipelines, stabbing and spacing of pipe

for welding, requires workers to be within close proximity of

working machinery and often well inside the machine’s safety

zone. In these scenarios, a specific job safety analysis (JSA) or

safe work practice (SWP) relating to the work needs to be in

place and reviewed with all workers involved with the specific

task. The JSA or SWP should detail at a minimum the number

of workers involved, the communication methods to be used

and personal protective equipment required. The review of

the JSA or SWP should be completed during the first tailgate/

safety meeting before starting the particular task or job. To

avoid confusion about who is giving signal to the operator,

one person should always be designated as the spotter or

signal person for the equipment operator. Working near

above-ground piping, power lines and other equipment also

requires a person to be assigned to work with the machine

operator as a spotter. The purpose of the spotter is to alert

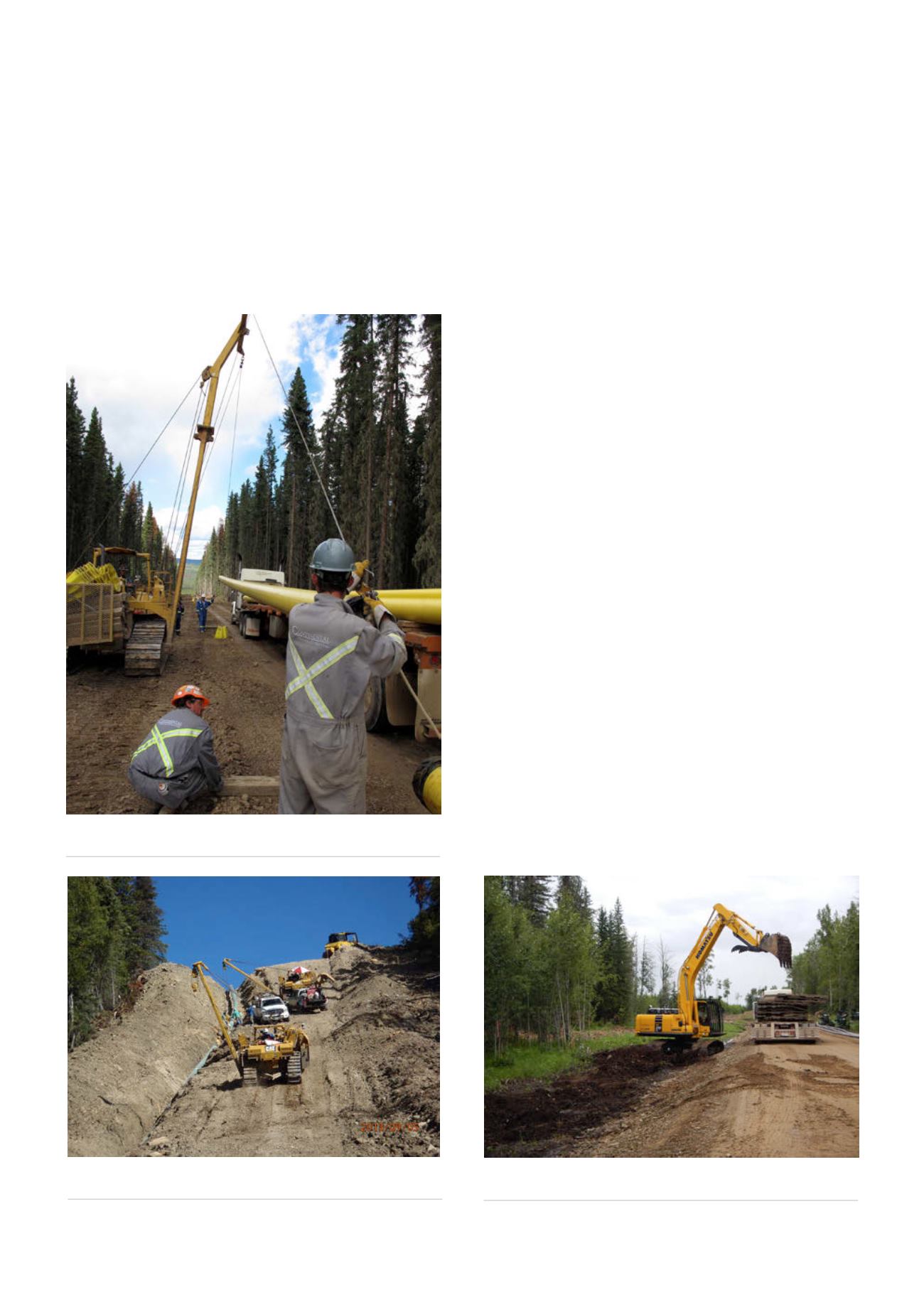

Figure 4.

