the operator when they are approaching any other equipment

or facilities and to signal the operator either by hand signals

or sounding a warning horn to prevent unintended contact

occurring. The spotter will also assist the operator in

monitoring the machines safety zone and warn others if they

get too close. Clear communication between the operator

and spotter is critical.

Engineering controls

We all know that engineering controls are most effective

when it comes to keeping workers safe when operating

pipeline machinery. With today’s technology there are

a number of options that can improve and enhance the

safety of pipeline equipment operations. Excavators and

other equipment can now be fitted with warning devices

that detect high voltage power lines and provide both an

audio and visual warning signal to the operator when a

machine encroaches on the limits of approach for a high

voltage line. Load monitoring indicators (LMIs) and anti-

two-block devices once only available for cranes are now

available for side booms tractors. These units provide

boom operators with information on hook weight, boom

overhang, machine slope, and machine capacity under its

current configuration. They also provide an audio warning

alarm to the boom operator when the machine is at or near

its maximum capacity which will prevent equipment damage

and boom tip over incidents. The

anti-two-block device also provides

audio and visual alarms to the boom

operator to prevent inadvertent

contact of the hanging blocks

preventing cable and sheave damage

and possible equipment failure that

could endanger pipeline ground

crews. Roll-over protective structures

(ROPS) are available for most sizes and

configurations of side booms now.

ROPS used in conjunction with seat

belts can reduce or even eliminate

serious injuries and operator deaths in

the event of roll overs involving both

crawler tractors and side booms.

Excavators are one of the

most versatile pieces of pipeline

equipment. Fitting an excavator with

a falling objects protective structure

(FOPS) will help protect the operator

from injury by preventing falling or

flying objects from penetrating the

excavator cab. These structures can

also provide additional protection

to the operator in the event of a

tip over as they provide addition

strength to the machine’s cab area.

Falls from pipeline equipment are

a common cause of injury. Ensuring

equipment is fitted with appropriate

handrails, guardrails, steps and foot

holds especially in areas that are

routinely accessed by operators

for service and inspection. This can

greatly reduce fall from equipment

injuries.

Working around pipeline machinery

will always have its hazards. At

Continental Pipeline, one of its core

values is to ‘do the right thing’. Ensuring

that every reasonable precaution to

protect operators and ground crews

when working with pipeline machinery

is always the right thing to do.

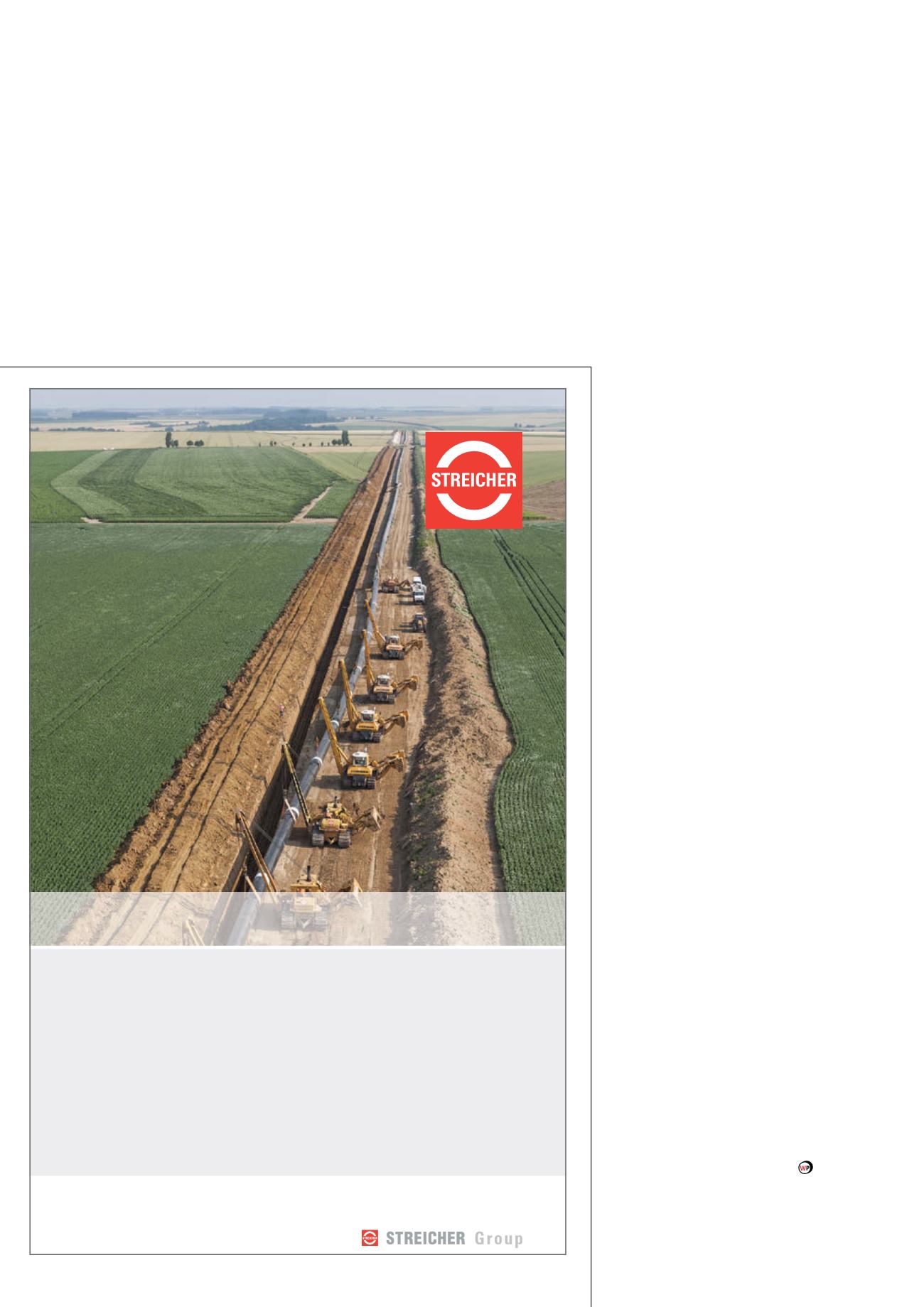

Pipeline and plant construction is one of STREICHER’s core competencies. As an

EPC-con-

tractor for oil and gas pipelines and plants as well as water pipelines and pipelines for

chemical products

, STREICHER carries out all services from planning and construction to

commissioning and maintenance. The

business sector “Drilling Technology”

manufactures

drilling rigs for hydrocarbon and geothermal exploration as well as HDD rigs for trench-

less pipe laying. The sector “Drilling Technology” works closely together with the drilling

contractor

DrillTec GUT GmbH Großbohr- und Umwelttechnik

, a subsidiary of STREICHER.

The

STREICHER Group

, with approx. 3,500 employees worldwide, undertakes large-scale

projects in different sectors, such as Pipelines & Plants, Mechanical Engineering, Civil &

Structural Engineering and Construction Material.

MAX STREICHER GmbH & Co. KG aA

· Schwaigerbreite 17 · 94469 Deggendorf · Germany

T

+49 (0)991 330-231 ·

E

·

www

streicher.de

Drilltec GUT GmbH Großbohr- und Umwelttechnik

Josef-Wallner-Str. 10 · 94469 Deggendorf · Germany

T

+49 (0)991 37212-400·

E

·

www

drilltec.de

MIDSTREAM & UPSTREAM SOLUTIONS

World-Pipelines-Magazine_IPLOCA-Issue_2015.indd 1

16.06.2015 10:28:05