Clear communication between operator and spotter is

paramount.

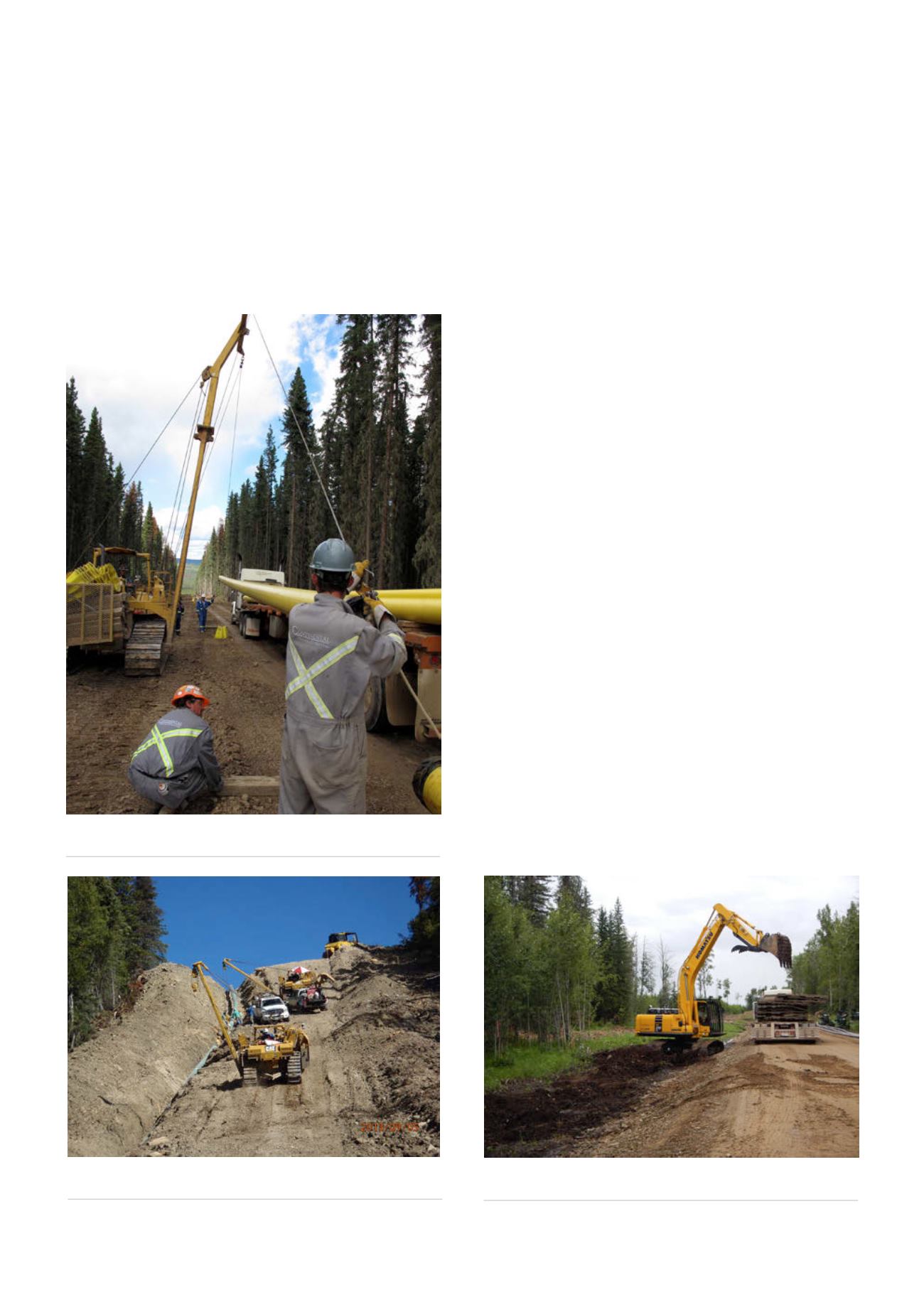

Figure 5.

Steep terrain requires ROPS equipment and good

training.

Figure 6.

FOPS protects operators when moving materials.

Handrails provide fall protection during servicing.